Antistatic bag

An anti-static bag and bag body technology, applied in the field of packaging, can solve the problems of uneven folding, inability to shape, dust pollution of electronic products, etc., and achieve the effect of simple production and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

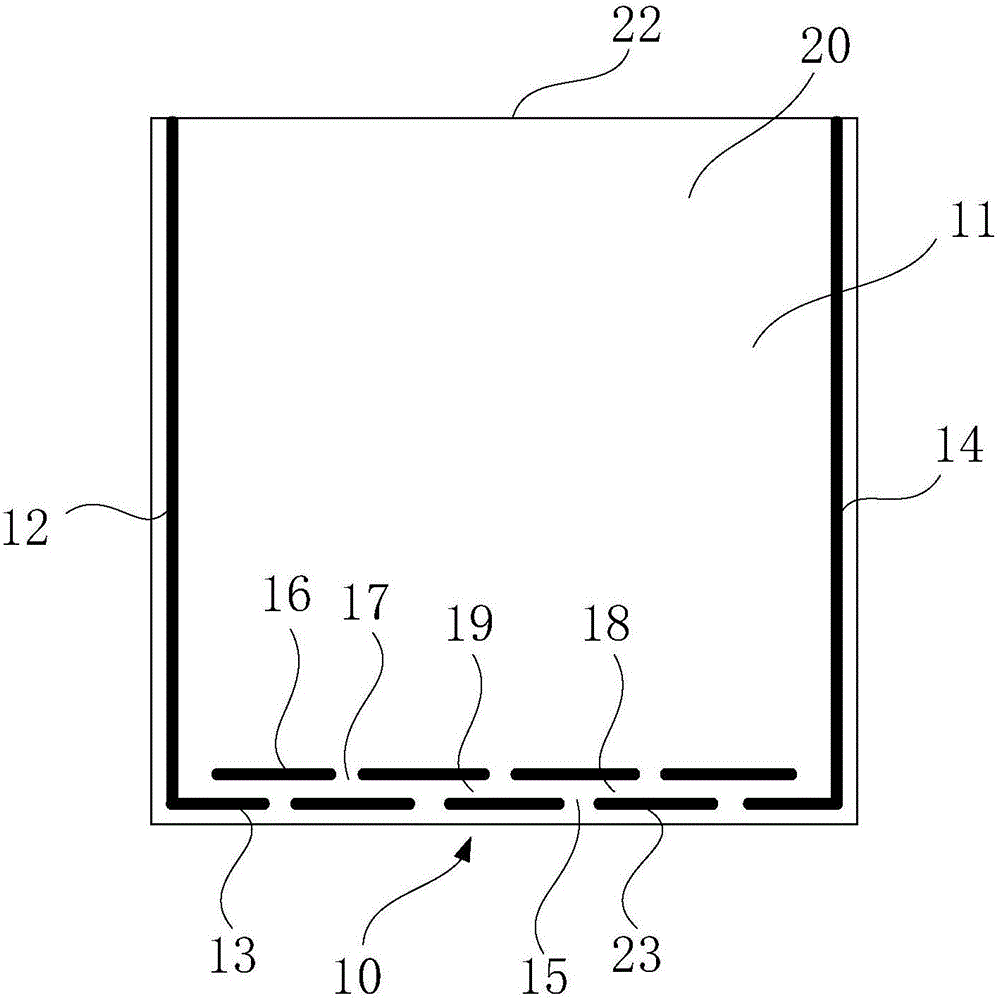

[0020] With the development of science and technology, electronic products are increasingly miniaturized, and high-density integrated circuits have become an indispensable device in the electronic industry. Electronic products with the characteristics of line spacing, thin lines, high integration, low power and high input impedance are very sensitive to static electricity. Electrostatic discharge is one of the main causes of component breakdown hazards and operational disturbances. Using the antistatic bag 10 provided by the present invention to load electronic products can prevent electronic products from accumulating static electricity during transportation and storage.

[0021] The present invention will be further described below in conjunction with accompanying drawing.

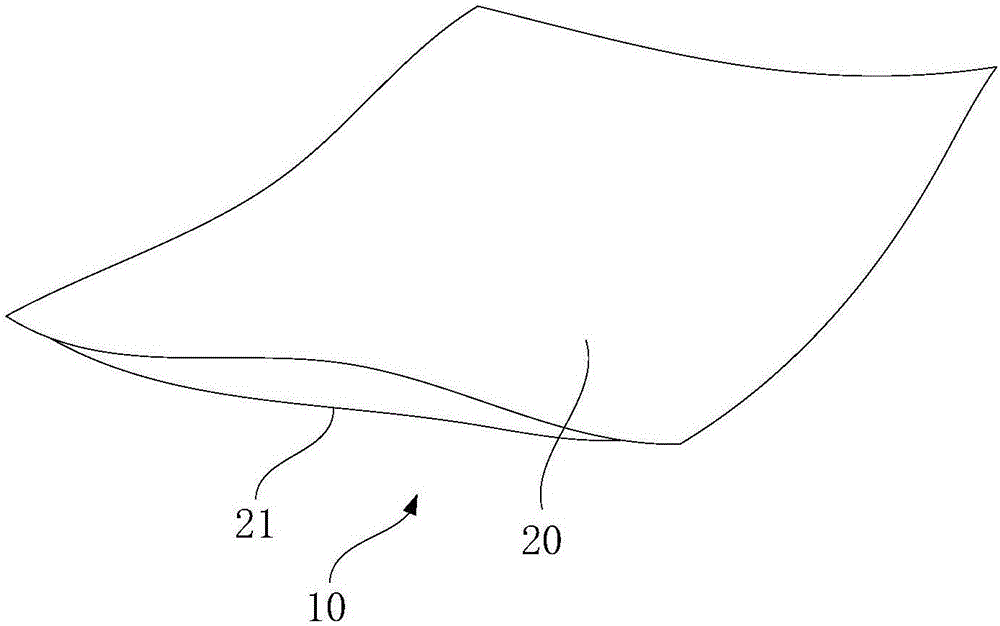

[0022] like figure 2 and image 3 As shown, the antistatic bag 10 includes a bag body 11 , a first heat-sealing strip 12 , a second heat-sealing strip 13 and a third heat-sealing strip 14 . The firs...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com