Printing roller structure and installation method

A printing roller and sleeve technology, which is applied in printing, printing machines, rotary printing machines, etc., can solve the problems of high storage environment requirements, difficult loading and unloading, excessive jumping of anilox rollers or plate rollers, etc., and achieve the storage environment. The effect of low requirements, low processing difficulty and high processing precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

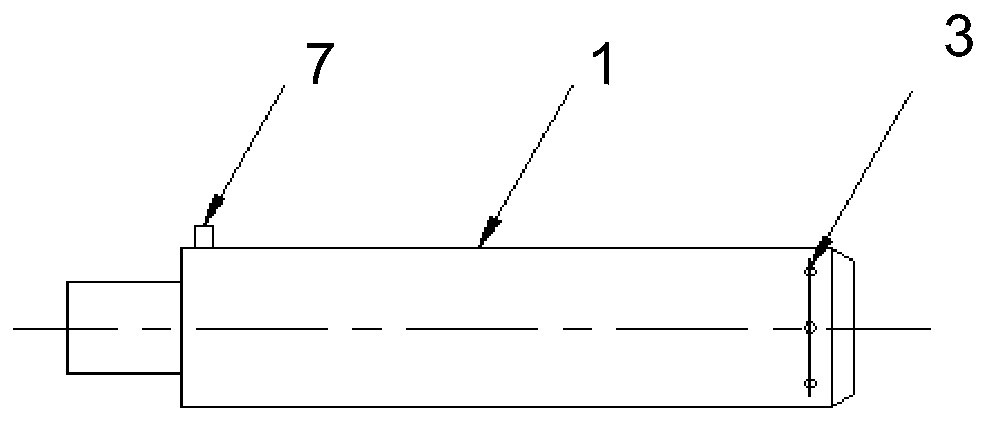

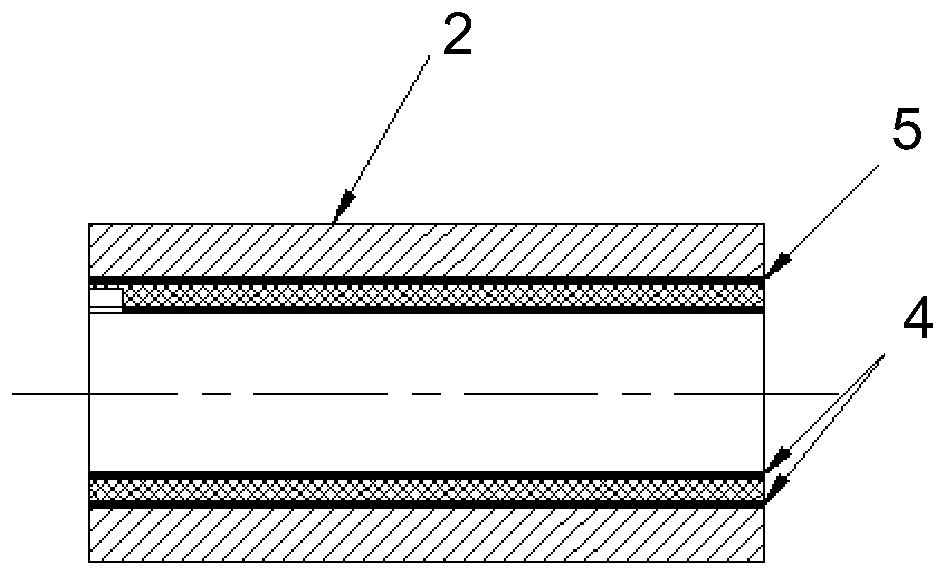

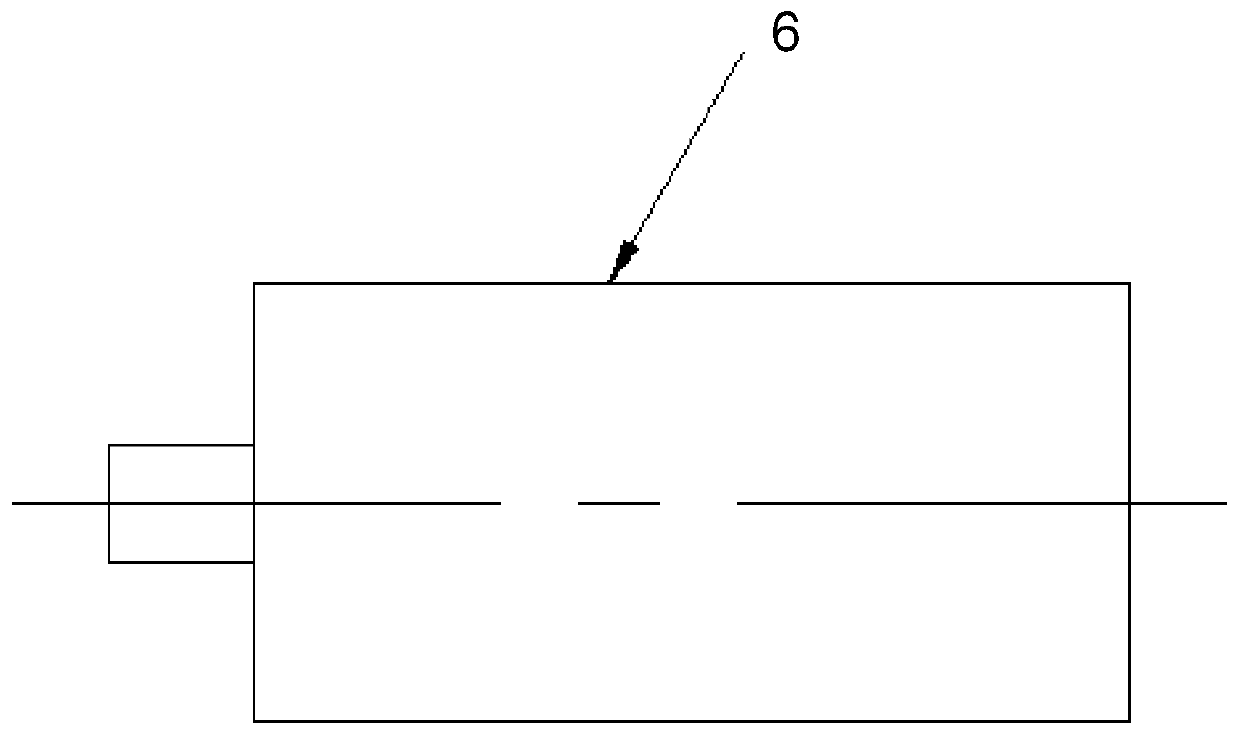

[0024] Printing cylinder structure of the present invention such as Figure 4 ~ Figure 6 As shown, it is the same as the prior art in that it also includes a shaft body 10 with a positioning pin 11 and a sleeve body 13 with an inner hole 12, the inner hole 12 also has a card slot 14, and the sleeve body 13 passes through the inner hole 12 is sheathed on the shaft body 10, and fits with the slot 14 through the positioning pin 11. Different from the prior art, the shaft body 10 has a hydraulic expansion mechanism, and a hydraulic expansion ring 15 is provided on the shaft body 10, and a corresponding hard alloy ring 16 is also provided in the inner hole 12 of the sleeve body 13, and the shaft body 10 is provided with a hydraulic expansion ring 15. The body 10 is in clearance fit with the inner hole 12, and the hydraulic expansion ring 15 and the alloy ring 16 are braced radially.

[0025] As an embodiment, the hydraulic expansion ring 15 has a pair, which are respectively provi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com