High-throughput preparation device and method applicable to duoka materials

A preparation device and high-throughput technology, applied in lighting and heating equipment, furnaces, furnace components, etc., can solve the problems of lack of batching system and high-throughput batching, and achieve the effect of simplifying the development process and reducing development costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

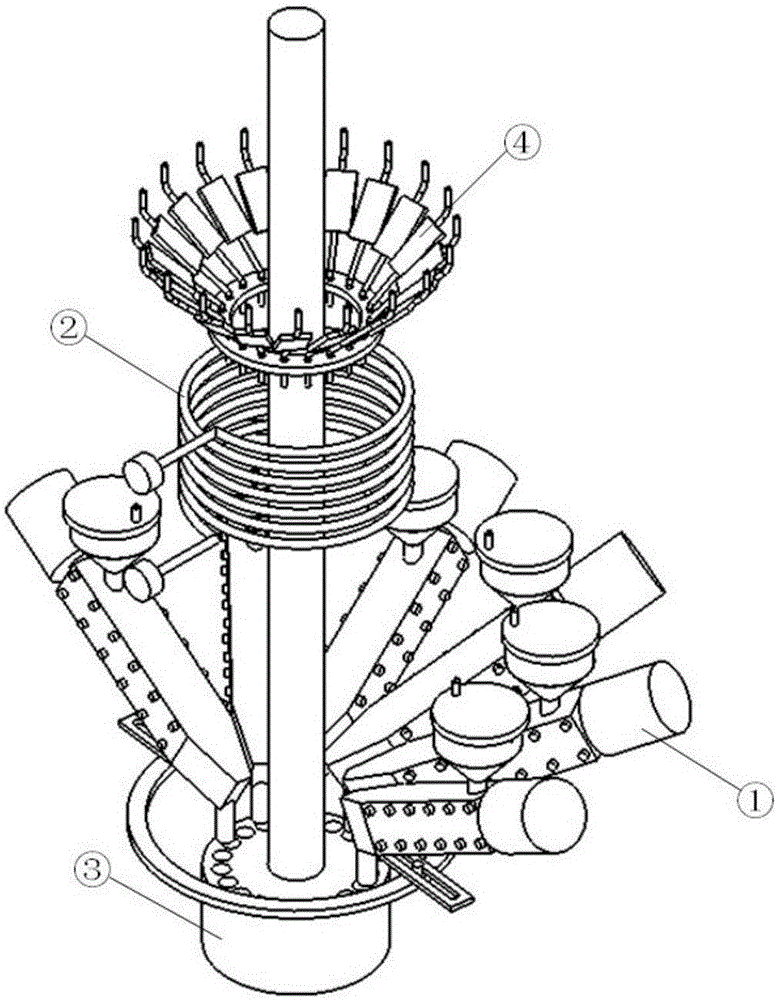

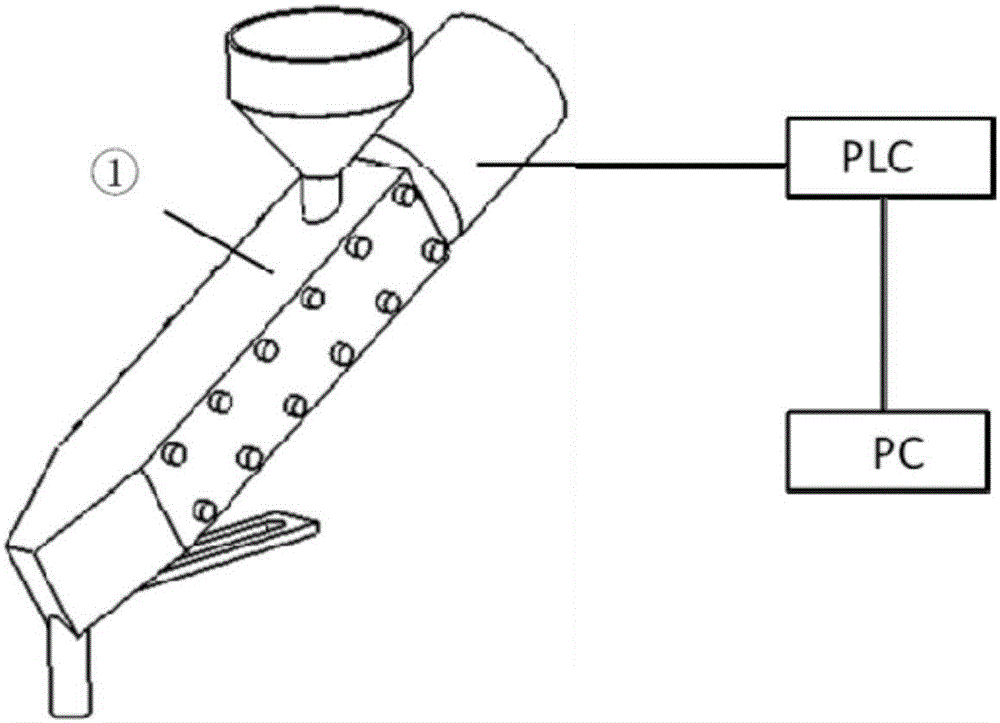

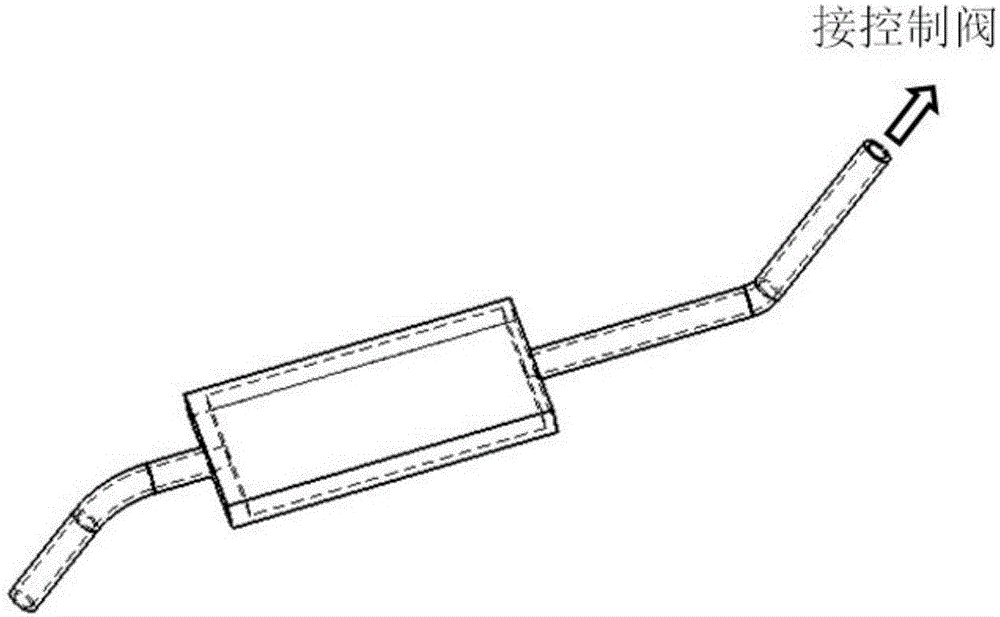

[0033] Such as figure 1 As shown, the high-throughput preparation device suitable for Doka materials in this embodiment includes integrated computer-controlled multi-component screw feeder, centralized induction melting, array crucible matrix and multi-cooling rate array suction casting system and its subsidiary systems. The screw feeder, induction melting and suction casting system described therein are arranged from top to bottom, and can also be arranged horizontally or in other ways as required. If the screw feeder, induction melting and suction casting system are arranged up and down, the array crucible matrix is movable up and down.

[0034] Taking La1+x Fe13Siy (x=0-1.2, y=1.1-1.8) as an example, replace the required La, Fe, and Si atomic ratios with volume fractions, and input the volume composition range of each element into the batching computer. The computer automatically calculates the volume of alloying elements required for each sample, and sends the informat...

Embodiment 2

[0040] Such as figure 1 As shown, the high-throughput preparation device suitable for Doka materials in this embodiment, wherein the induction melting is an upper and lower multi-layer induction melting system (such as Figure 4 Right), the suction casting system has two sets of corresponding suction casting molds and corresponding suction casting nozzles.

[0041] Taking Ni100-x-y-zFexGayCoz, where 17≤x≤26, 25≤y≤28, 0≤z≤6 as an example, the required atomic ratio of Ni, Fe, Ga, Co is replaced by volume fraction, and the volume of each The volume composition range of elements is input into the batching computer, and the computer automatically calculates the volume of alloying elements required for each sample, and sends the information to the designated screw feeder.

[0042] Add Ni, Fe, Ga, and Co alloy pellets to the four screw feeders respectively. According to the volume given by the batching computer, the screw feeder is automatically advanced to push the required volume o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com