Assembled bridge deck slab

A prefabricated and bridge deck technology, applied in bridges, bridge parts, bridge construction, etc., can solve problems such as unsatisfactory processing effect and high processing difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

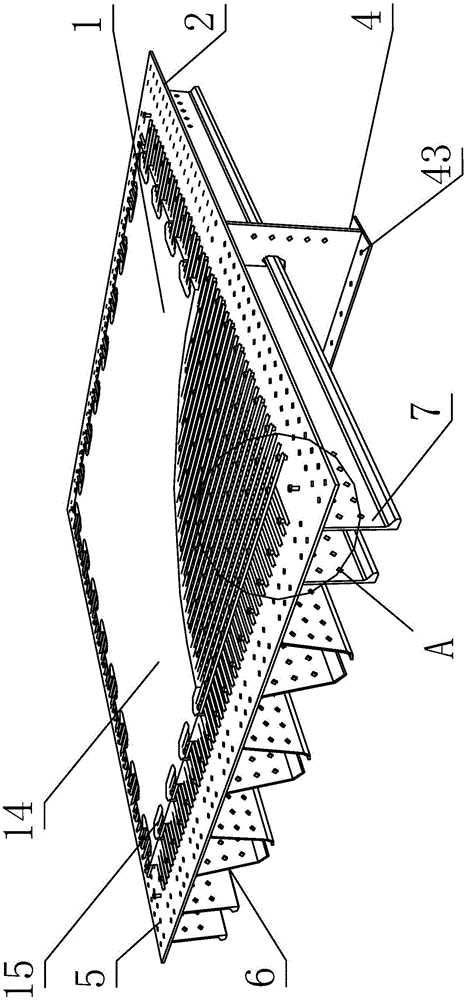

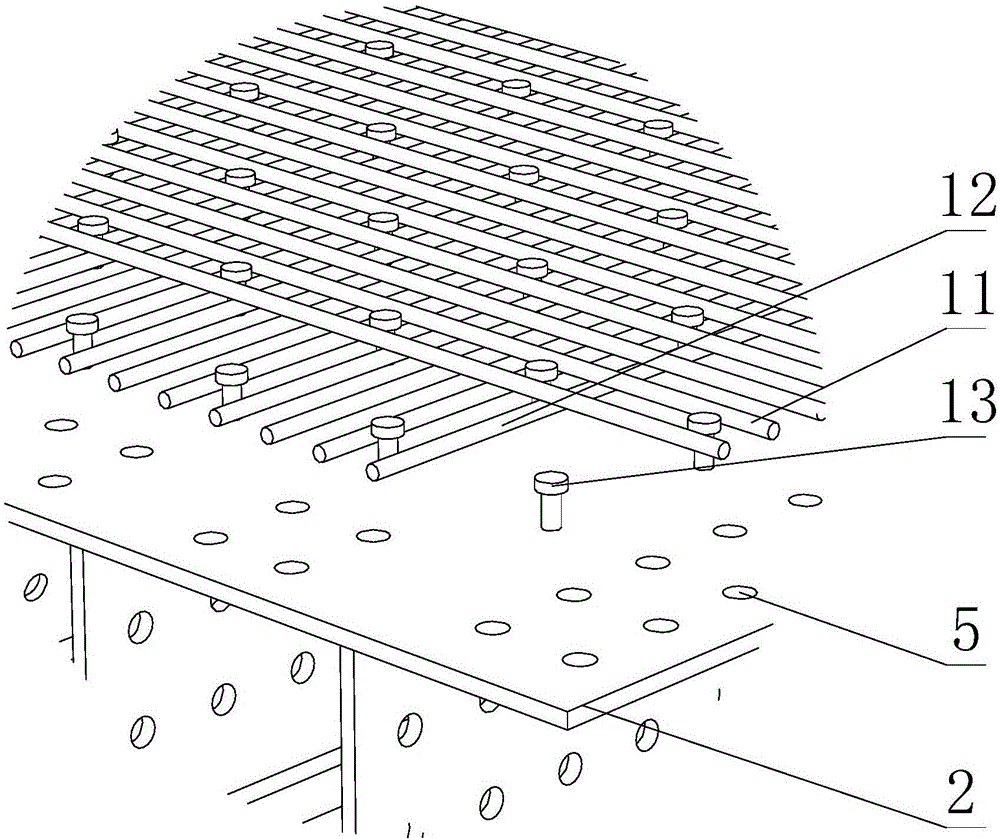

[0040] Such as Figure 1 to Figure 6 As shown, an assembled bridge deck includes a steel bridge deck and a structural layer 1 laid on the steel bridge deck, and connecting bolt holes 5 are arranged around the steel bridge deck.

[0041] In the prior art, the construction method of orthotropic steel-ultra-high-performance concrete composite bridge deck is to pour ultra-high-performance concrete on-site after the construction of orthotropic steel bridge deck is completed. The biggest disadvantage of on-site pouring is that the quality of concrete pouring is difficult to control , while ultra-high-performance concrete has strict requirements for construction quality, and its good mechanical performance and durability are all based on the premise that the construction quality meets the standard. At the same time, ultra-high-performance concrete has strict requirements on curing conditions. Generally, high-temperature steam curing is required, and special curing equipment is requir...

Embodiment 2

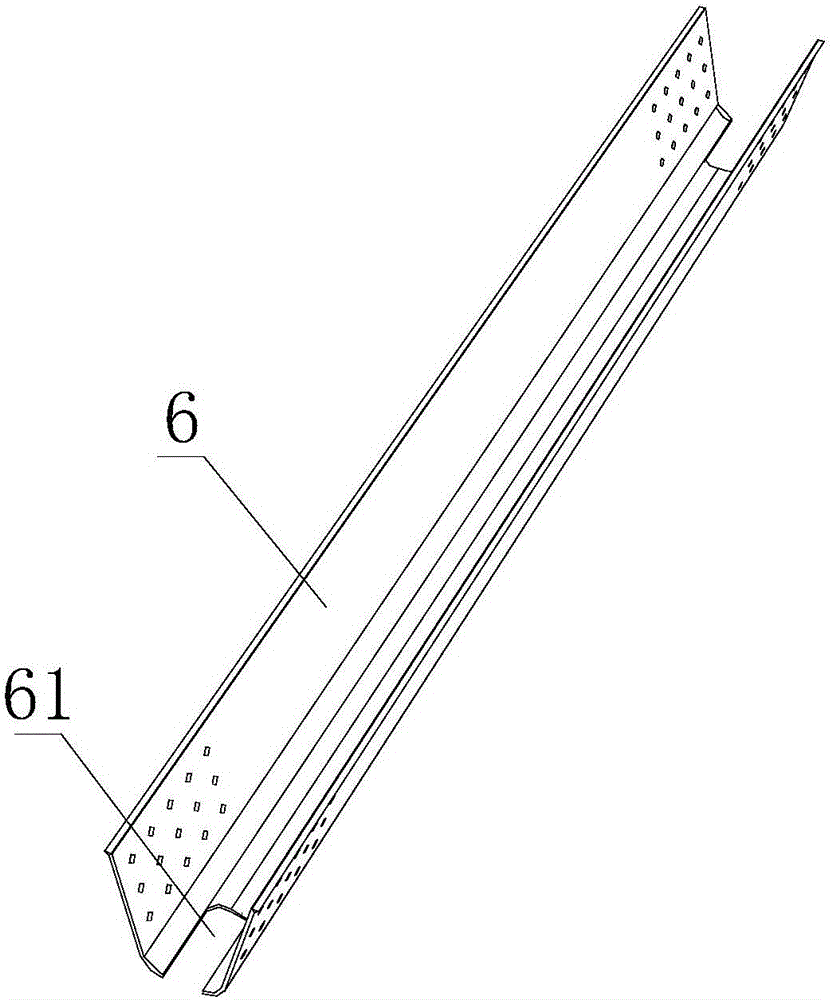

[0045] Such as Figure 1 to Figure 6 As shown, this embodiment is further limited on the basis of Embodiment 1: As a specific implementation of the steel bridge deck, the steel bridge deck includes a top plate 2, longitudinal ribs and transverse ribs 4, and there are multiple longitudinal ribs, The longitudinal ribs are parallel to each other, and the upper parts of the longitudinal ribs are fixedly connected with the top plate 2;

[0046] The transverse rib 4 and the longitudinal rib are perpendicular to each other, the transverse rib 4 is fixedly connected to each longitudinal rib, and the lower end of the transverse rib 4 is lower than the lower end of the longitudinal rib;

[0047] The structural layer 1 is laid on top of the roof 2;

[0048] Bolt holes 5 are provided around the top plate 2 , at both ends of the longitudinal ribs, and at both ends of the transverse ribs 4 .

[0049] In this scheme, the lower end of the transverse rib 4 is used as the connection part betw...

Embodiment 3

[0062] This embodiment further defines this case on the basis of any one of the technical solutions provided by any one of the above embodiments, such as Figure 1 to Figure 6 As shown, as a person skilled in the art, the adjacent fabricated bridge decks can be staggered up and down, and left and right staggered to realize the direct connection between the adjacent fabricated bridge deck steel bridge decks, but The above connection methods are inconvenient to determine the position of each fabricated bridge deck on the lower steel member of the bridge. Therefore, the connecting plate 3 is also included, and the connecting plate 3 is used as an intermediate connector between two adjacent fabricated decks to realize the Bolted connections between fabricated deck steel bridge decks. The connecting plate 3 is used as an intermediate connector between adjacent fabricated bridge decks, such as a plate-shaped structure provided with bolt holes, so that after the assembled bridge deck...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com