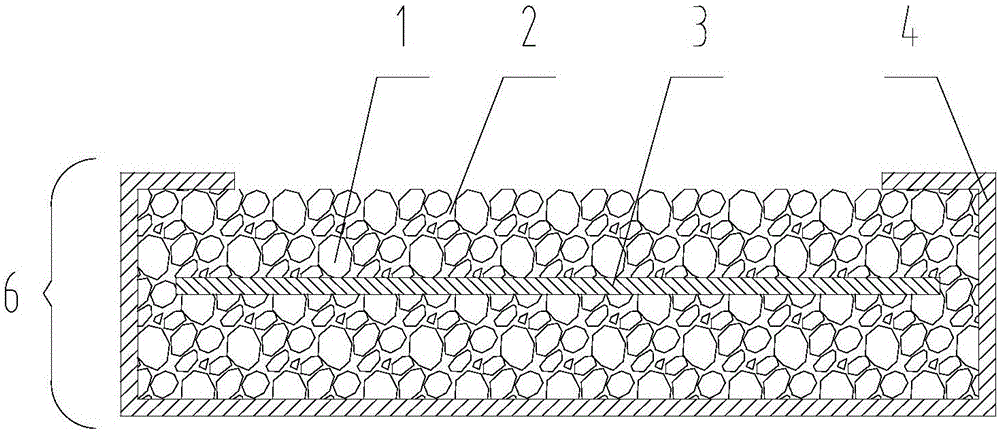

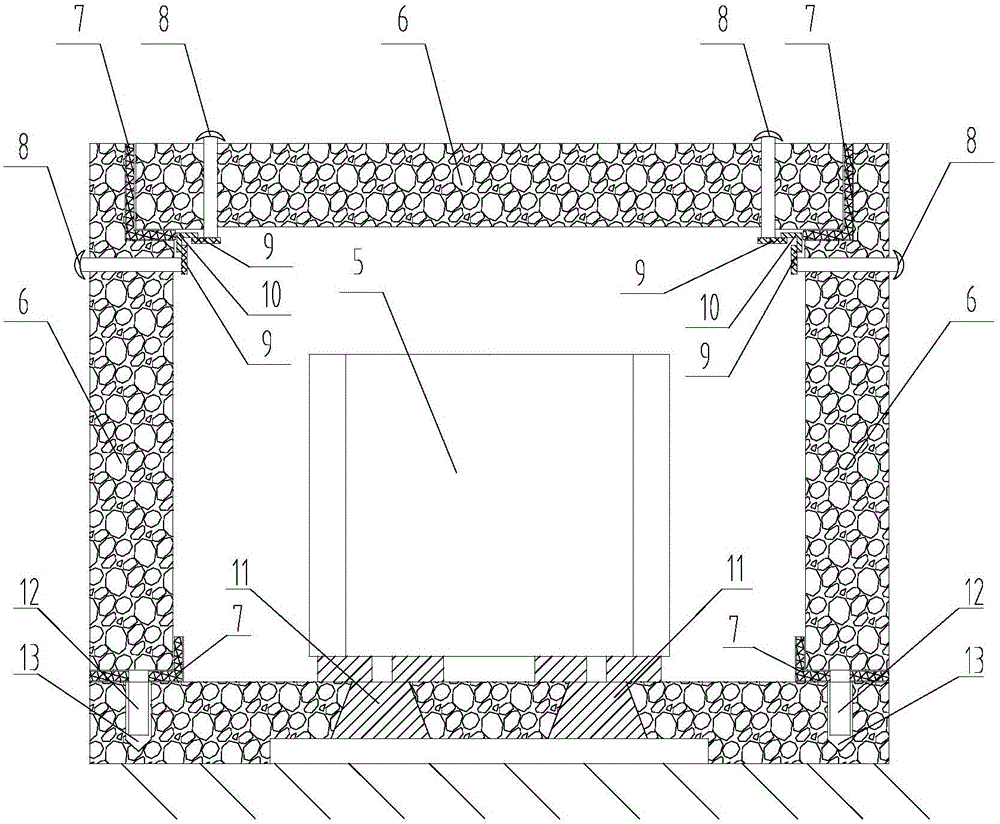

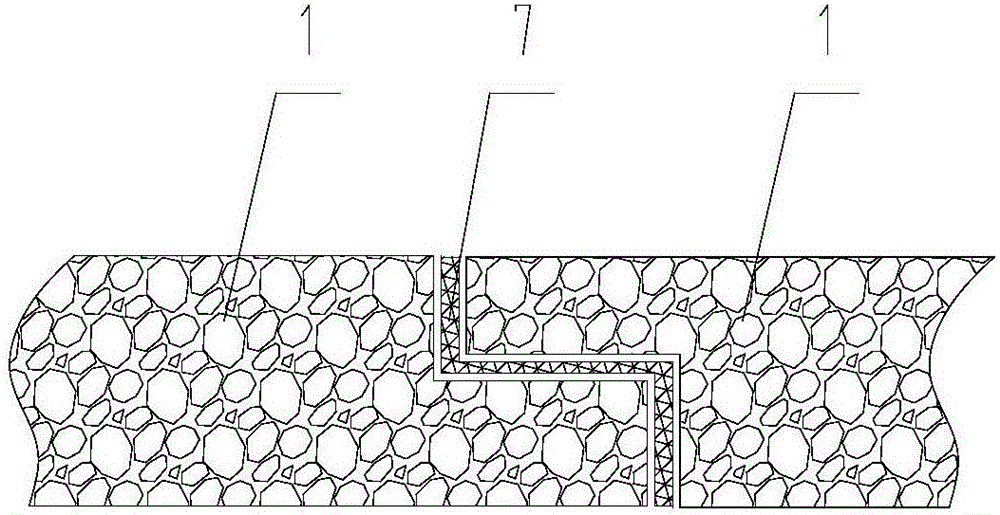

Composite noise reduction board and noise reduction device

A noise reduction board and noise reduction technology, applied in chemical instruments and methods, sound-producing instruments, instruments, etc., can solve the problems of high cost, high cost, and many consumables, and achieve the effect of effective sound absorption and noise reduction treatment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] Embodiments of the present invention will be further described in detail below in conjunction with the accompanying drawings and examples. The detailed description and accompanying drawings of the following embodiments are used to illustrate the principles of the present invention, but are not used to limit the scope of the present invention, that is, the present invention is not limited to the described preferred embodiments, and the scope of the present invention is defined by the claims .

[0028] Sound originates from the vibration of an object, which causes the vibration of the adjacent air to form sound waves, and propagates around in the air medium. When the sound is transmitted to the surface of the component material, part of the sound energy is reflected, part of the sound energy penetrates the material, and part of the sound energy is converted into heat energy due to the vibration of the component material or the friction with the surrounding medium when the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com