Powder dynamic sterilizing cooling cabinet

A cooling cabinet and dynamic technology, applied in the field of sterilization cabinets, can solve problems such as low work efficiency, low production efficiency, and affecting product quality, and achieve the effects of improving use safety, high production efficiency, and good sterilization effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

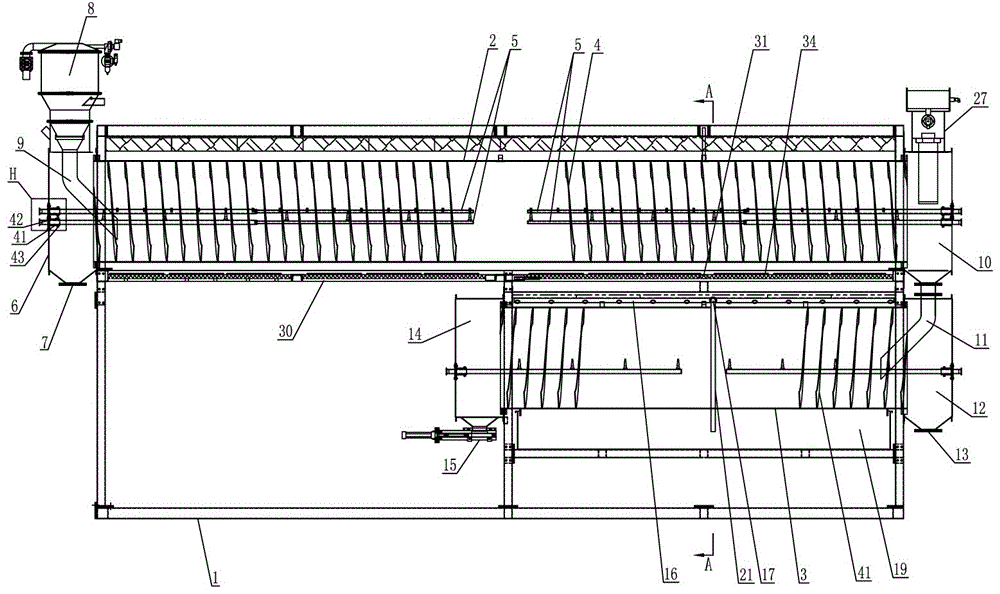

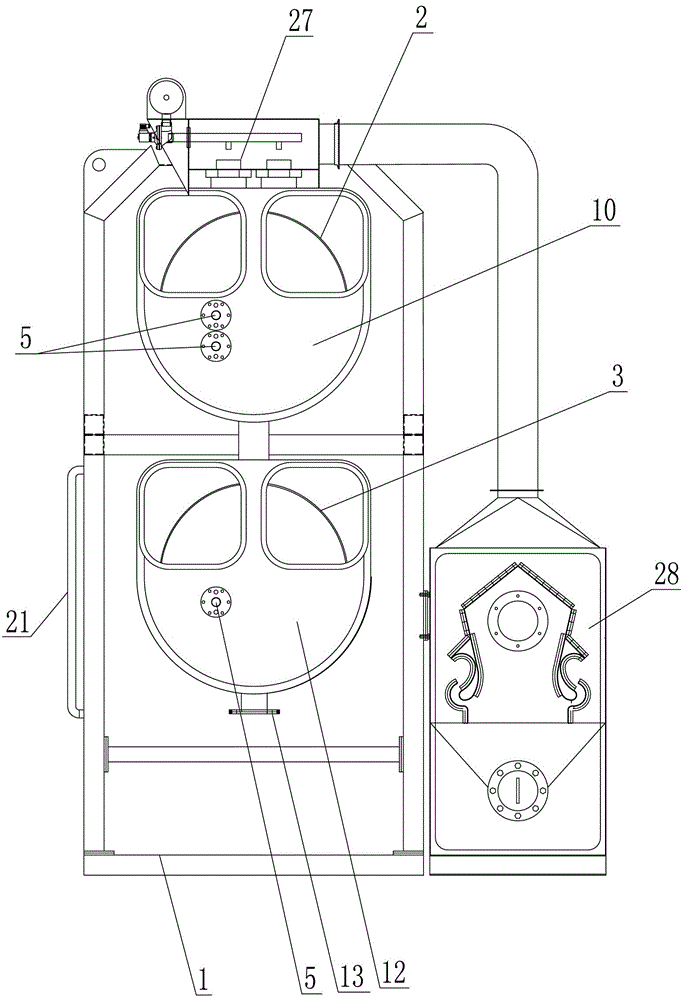

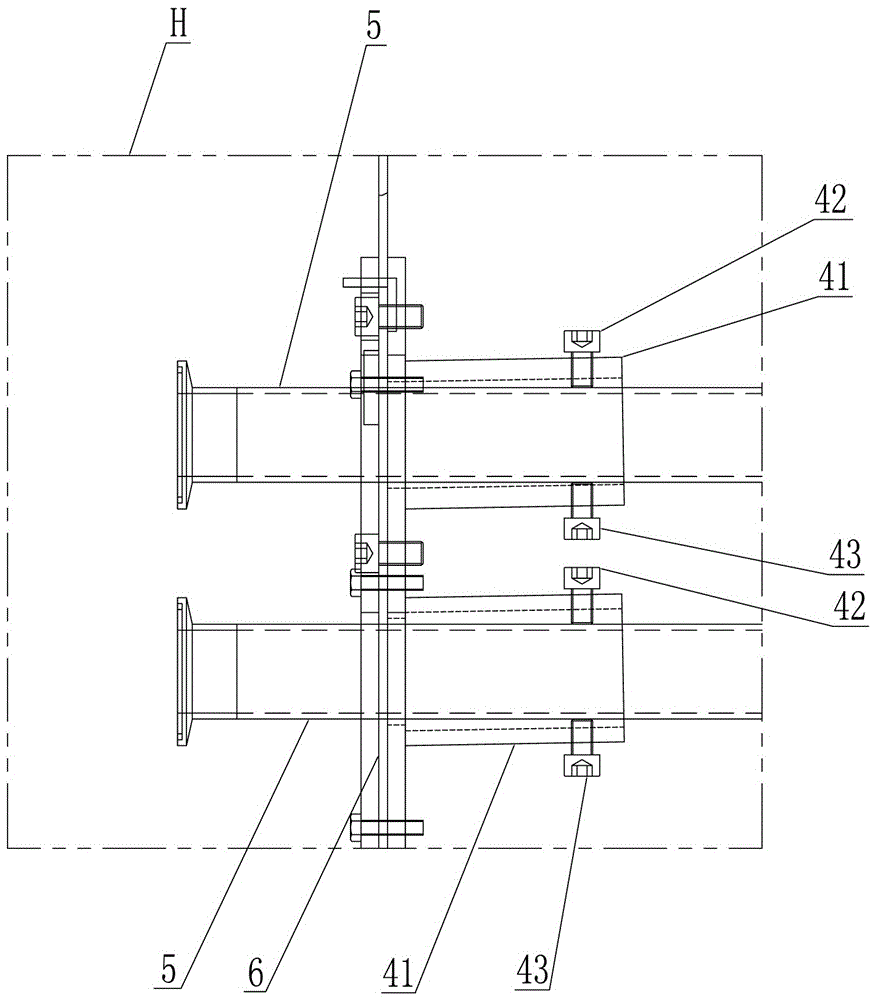

[0022] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Image 6As shown, the powder dynamic sterilization cooling cabinet includes: a frame 1, in which a sterilizing cylinder 2 and a cooling cylinder 3 distributed in parallel up and down are movably supported, and between the sterilizing cylinder 2 and Both ends of the cooling cylinder 3 are respectively provided with a feed inlet and a discharge outlet. On the inner wall of the sterilization cylinder 2, a spiral guide groove 4 is arranged in the axial direction, and on the inner wall of the cooling cylinder 3 A spiral material guide groove 41 is provided to the direction, and the sterilizing cylinder 2 and the cooling cylinder 3 rotate around their own central axes under the drive of the driving mechanism, so that the materials in each cylinder can be guided along their ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com