Bioreactor low-shearing lifting type ventilation stirring device

A bioreactor, aeration and stirring technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

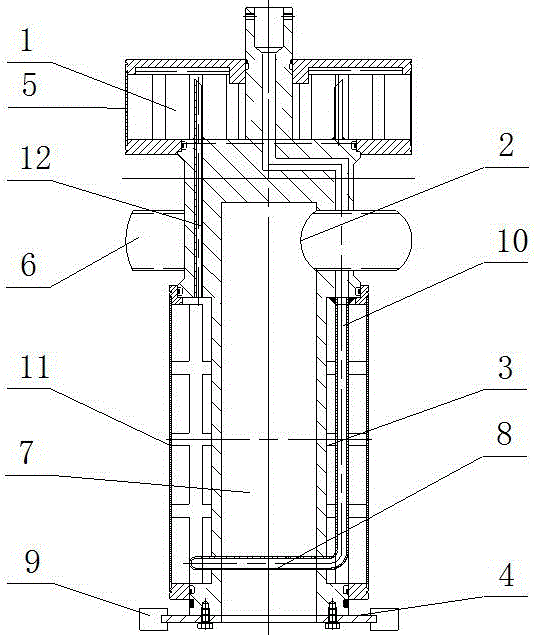

[0013] This embodiment is a bioreactor low-shear lifting type aeration stirring device, the structure is as follows figure 1 As shown, it includes a defoaming chamber 1, a negative pressure stirrer 2, a ventilating chamber 3 and a lower stirrer 4, and the defoaming chamber, negative pressure stirrer, ventilating chamber and the lower stirrer are sequentially arranged on the same axis from top to bottom, The defoaming section passes through the negative pressure stirring section through the foam overflow conduit 12 and communicates with the ventilating dispersion section. Three stirring tubes 6 are evenly arranged on the outside of the device, and the setting direction of the stirring tubes is perpendicular to the direction of the hollow shaft 7. The opening at the outer end of the stirring tubes is a slope structure, and the direction of the slope structure of the stirring tubes is set in the same direction, and the direction of the slope of the stirring tubes is consistent wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com