Food safety fast inspection special sample crushing quantitative sampler

A food safety and quantitative sampling technology, which is applied in the preparation of test samples, sampling, sampling devices, etc., can solve the problems of cumbersome process, labor-intensive work, failure to achieve the expected purpose, etc., and achieve the effect of simple setting-out operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] In order to better understand the present invention, the present invention will be further described below in conjunction with specific embodiments and accompanying drawings.

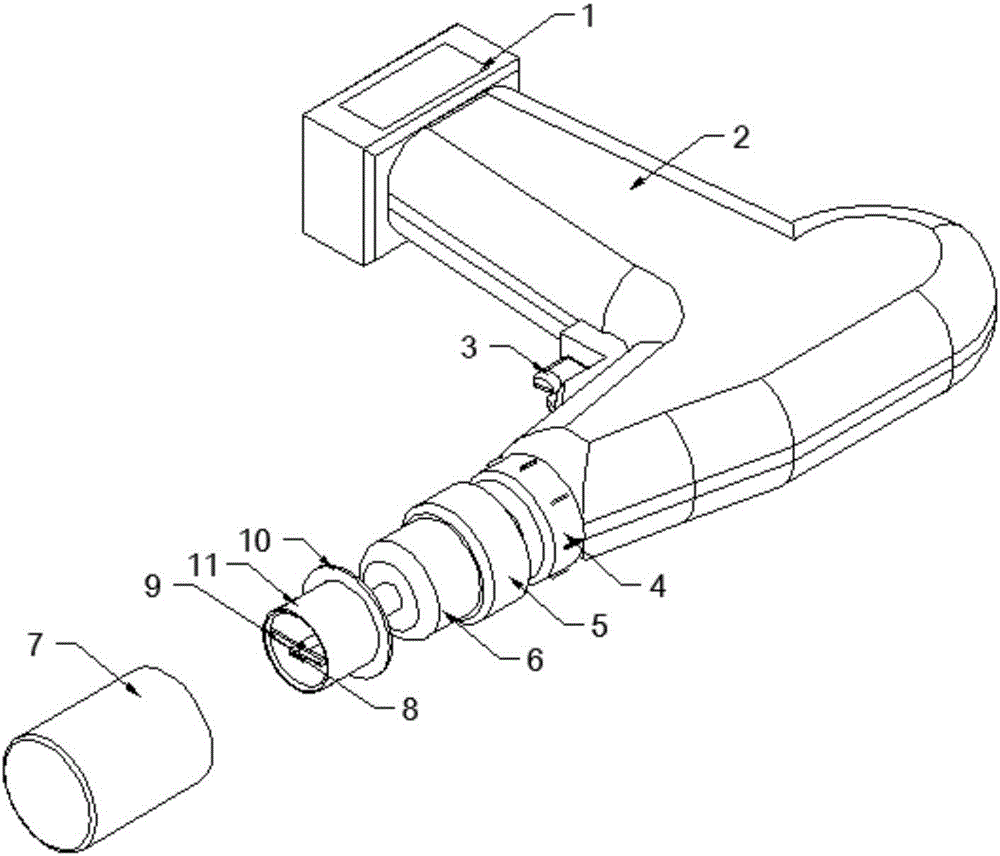

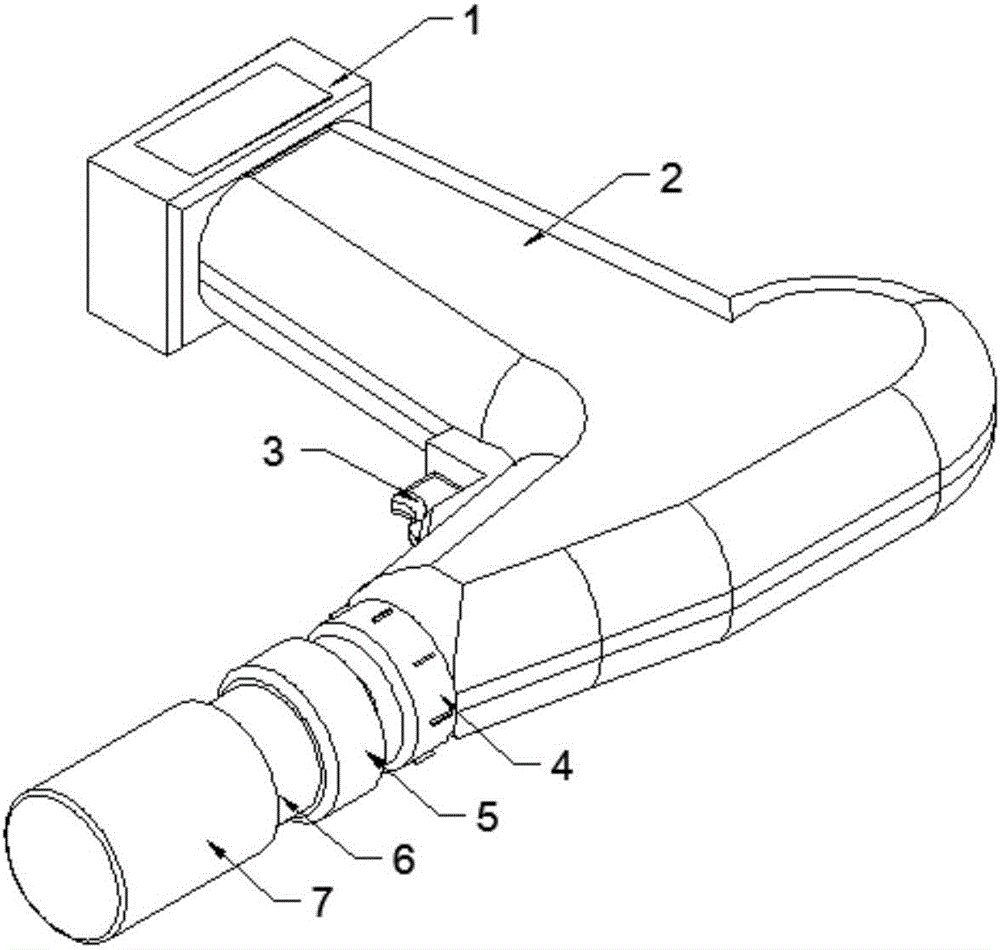

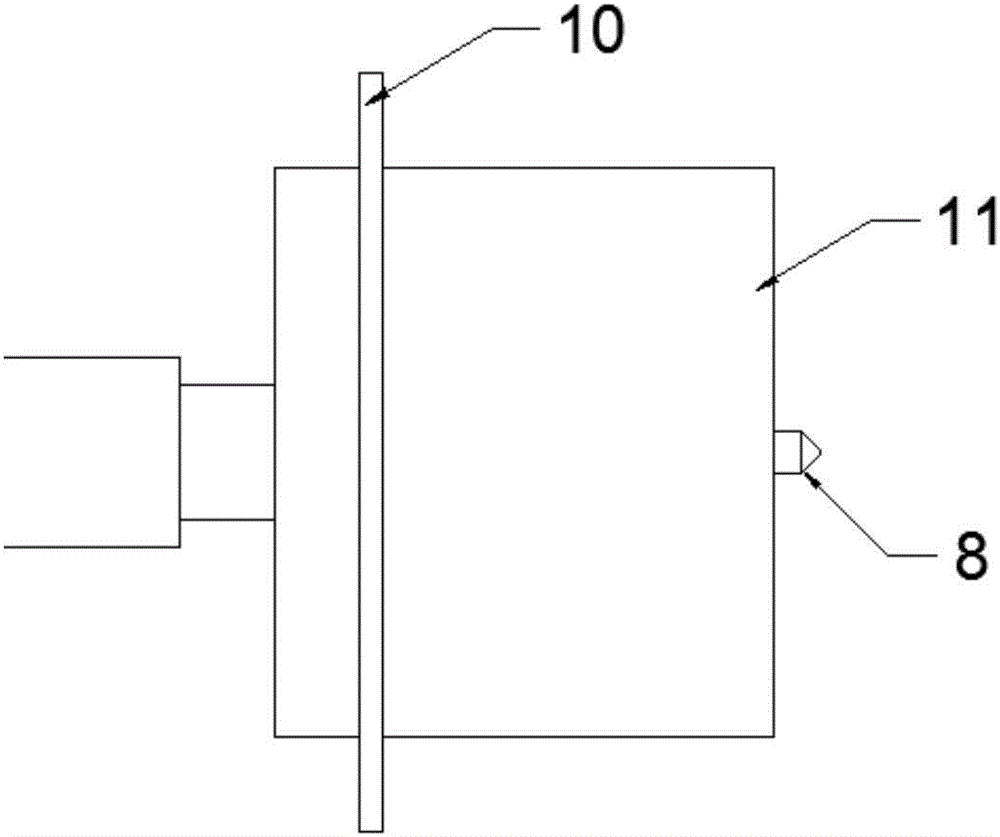

[0029] Such as Figure 1-6 As shown, a special sample pulverization quantitative sampler for food safety quick inspection, including the main body of the sampler, a pistol-shaped protective shell 2 covering the outside of the sampler, a blade 9 for crushing samples of the sampler, a central axis drill bit 8, a semi-quantitative A sample cup 11, a cutter head sheath 7, a reversible motor 4 and a mobile power source 1 composed of a lithium battery pack.

[0030] In order to make the rotational speed provided by the motor 4 both automatic and manual, the central shaft between the semi-quantitative sample cup 11 and the motor 4 is fitted with a frequency converter 6 and a frequency converter for automatically regulating the rotational speed of the motor. Gearbox 5 for manual control of motor speed. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com