All-glass heat tube type vacuum collector tube with reflux device

A technology of a vacuum heat collector tube and a reflux device is applied in the field of solar heat utilization, which can solve the problems of weakening the liquid-vapor circulation of the heat collecting tube, weakening the heat transfer efficiency of the heat collecting tube, and rising of the gaseous heat transfer working medium, so as to prevent the liquid working medium from drying up, The effect of improving safety and reducing the amount of liquid filling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

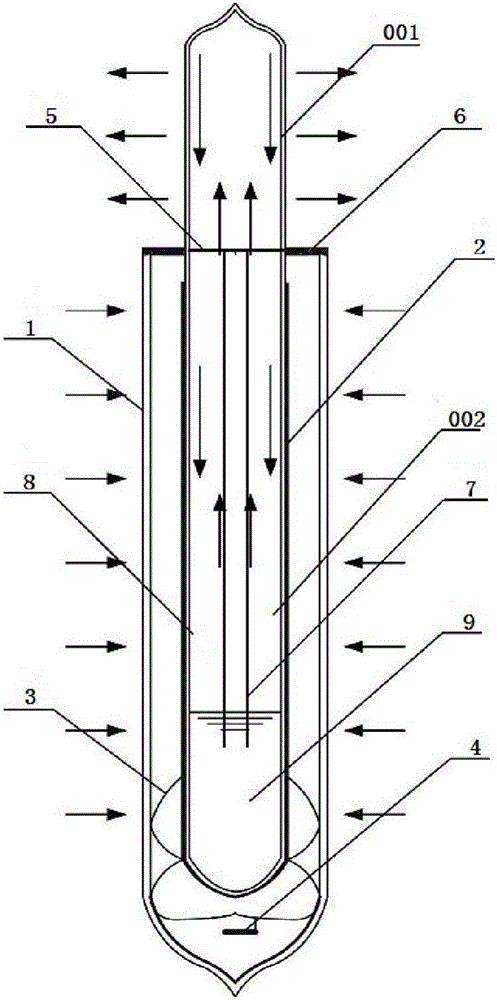

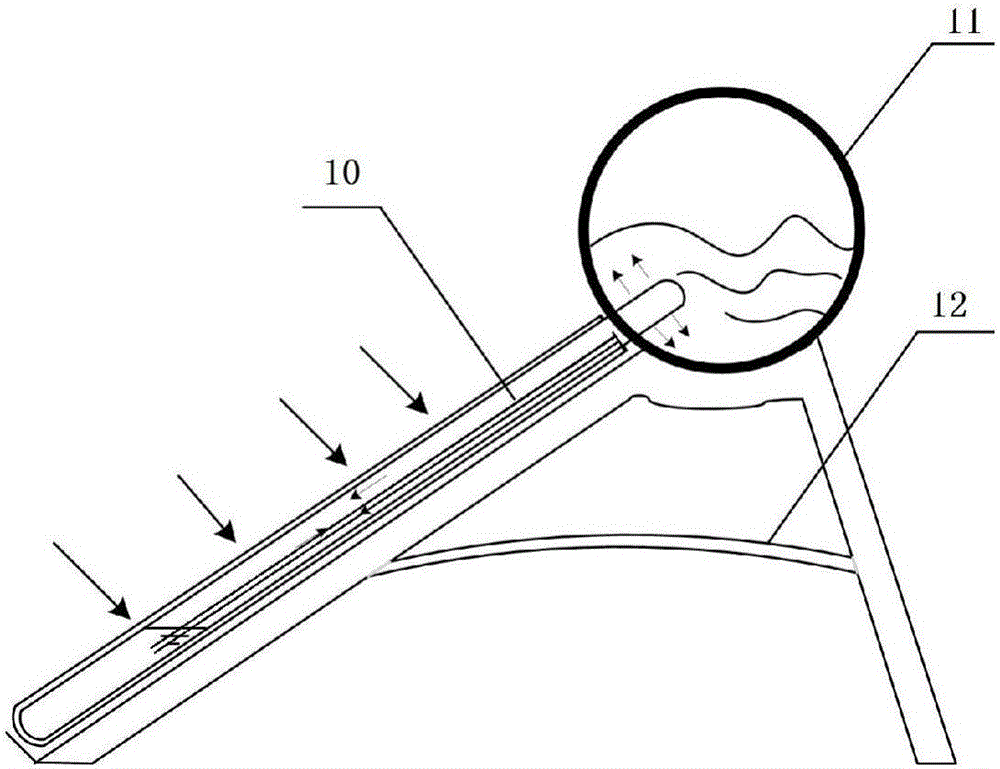

[0027] The core of the present invention is to provide a kind of all-glass heat pipe vacuum heat collecting tube 10 (hereinafter referred to as heat collecting tube) with a reflux device. The present invention will be further described below in conjunction with the accompanying drawings. It should be understood that these embodiments are only used to illustrate the present invention. It is not intended to limit the scope of the present invention. After reading the present invention, modifications to various equivalent forms of the present invention by those skilled in the art all fall within the scope defined by the claims of the present application.

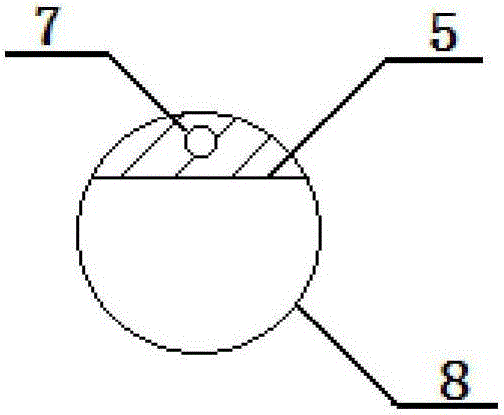

[0028] An embodiment of the present invention, such as figure 1 , 2 As shown, the main structure includes a glass outer tube 1 , a return device (ie, a baffle plate 5 and a conduit 7 ) and a glass heat pipe 8 . The inside of the glass heat pipe 8 contains a heat transfer medium 9 and has a certain degree of vacuum. The length ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap