Metal hybridized fluorine-silicon ultra-light mold releasing agent and preparation method thereof

A light-release, hybrid technology, applied in adhesives, coatings, etc., can solve the problems of poor bonding force and heat resistance between fluorosilicone release agent and substrate surface, release force and residual adhesion need to be improved, etc. , to achieve the effect of improving bonding force, increasing residual adhesion, and improving heat resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

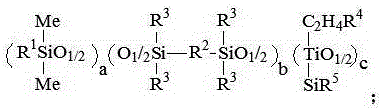

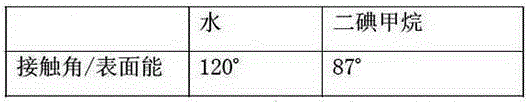

[0020] The structural formula of metal hybrid fluorosilicone oil is as follows:

[0021]

[0022] Among them, a / b / c=1 / 4 / 4, the weight average molecular weight is above 9000, each component is weighed according to the weight ratio; 100 parts of metal hybrid fluorosilicon silicone oil, 1 part of hydrogen-containing silicone oil (hydrogen content 1.6% ), 6 parts of vinyl MQ silicone resin were dissolved in 2000 parts of 1,3-bistrifluoromethylbenzene, after stirring evenly, 200ppm of platinum catalyst was added, and coated on the non-corona PET film, at 150 o After baking at C for 35s, the fluorine release film was obtained. The test results are as follows:

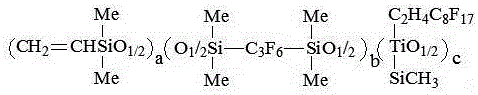

[0023] Table 1: Contact Angle and Surface Energy Tests

[0024]

[0025] Table 2: Release performance and heat resistance test

[0026]

Embodiment 2

[0028] The structural formula of metal hybrid fluorosilicone oil is as follows:

[0029]

[0030] Where a / b / c=3 / 2 / 4, the weight average molecular weight is above 16000, weigh each component according to the weight ratio; 100 parts of metal hybrid fluorosilicone silicone oil, 10 parts of vinyl MQ silicone resin, 6 parts of A151 Dissolve vinyl silane coupling agent in 4000 parts of 1,3-bistrifluoromethylbenzene, stir evenly, add 100ppm of platinum catalyst and 50ppm of organotin catalyst, and coat on non-corona polyimide film , at 150 o After baking at C for 35s, the fluorine release film was obtained. The test results are as follows:

[0031] Table 1: Contact Angle and Surface Energy Tests

[0032]

[0033] Table 2: Release performance and heat resistance test

[0034]

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap