Discharge device of plastic bag folding machine

A technology of a discharge device and a folding device, which is applied to packaging and other directions, can solve the problems of difficulty in folding, chaotic plastic bags, and large elasticity of plastic bags, and achieves the effect of simple structure and improved qualification rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

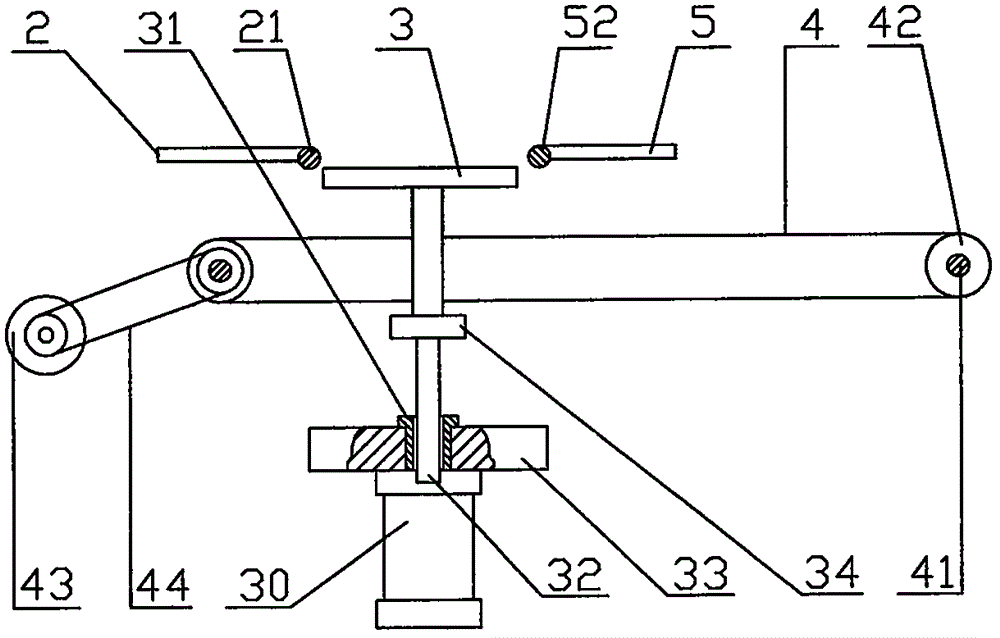

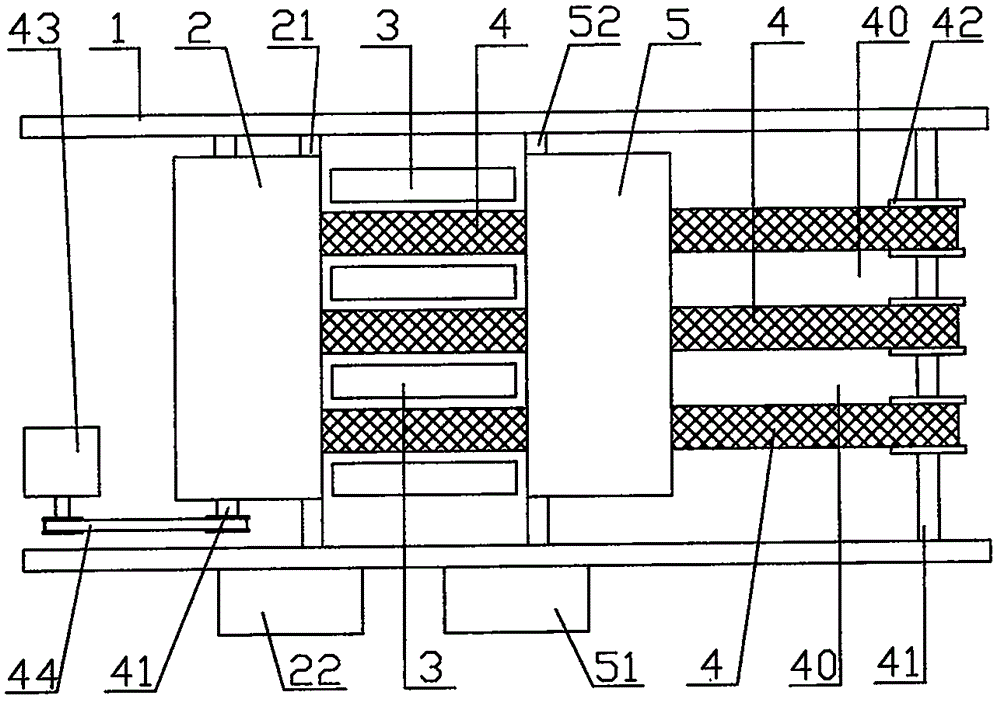

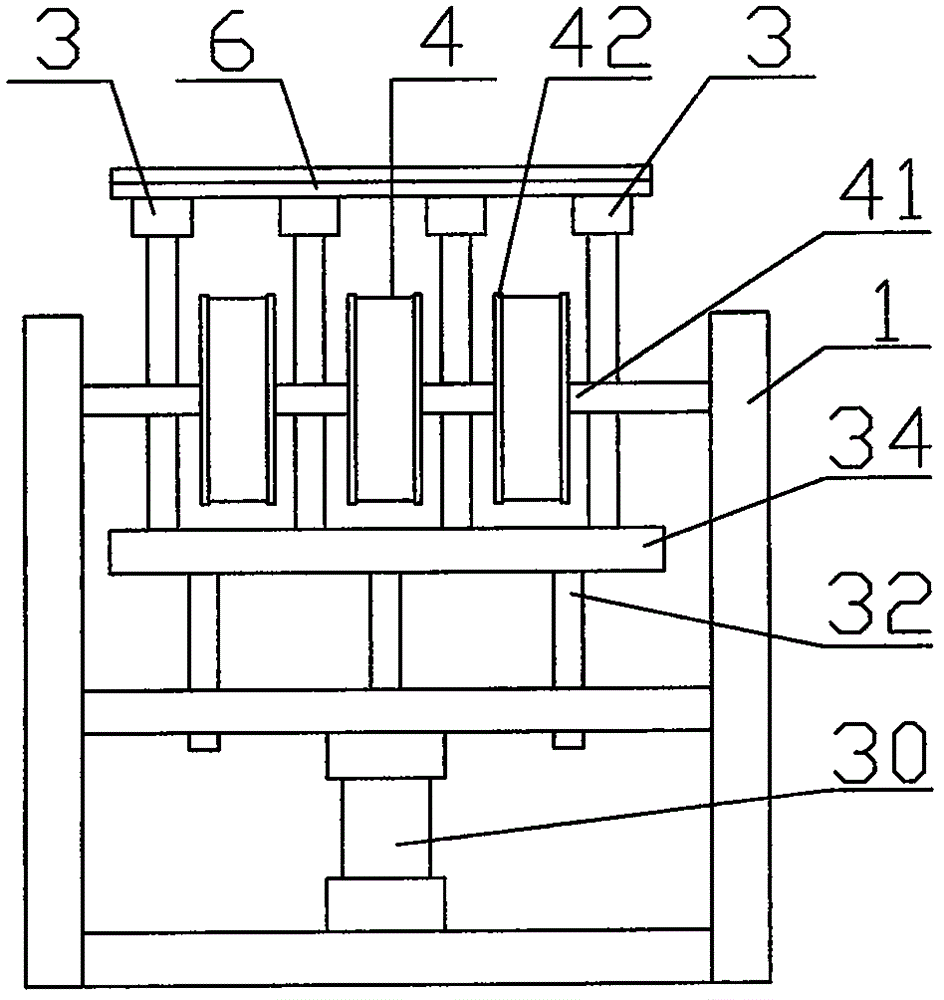

[0028] Embodiment one, such as figure 1 , figure 2 As shown, the left side in the accompanying drawings is the front described in this specification, and the right side of the figure is the back. Install the first folding rotating shaft 21 on both sides of the front of the frame 1, connect the swing cylinder 22 at one end of the first folding, install the handle folding device at the middle position and the front position of the first folding rotating shaft 21, and install it behind the first rotating shaft Tail folding rotating shaft 52, one end of tail folding rotating shaft 52 is connected swing cylinder 51, and tail folding device is installed in the middle section of tail rotating shaft 52 and its rear. In the technical background of this description, the handle folding device of the plastic bag folding machine and the tail folding device of the plastic bag folding machine have been given. The front folding device and the tail folding device. Two power transmission sh...

Embodiment 2

[0030] Embodiment 2, the difference between embodiment 2 and embodiment 1 is: the described elevating mechanism is a kind of guide rod cylinder 7, and a guide rod cylinder is respectively installed on the frame below the gap 40 of each conveyer belt 7. The folding platform 3 is respectively installed on the cylinder rod seat 71 of the guide rod cylinder 7, and the air ducts for multiple guide rod cylinders 7 are connected and controlled by the same solenoid valve. The feature of this embodiment is that the platform support can be omitted.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com