Hollow mandrel whole sand core casting mold for super long hollow camshaft

A technology of casting molds and camshafts, which is applied in the direction of manufacturing tools, casting molding equipment, casting molds, etc., can solve the problems of low strength and rigidity, long length, sand inclusion defects in hollow mandrels, etc., to ensure strength and rigidity, and facilitate Exhaust effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

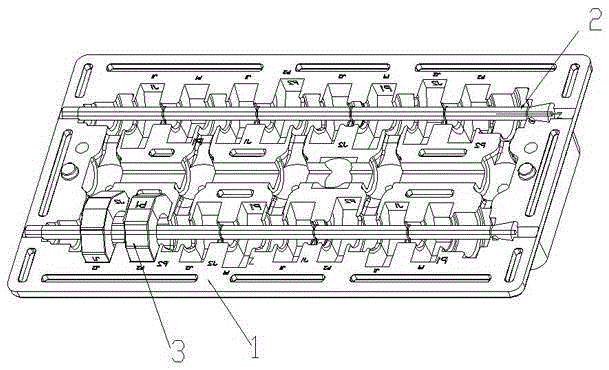

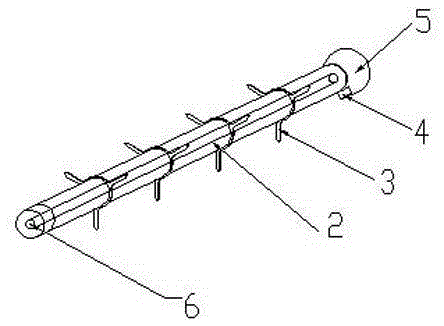

[0011] combine figure 1 , figure 2 As shown, the present invention is further described as follows: the hollow mandrel integral sand core casting mold of the super-long hollow camshaft includes an upper mold (not expressed in the figure), a lower mold 1, a resin sand integral sand core 2, a cold iron 3, and an upper mold. The cavity of the mold and the cavity of the lower mold 1 form the cavity of the hollow mandrel. The resin sand integral sand core 2 is placed in the lower mold, the cold iron 3 is set at the cam position of the hollow mandrel cavity, and the resin sand integral sand core 2 is placed at one end There are axially positioned core heads 5 and radially positioned core heads 4, and the integral resin sand core 2 is provided with a central air vent 6, and the integral resin sand core 2 is provided with four core supports at certain intervals along the length direction. 3. The core support is made of No. 45 nickel-plated steel. The core support protrudes three sup...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com