Lining oil tube and manufacturing process thereof

A manufacturing process and lining pipe technology, which is applied in the direction of drill pipe, casing, drilling equipment, etc., can solve the problems of accelerated lining pipe wear and distortion, slow speed of lining pipe shaping, and a large number of lining pipes, etc., to improve The effect of service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The following examples can enable those skilled in the art to understand the present invention more comprehensively, but the present invention is not limited to the scope of the described examples.

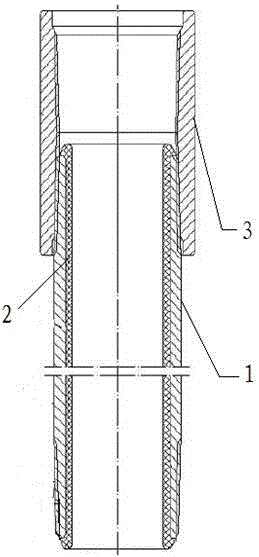

[0026] Such as figure 1 A lined oil pipe and its manufacturing process are shown, including an oil pipe 1, an inner liner pipe 2 and an oil pipe collar 3; the two ends of the oil pipe 1 are provided with external thread structures, and the two ends of the oil pipe collar 3 are provided with internal thread structures, corresponding The adjacent oil pipes 1 are threaded through the oil pipe collar 3; the oil pipe 1 has a built-in inner liner 2 with an interference fit with it, and the inner liner 2 is flanged at the nozzle of the oil pipe along the radial direction of the oil pipe to form a flanged nozzle. The outer diameter of the flanging nozzle is smaller than the minor diameter of the external thread of the oil pipe; a guiding tapered surface is arranged on the outer sur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com