Anti-freezing concrete using steam-curing technology

A concrete and process technology, applied in the field of concrete, can solve the problems of support and inapplicability, and achieve the effects of low production cost, improved product speed, and high freeze-thaw resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

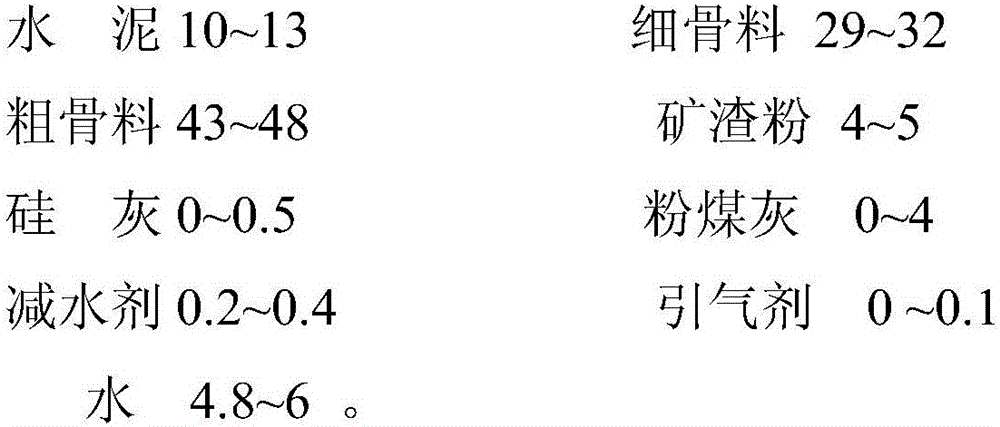

[0019] An optimal component of frost-resistant concrete that adopts steam-cured technology, according to the weight of kg per part,

[0020] Cement 10.20kg Fine aggregate 31.11kg Coarse aggregate 46.29kg

[0021] Slag powder 4.26kg Silica fume 0.42kg Fly ash 2.53kg

[0022] Water reducing agent 0.24kg Air-entraining agent 0.03kg Water 4.93kg.

Embodiment 2

[0024] A component of frost-resistant concrete that adopts the steam-curing process, according to the weight of each part, kg,

[0025] Cement 10kg Fine aggregate 29kg Coarse aggregate 43kg

[0026] Slag powder 4.0kg Silica fume 0.3kg Water reducer 0.2kg

[0027] Air-entraining agent 0.03kg water 6kg.

Embodiment 3

[0029] A component of frost-resistant concrete that adopts the steam-curing process, according to the weight of each part, kg,

[0030] Cement 13kg Fine aggregate 32kg Coarse aggregate 48kg

[0031] Slag powder 5kg Water reducing agent 0.2kg Air entraining agent 0.1kg

[0032] 4.8kg of water.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| slump | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com