3D building printing head and mobile 3D building printing device thereof

A printing device and print head technology, which is applied in the direction of manipulators, ceramic molding machines, manufacturing tools, etc., can solve the problems of printing, assembly, transportation and other links, increase production costs and cycles, and complex installation and debugging technology, etc., to shorten production cycle, improve equipment stability, and improve printing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

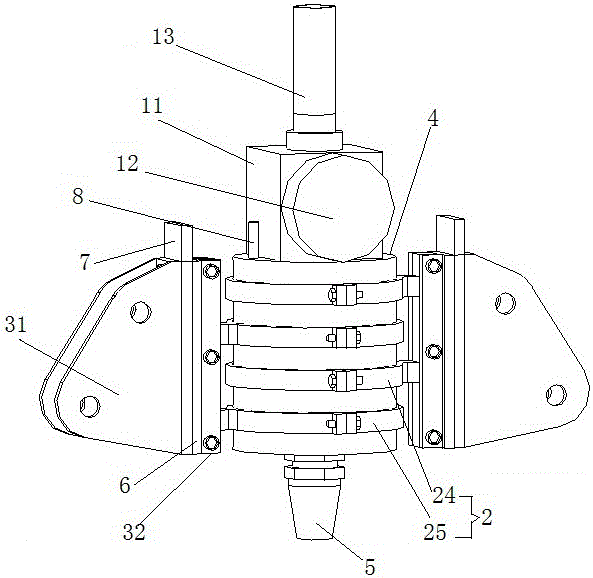

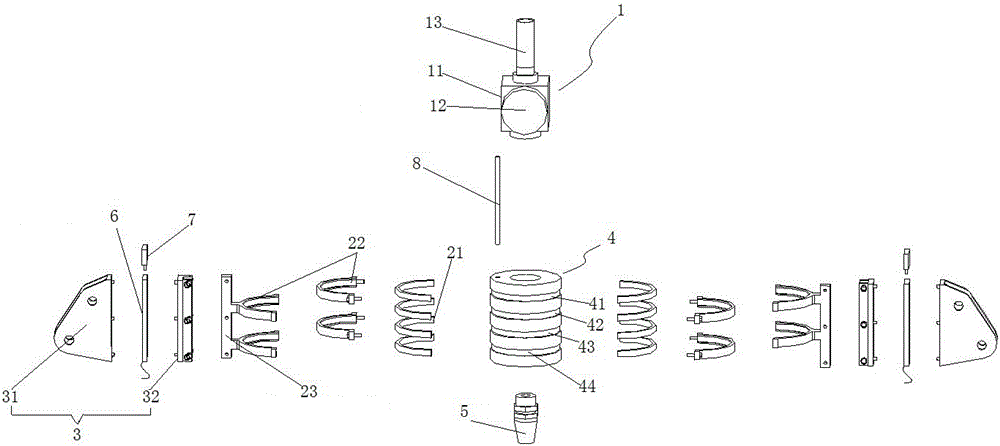

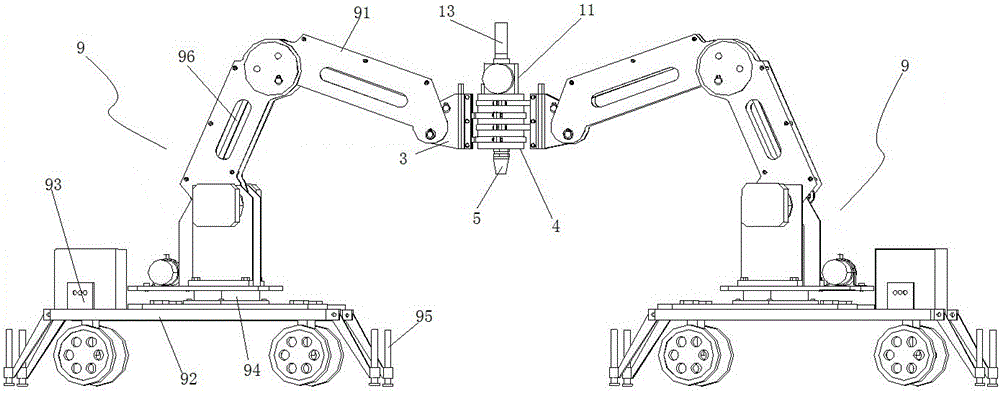

[0035] Such as Figure 1~2 Shown, a kind of 3D construction printing head, comprises hollow printing head body 4, is installed on the top of printing head body 4 and can feed material into the hollow cavity of printing head body 4 feeding device 1, is installed in printing head body 4 the nozzle 5 at the bottom and docked with the hollow cavity of the print head body 4.

[0036] The outer wall of the print head body 4 is covered with at least two sets of bearing assemblies 2 arranged vertically and staggered. The outer wall of each bearing assembly 2 is correspondingly connected with a printing head connecting frame 3 for connecting with a printing device.

[0037] The bearing assembly 2 includes a bearing 21 and a bearing cap 22 tightly hooped on the bearing 21 , and the bearing cap 22 is fixedly connected to the print head connecting frame 3 through a bearing cap bracket 23 . On the outer wall of the print head body 4 there are grooves for fitting the bearings 21 at interv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com