A multifunctional and highly wear-resistant intelligent metal sheet trimming machine

A metal sheet, high wear-resistant technology, applied in machine tools, grinding slides, grinding frames, etc. suitable for grinding the edge of workpieces, can solve problems such as damage to workers' health, improve service life, wide processing range, The effect of reducing the braking load of the motor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

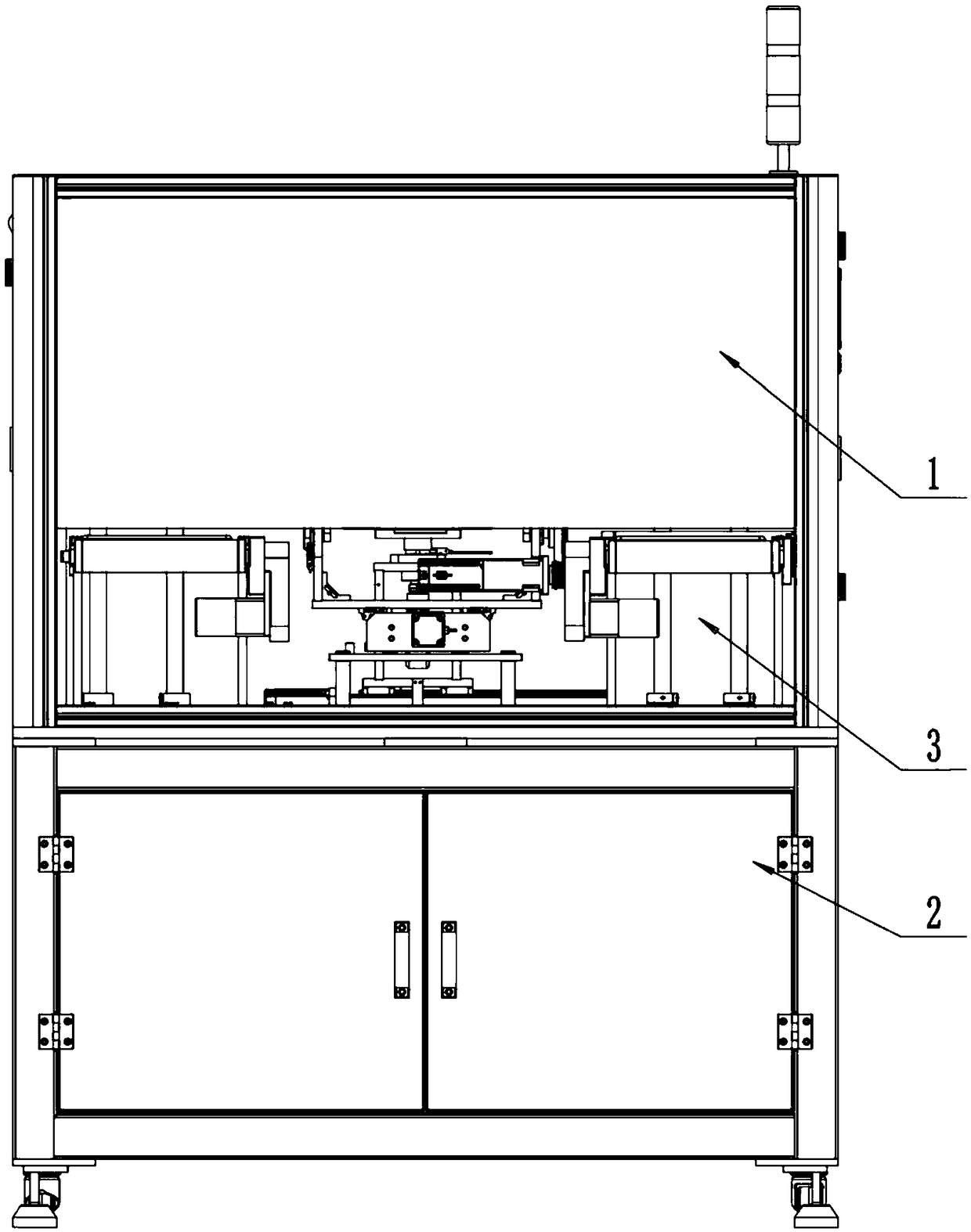

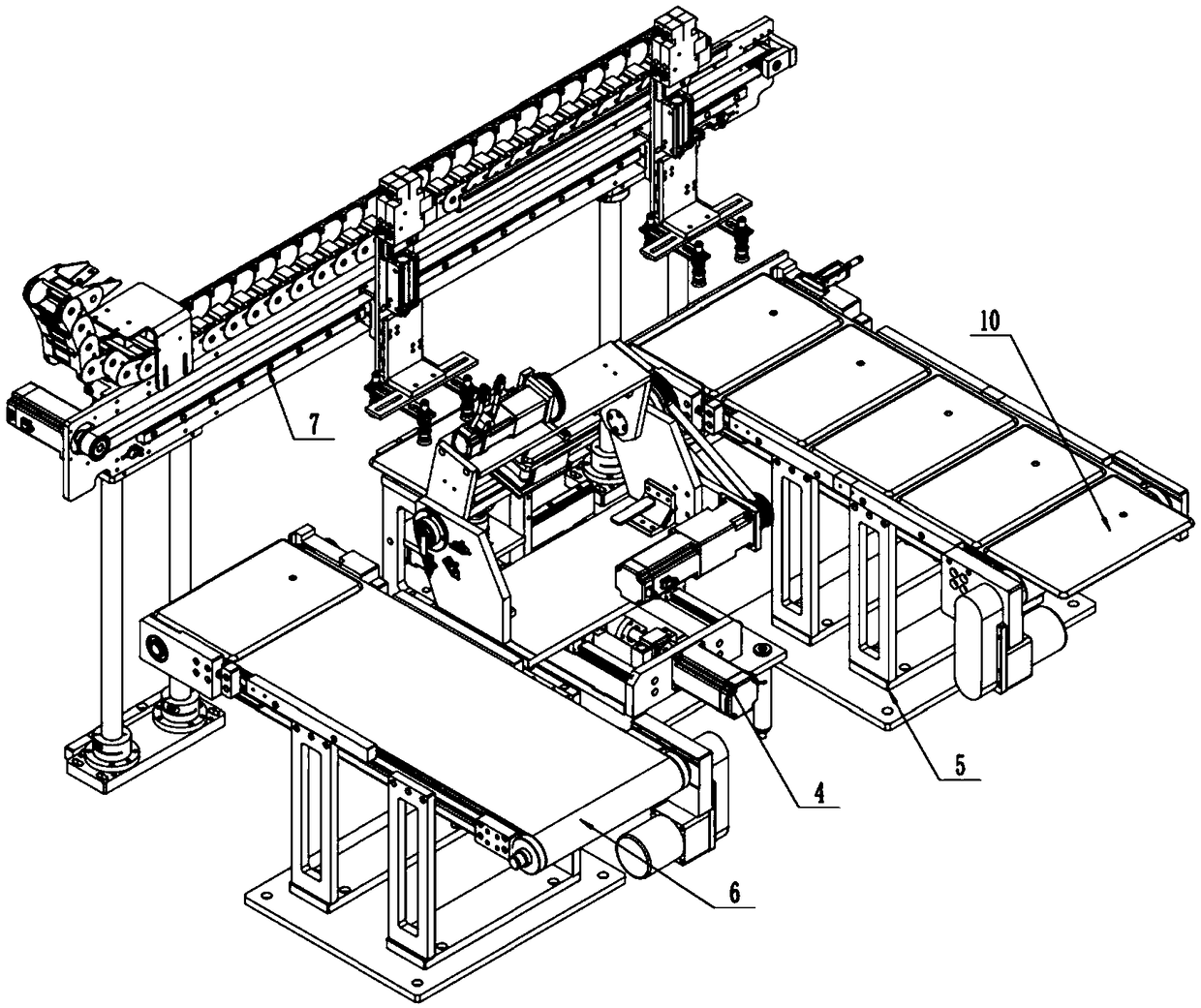

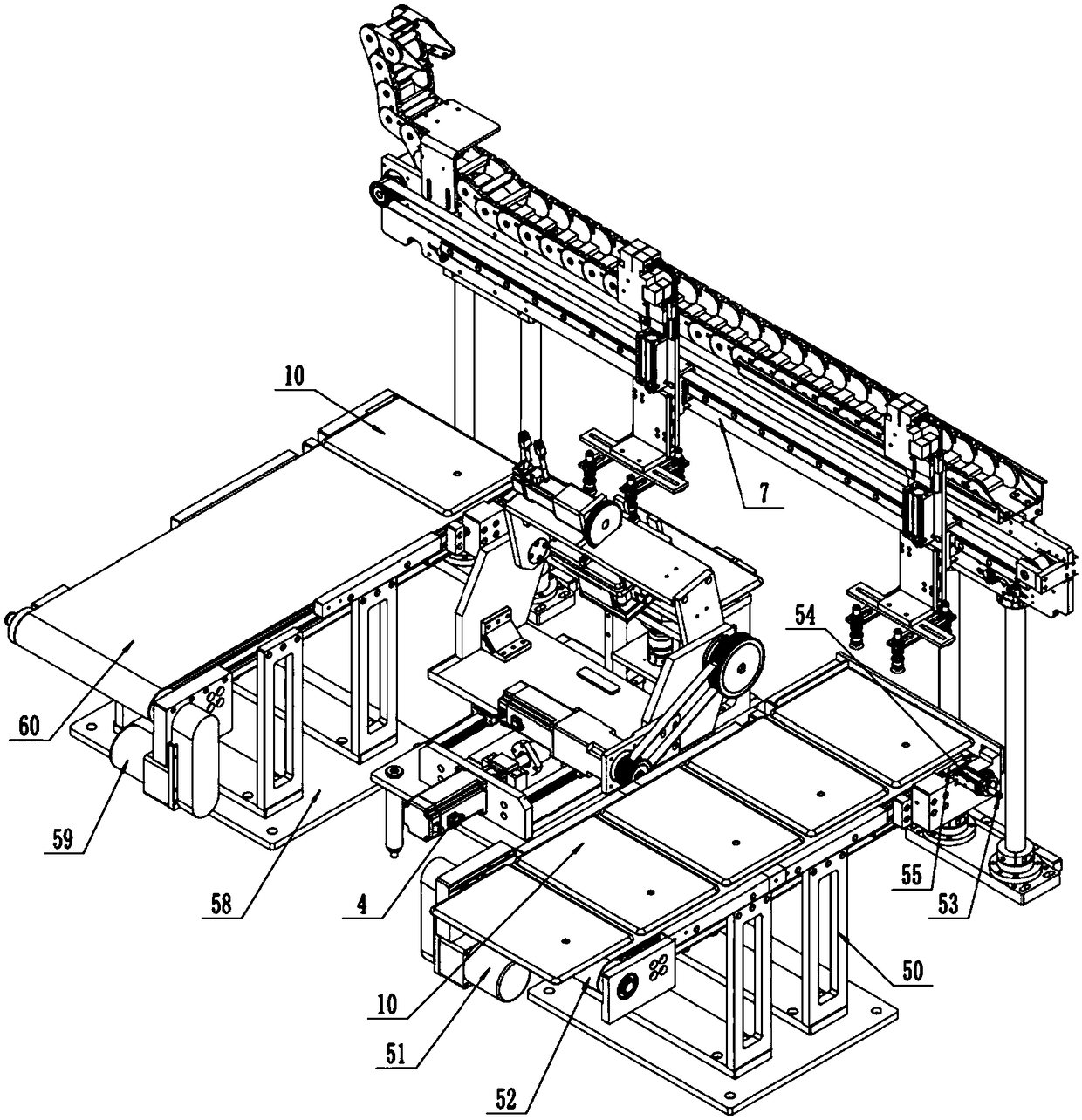

[0047] refer to Figure 1-13 , specifically as Figure 1-3 As shown, the multifunctional and highly wear-resistant intelligent metal sheet trimming machine of the present invention includes a frame assembly 2, a high wear-resistant processing device 3 that is arranged on the frame assembly 2 and strengthened by a surface ion plating coating and The transparent protective cover body 1 covered on the high wear-resistant processing device 3; the high wear-resistant processing device 3 includes the trimming center 4, the feeding device 5, the unloading device 6 and the manipulator device 7; the opening and closing of the transparent protective cover body 1 The door is set on the front of the high wear-resistant trimming center 4, and a channel passing through the metal plate 10 to be processed is provided between the bottom of the opening and closing door and the upper end of the frame assembly 2, and the channel is connected to the beginning of the feeding device 5 and the feedin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com