Tool provided with double tracks to conduct pushing, accumulating and slipping and construction method thereof

A technology of accumulative slip and double tracks, which is applied in the processing of building materials, construction, building construction, etc., can solve the problems of difficult sliding, large deflection under single beam and single track, and uneven force on the sliding structure. Avoid collision, facilitate sliding precision control, and facilitate the effect of pushing operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

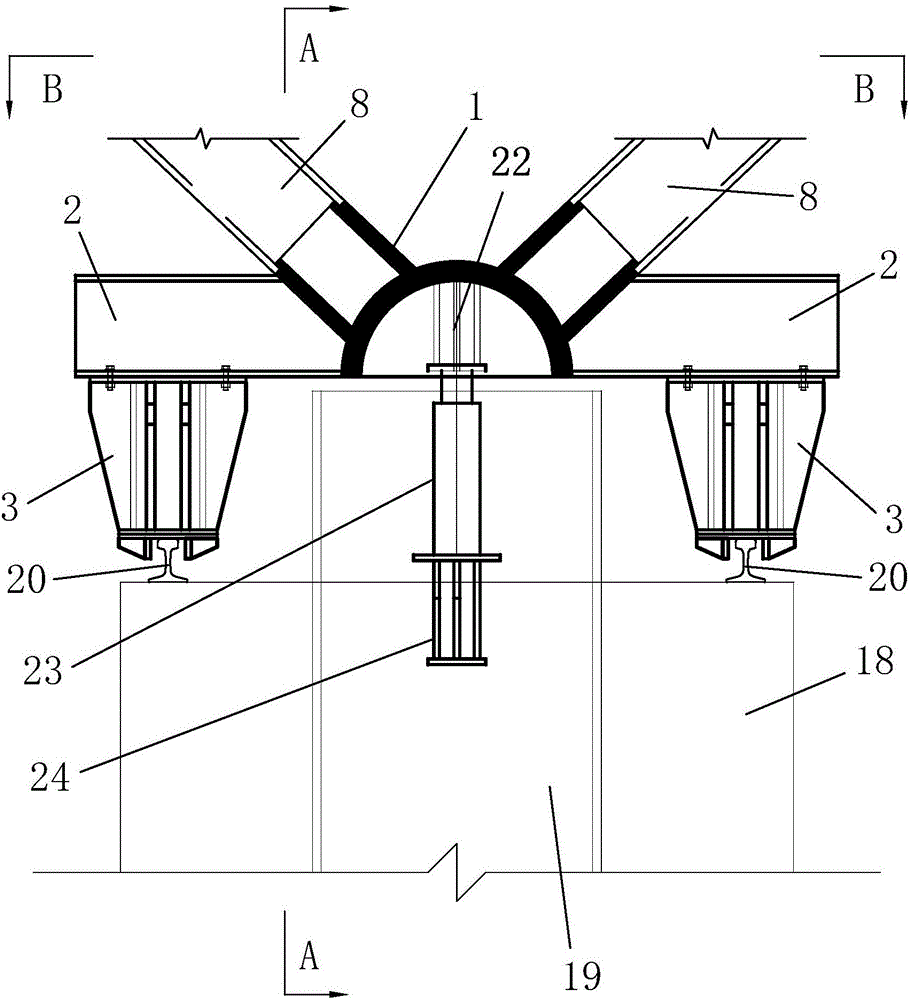

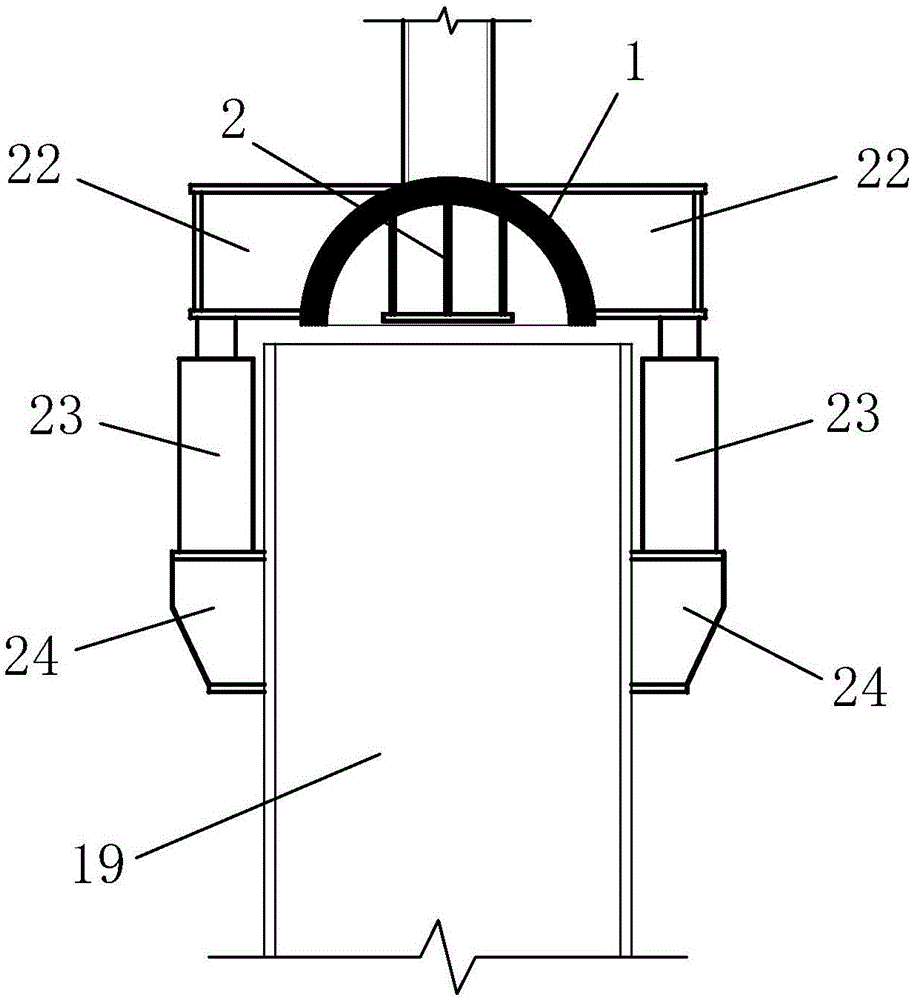

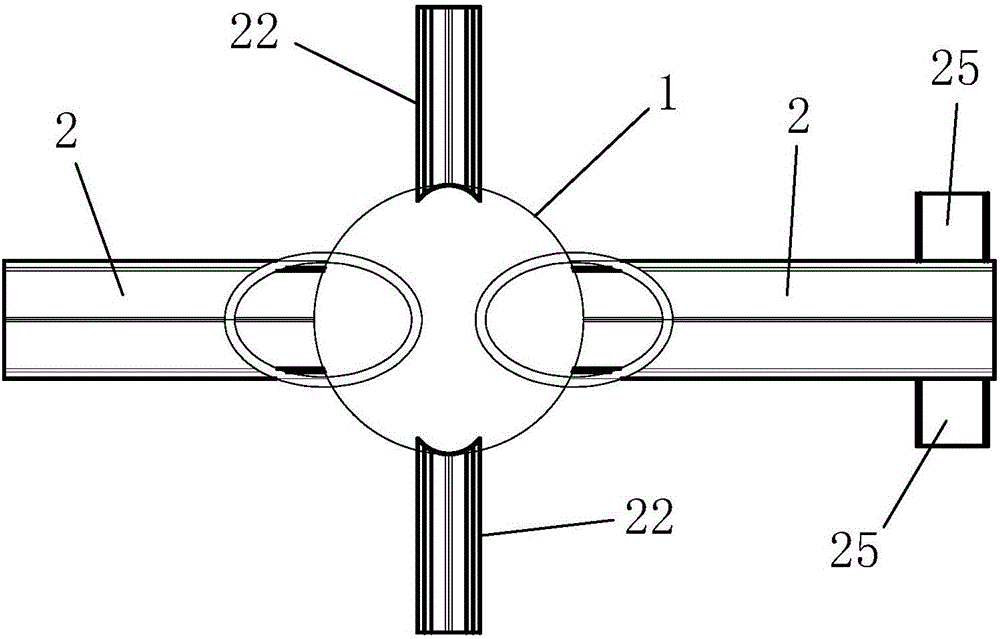

[0051] Such as Figure 1 to Figure 16 As shown, it is a kind of tooling with double tracks for pushing and accumulating sliding in the present invention, including the original column 19, track beam 18 and sliding track 20 arranged on the track beam 18, and also includes pushing and accumulating slip nodes, The main body of the sliding structure is placed in place and the steel strand is pulled up.

[0052] The jacking cumulative slip node includes a V-shaped column hemispherical support 1, a composite cross-section pole beam 2, a steel shoe 3, and a pushing device 21. The shoulder-pole beam 2 with combined section is arranged symmetrically along the center line of the V-shaped column hemispherical support 1 . The steel sliding shoes 3 are arranged at the bottom of the shoulder pole beam 2 of the combined section, and the steel sliding shoes 3 are arranged symmetrically along the center line of the V-shaped column hemispherical support 1 . The pushing device 21 is connected ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com