Prestressed concrete H-shaped beam plate

A prestressed, beam-slab technology, used in bridges, bridge materials, bridge construction, etc., can solve the problems of long construction period, high construction cost and high maintenance cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

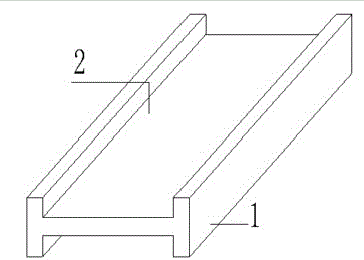

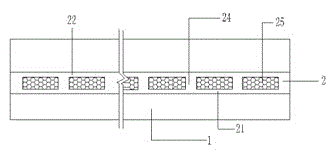

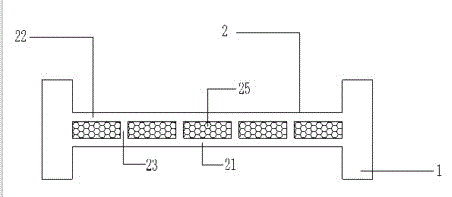

[0005] Such as Figure 1-3 As shown, this embodiment discloses a prefabricated prestressed concrete H-shaped beam slab, which is an H-shaped prefabricated component formed by a horizontal web 2 and two side beams 1 arranged along its length direction. The horizontal web 1 It is a reinforced concrete dense rib sandwich slab, and the two vertical side beams 2 are prestressed concrete rectangular beams arranged on both sides of the web along the length direction of the horizontal web and having the same length as the horizontal web. The horizontal web 2 is a frame structure surrounded by a lower panel 21, an upper panel 22 and intersecting longitudinal ribs 23 and transverse ribs 24 arranged between them, the longitudinal ribs 23 and the transverse ribs 24 The area between the lower panel 21 and the upper panel 22 is divided into several independent cavities, and the independent cavities are filled with corresponding filling blocks 25 . In order to improve the bearing capacity a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com