Rubber grinding machine for improving grinding quality

A rubber grinding machine, high-quality technology, applied in the direction of mechanical material recovery, recycling technology, plastic recycling, etc., can solve the problems of uneven powder particle size, low rubber powder quality, low grinding efficiency, etc., to improve grinding quality, Avoid grinding disc aging and improve efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

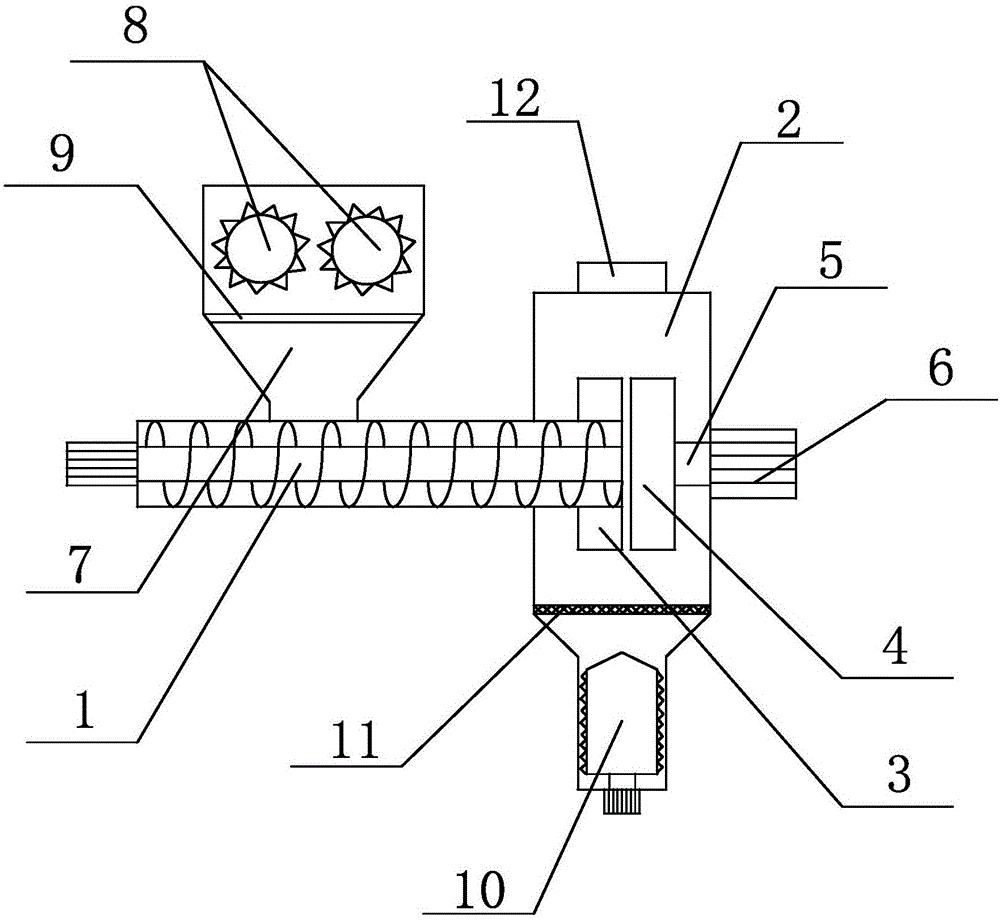

[0025] Such as figure 1 As shown, a rubber grinder capable of improving the grinding quality of the present invention includes a horizontally arranged feeding mechanism 1, the feeding mechanism 1 is connected to the grinding chamber 2, and the grinding chamber 2 is provided with a fixed grinding disc 3 and a moving grinding disc 4. There is an opening in the center of the grinding disc 3, the discharge end of the feeding mechanism 1 communicates with the opening on the fixed grinding disc 3, the moving grinding disc 4 is connected with the first motor 6 through the horizontal spindle 5; the feeding mechanism 1 includes a screw feeding tube and speed-regulating motor, a feeding hopper 7 is arranged on the screw feeding pipe, a crushing impeller group 8 is arranged above the feeding hopper 7, and a magnetic screen 9 is arranged between the crushing impeller group 8 and the feeding hopper 7 , the bottom of the fixed millstone 3 and the movable millstone 4 is provided with a verti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com