Novel numerical control woodwork processing equipment

A processing equipment and woodworking technology, which is applied in the field of new CNC woodworking processing equipment, can solve the problems of complex lifting components and large space occupation, and achieve the effect of simple transmission mode, easy operation, and reduced equipment volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] Below in conjunction with accompanying drawing and embodiment the present invention is further described:

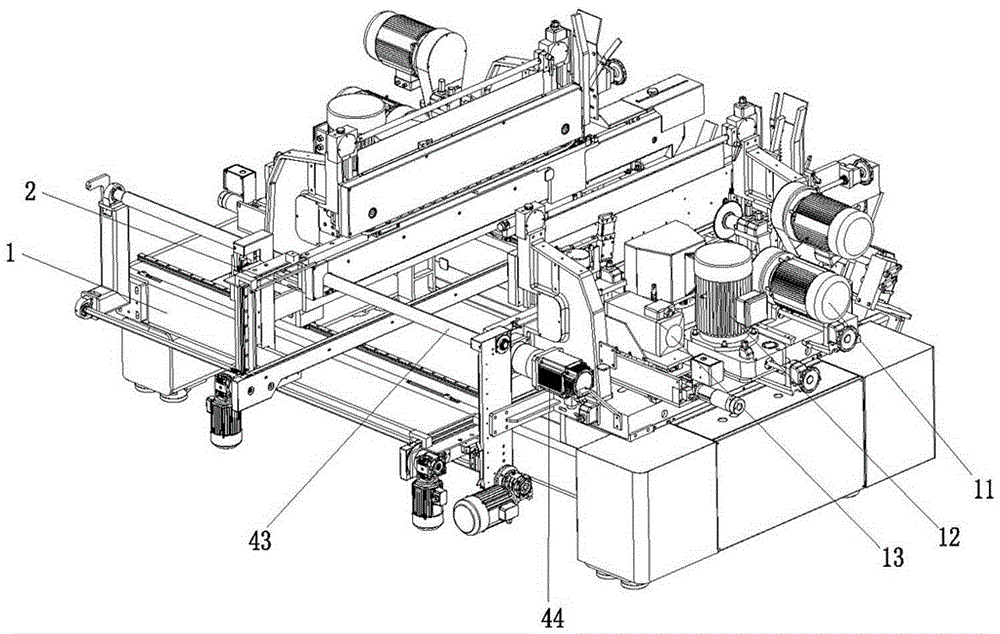

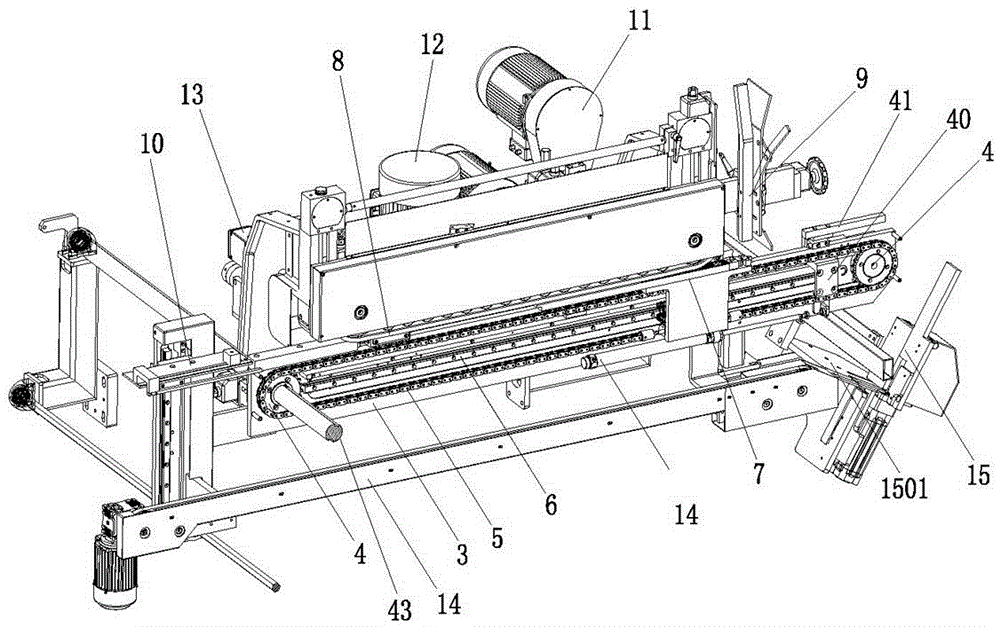

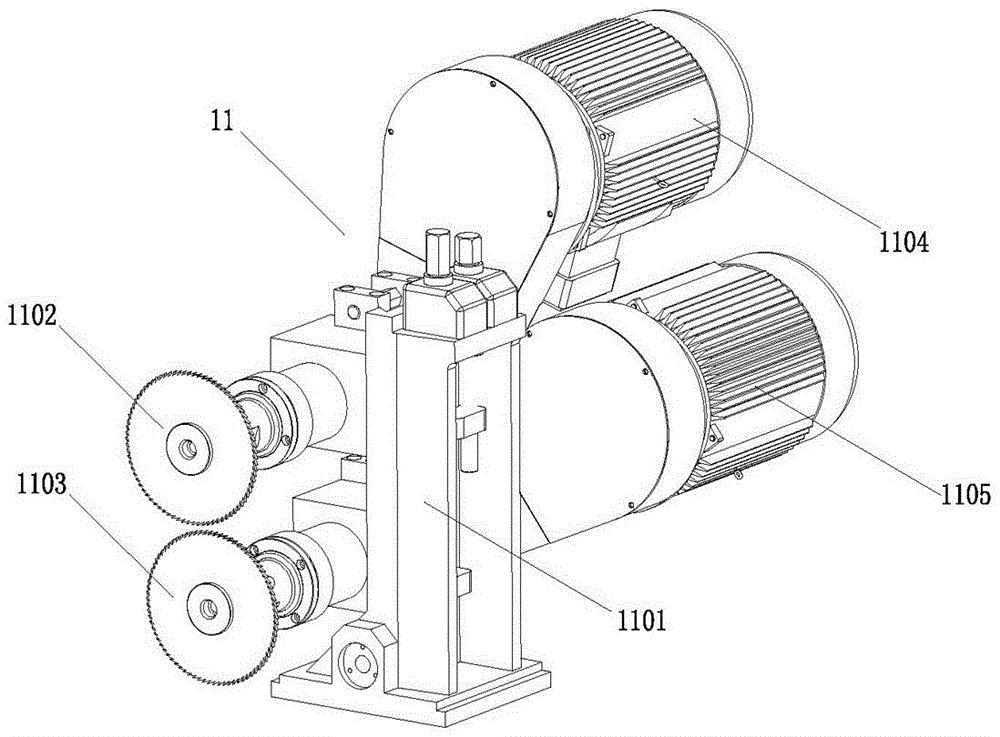

[0045] Such as Figure 1 to Figure 4 As shown, the new CNC woodworking processing equipment includes a frame 1, and a feeding and discharging integrated mechanism 2 is installed on the frame 1;

[0046] The feeding and discharging integrated mechanism 2 includes two feeding fixing plates 3 arranged on both sides of the frame 1. The feeding fixing plates 3 on each side are connected with the feeding chain 5 through the sprockets 4 at both ends, and the feeding fixing plates 3 are fixed with feeding chains. Guide rail 6, on the feeding guide rail 6, the feeding rack 7 that is connected with the feeding chain 5 is slidably installed, and the top of the feeding rack 7 is provided with a pressing conveyor belt 8, and one end of the pressing conveyor belt 8 is equipped with a storage material for storing workpieces 51 Frame 9, the other end of pressing conveyor belt 8 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com