Self-adjusting clamp head for macromolecular material multi-sample friction and abrasion tester for oilfield

A friction and wear test, self-adjusting technology, applied in the direction of analyzing materials, testing wear resistance, instruments, etc., to meet the requirements of test accuracy and solve the effect of deviation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

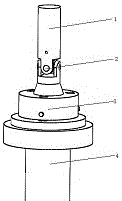

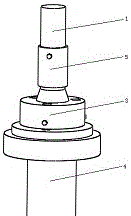

[0021] In order to further understand the invention content, characteristics and effects of the present invention, the following specific implementation content is listed below, and the detailed description is as follows in conjunction with the accompanying drawings.

[0022] see Figure 1-Figure 2 , a kind of self-adjusting collet used for multi-block friction and wear testing machine of polymer material for oil field, comprising transmission shaft 1, cross shaft universal joint 2, upper friction disc 3, lower friction disc 4, sleeve 5, the transmission The upper end of the shaft 1 is fixedly connected to the rotating power shaft of the friction and wear testing machine, and the lower end is fixedly connected to the cross shaft universal joint 2; the lower end of the cross shaft universal joint 2 is fixedly connected to the upper friction disc 3, and the upper friction disc 3 is set There is a test block holding hole, and a test block is installed in the test block holding ho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com