Experiment device and experiment method for simulating thermal jet flow interference

An experimental method, jet flow technology, applied in the direction of measuring device, aerodynamic test, machine/structural component test, etc., can solve the problems of high cost of engine experiment, difficult experiment, wind tunnel corrosion, etc., and achieve strong engineering practicality Value, reduced experiment difficulty, low heat load effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

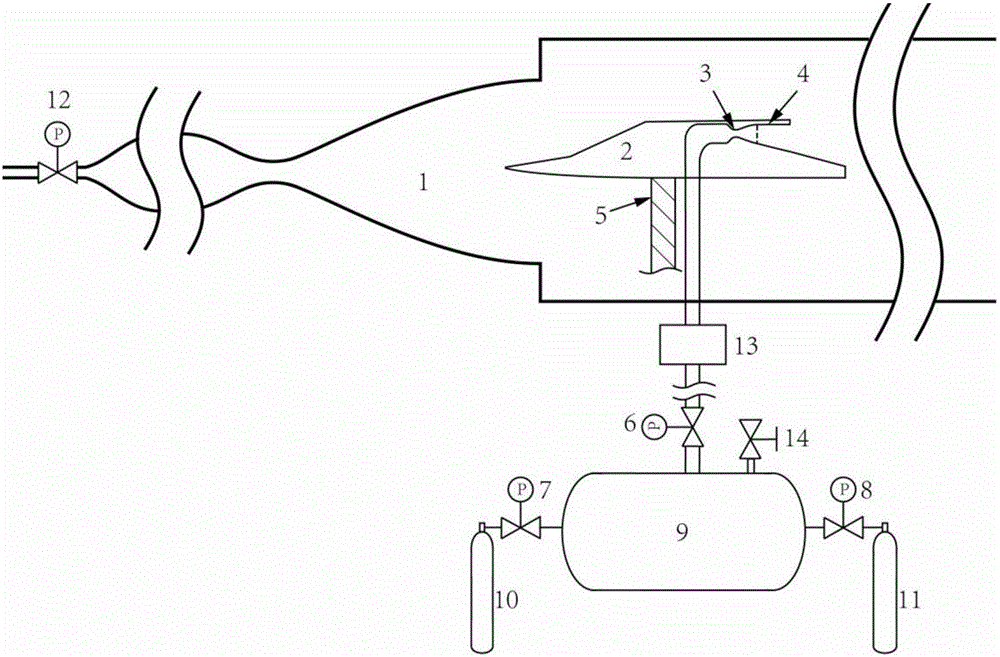

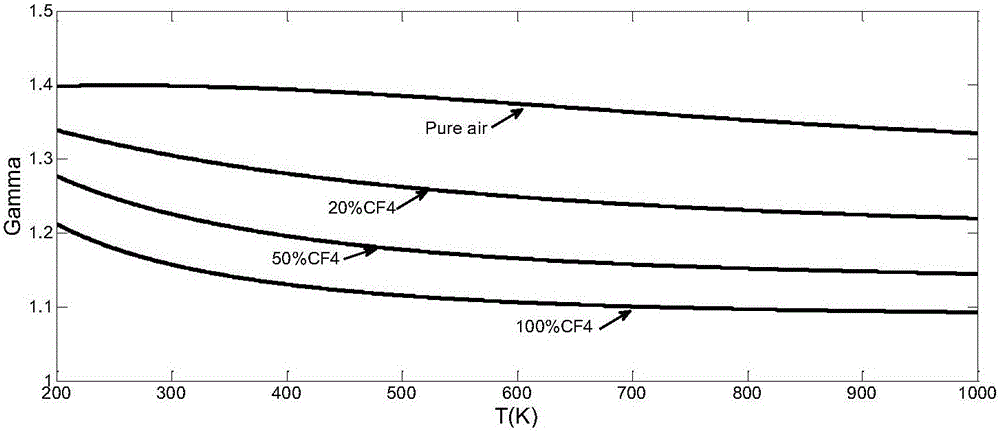

[0029] An experimental method for simulating thermal jet interference. The wind source is compressed and expanded by a hypersonic wind tunnel 1 and then becomes a hypersonic air flow to provide the outer flow for the experiment. CF4 or SF6 gas is mixed with air to provide the inner jet flow for the experiment. Control the molar mixing ratio and temperature of CF4 / SF6 gas and air to obtain the specific heat ratio required by the experiment, so as to meet the requirements of the jet specific heat ratio simulation in the experiment.

Embodiment 2

[0031] This embodiment provides an experimental method for simulating thermal jet interference. Before the experiment, the required specific heat ratio is determined according to the experimental state, and the molar ratio of CF4 or SF6 gas and air is calculated according to the specific heat ratio. The partial pressure ratio of CF4 or SF6 gas and air is obtained by the theorem of partial pressure. During the experiment, the pressure of CF4 or SF6 gas and the pressure of air are controlled according to this partial pressure ratio, and the mixed gas is heated to the required experimental temperature. Flow into the Laval inner nozzle 3, so as to realize the specific heat ratio required by the experiment, and generate the model nozzle inlet conditions required for the experiment, and then the mixed gas flows into the model nozzle 4, so as to carry out the thermal performance experiment of the model nozzle 4 Research.

[0032] The experimental specific heat ratio is between 1.1 an...

Embodiment 3

[0036] Such as figure 1 As shown, this embodiment provides an experimental device for simulating thermal jet interference, including a hypersonic wind tunnel 1, an experimental model 2 inside the hypersonic wind tunnel 1, a bracket 5 supporting the experimental model 2, and fixed on the bracket 5 The Laval inner nozzle 3, the model nozzle 4 connected with the Laval inner nozzle 3, the Laval inner nozzle 3 is used to provide the required inlet flow field for the model nozzle 4, and the valve 12 is connected between the wind source and the hypersonic speed The pipeline of the wind tunnel is used as a switch to open the hypersonic wind tunnel. The inlet of the Laval inner nozzle 3 is connected to the outlet of the heater 13, and the inlet of the heater 13 is connected to the outlet of the gas storage tank 9 through the dynamic feedback regulating valve 6. One inlet of the gas tank 9 is connected to the air cylinder 10 through the first electromagnetic pressure regulating valve 7 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com