Ceramic firing method

A technology of ceramics and ceramic blanks, which is applied in the field of ceramic manufacturing, can solve problems such as poor load-bearing capacity, low mud plate strength, deformation, etc., and achieve the effects of improving firing pass rate, solving deformation problems, and reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] A ceramic firing method, comprising:

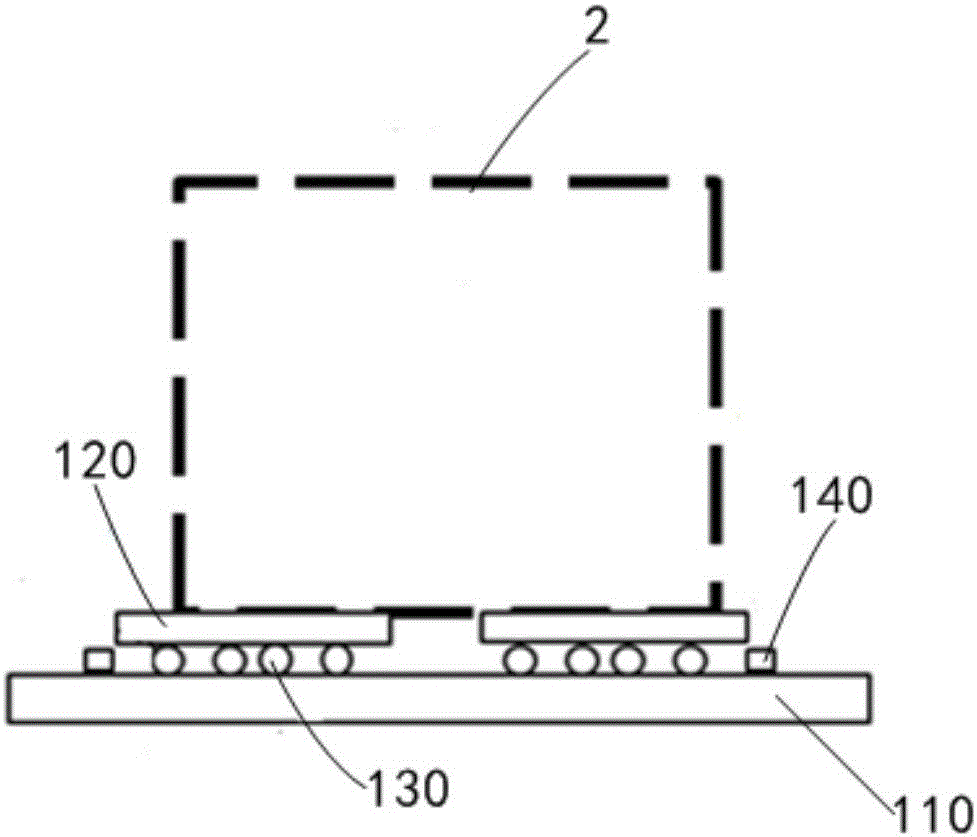

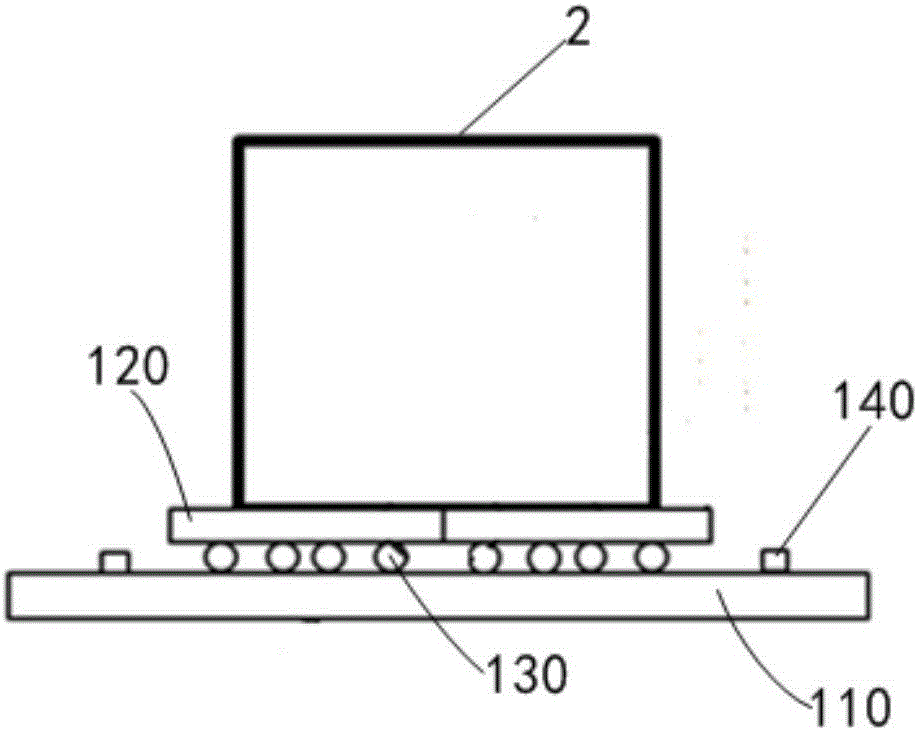

[0046] 1. Install the first kiln panel 110 horizontally in the kiln.

[0047] 2. A plurality of high temperature resistant ceramic balls 130 are laid on the first kiln plate 110 .

[0048] 3. Lay two second kiln panels 120 on a plurality of high-temperature-resistant ceramic balls 130, and the gap between adjacent second kiln panels is 35 mm.

[0049] 3. Place the ceramic green body 2 on the second kiln board 120 so that the bottom is evenly supported by the two second kiln boards 120 .

[0050] 4. On the first kiln plate 110, a stop frame 140 for limiting the position outside the high-temperature-resistant ceramic ball 130 is provided, and its thickness is 15 mm.

[0051] 5. Start the kiln to fire the ceramic green body 2 at a firing temperature of 1300° C. for 8 hours.

[0052] The ceramic green body fired in this embodiment is in the shape of a pair of long strips, and the shrinkage of the narrower side can be ignored, so two...

Embodiment 2

[0054] A ceramic firing method, comprising:

[0055] 1. Install the first kiln panel 110 horizontally in the kiln.

[0056] 2. Lay a plurality of high temperature resistant alumina balls 130 on the first kiln plate 110 .

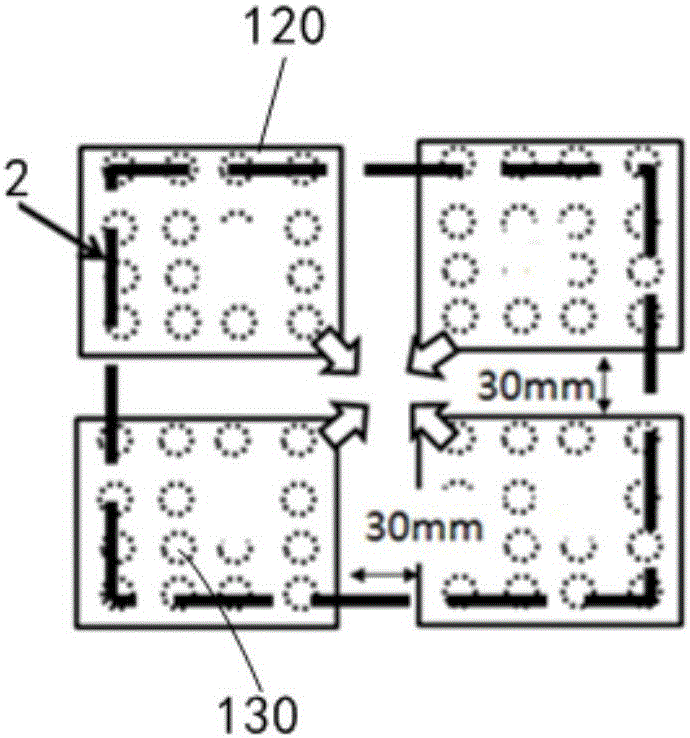

[0057] 3. Lay four second kiln panels 120 in a 2×2 matrix on multiple high-temperature-resistant alumina balls 130, and the gap between adjacent second kiln panels is 30mm.

[0058] 3. Place the ceramic green body 2 on the second kiln board 120 so that the bottom thereof is evenly supported by four second kiln boards 120 .

[0059] 4. On the first kiln plate 110, a stop frame 140 for limiting the position outside the high-temperature-resistant alumina ball 130 is provided, and its thickness is 16mm.

[0060] 5. Start the kiln to fire the ceramic green body 2 at a firing temperature of 1200° C. for 7 hours.

[0061] The ceramic body fired in this embodiment has a regular shape with almost the same length and width, so four second kiln plates 120 are select...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com