Ball screw pair with automatic compensation of thermal deformation

A ball screw pair, ball screw technology, applied in the direction of transmission, belt/chain/gear, mechanical equipment, etc., to achieve the effect of improving accuracy and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

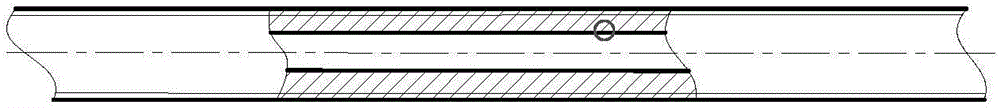

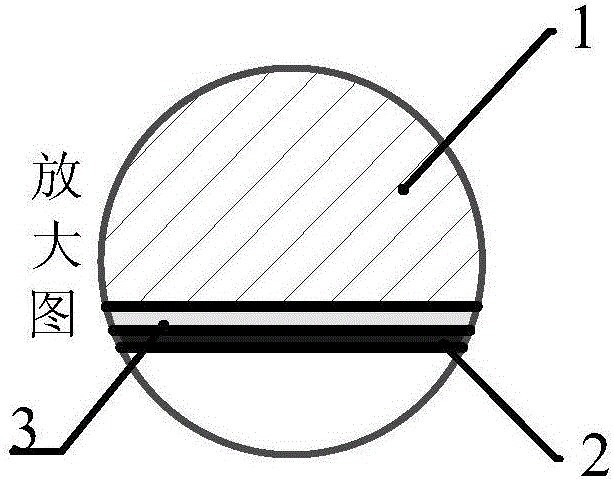

[0012] The following is attached Figure 1-2 , to further describe the device.

[0013] Step 1: Drill a through hole along the axial direction of the ball screw body 1.

[0014] Step 2: Arrange the aramid fiber 2 in the axial direction of the inner wall of the through hole, the aramid fiber 2 and the ball screw body 1 are bonded by the adhesive 3, and at the same time, make the length direction of the aramid fiber 2 and the through hole Axially consistent.

[0015] Step 3: Install the nut on the screw shaft of the ball screw body 1.

[0016] The lead screw expands when heated in the axial direction. Because the aramid fiber has a negative thermal expansion coefficient in the length direction, it shrinks when heated, and has a "pull back" effect on the lead screw in the axial direction, so that the thermal deformation of the lead screw is obtained. Automatic compensation.

[0017] A through hole is drilled in the axial direction of the ball screw body 1, and aramid fiber is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com