A reusable pipe end seal

A technology of sealing device and pipe end, which is applied in the direction of drill pipe, casing, pipe components, etc., can solve the problems of invalid test, cumbersome process, pressure relief, etc., and achieve the effects of wide application range, improved sealing performance and shortened process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

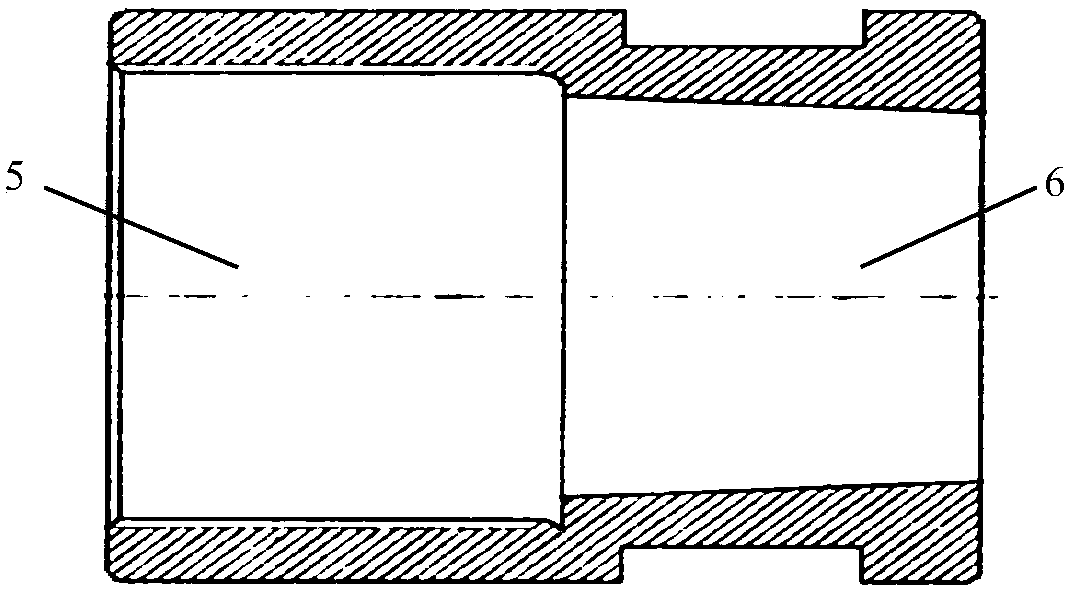

[0021] In the present invention, taking the coiled tubing of Φ38.1×3.4mm as an example, the sealing device used to seal the end of the coiled tubing includes a tapered ferrule, an outer tapered sleeve joint, a ferrule-type pipe joint and a nut. The specific dimensions are as follows:

[0022] Tapered ferrule: the inner diameter of the through hole 8 is 38.3mm, and the length is 40mm; the taper of the outer conical surface 7 is 3°, the outer diameter of the small mouth of the outer conical surface 7 is 41.2mm, and the outer diameter of the large mouth is 45.44mm; the tapered ferrule The outer wall has a long slit 9 with an open end, the long slit gap is 1.6mm, and the depth is 35mm. There are four long slits 9 in total, and the outer wall is evenly divided into 4 petals.

[0023] Outer taper sleeve joint: the diameter of the small opening of the tapered hole 6 is 41.29mm, the diameter of the large mouth is 44.96mm, the taper of the tapered hole 6 is 3°, and the length of the tap...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com