Site quick assembling and disassembling technology and matching device for railway track glued insulation joint

An insulating joint, on-site technology, applied in the field of installation device, heating and cooling device and disassembly, and auxiliary heating device, can solve the problems of long time for re-bonding and installation, difficult to meet the maintenance point of skylight, and inability to quickly solve the fault of connecting the insulation joint. , to achieve the effect of reducing material and labor costs and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0062] In order to better understand the present invention, the present invention will be further described below in conjunction with the accompanying drawings and embodiments.

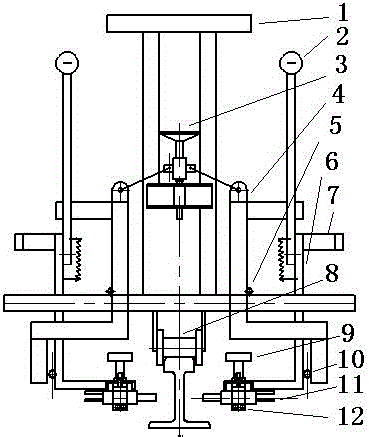

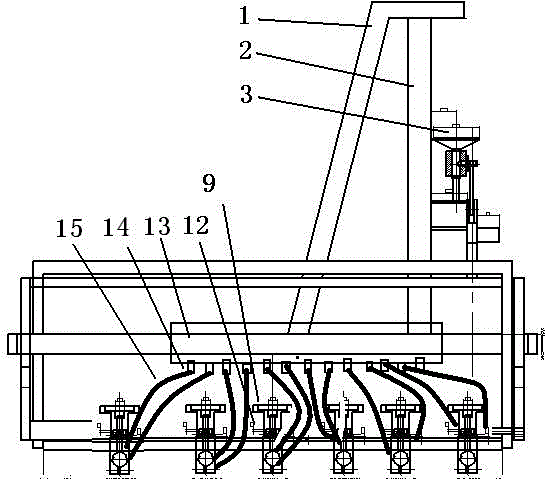

[0063] Such as figure 1 , figure 2 As shown, an auxiliary heating device for insulating joints is composed of a nozzle assembly (12), a push bracket (1), a walking wheel (8) and an adjustable device. The mechanism handwheel (3) for adjusting the distance of the nozzle is used to adjust the distance between the nozzle and the heating bolt and nut by 15mm. When heating the fishtail splint, shake the heating nozzle up and down, shake the handle (2) or hit the fixed adjustment nozzle up and down position (7), and push and pull at the same time to make the heating device move back and forth, so that the flame is evenly sprayed up and down to the fishtail For the splint, heat up to the temperature to melt the fixing glue and remove the splint.

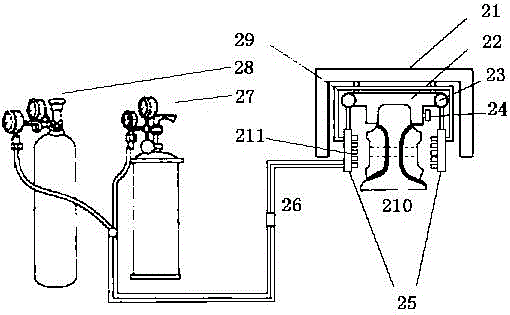

[0064] Such as image 3As shown, a rail heating device in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com