Method of manufacturing a modular damper

a manufacturing method and damper technology, applied in the field of dampers, can solve the problems of oem scrapping, adverse damping characteristics of dampers, and the same problem applies to damper base valves, etc., to achieve the effect of increasing handling, small equipment, and increasing profitability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

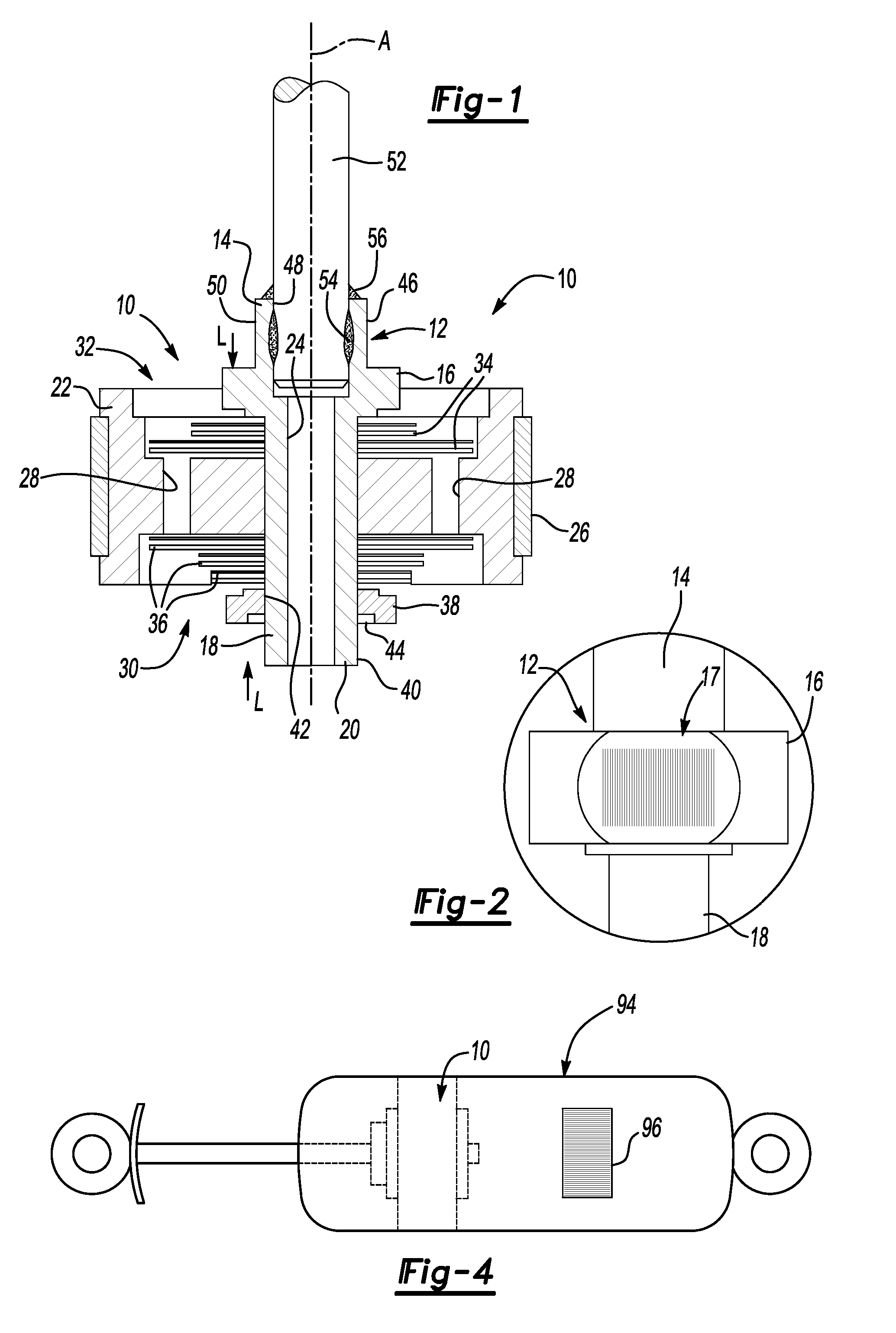

[0020] A piston valve assembly 10 of the present invention is shown in FIG. 1. The assembly 10 includes an inventive hub 12 that is designed to be used with different sized pistons and deflection discs to facilitate a more modular damper assembly. The hub 12 includes a first end 14 that is adapted to receive a piston rod. The first end 14 includes a shoulder 16 and a neck 18 extending from the shoulder 16 to a second end 20. The hub 12 is preferably marked with identifying information 17, for example by laser etching a bar code, that may be indicative of the components that will be installed on the hub 12 that will provide the particular piston valve assembly configuration, as shown in FIG. 2.

[0021] A piston 22 having a hole 24 is installed onto the hub 12 with the neck 18 received in the hole 24. Different sized pistons may be used on the same hub, for example, 25 mm, 30 mm, or 35 mm diameter pistons having the same sized central hole 24 could fit on the same hub. The neck 18 has ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com