Fuzzy C-means clustering-based on-line monitoring method for quality of slurry of desulfurization system

A technology of mean clustering and desulfurization system, applied in measuring devices, instruments, scientific instruments, etc., can solve the problems of slurry foaming and overflowing, unable to do laboratory analysis at any time, and only suitable for regular sampling or sampling inspection.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

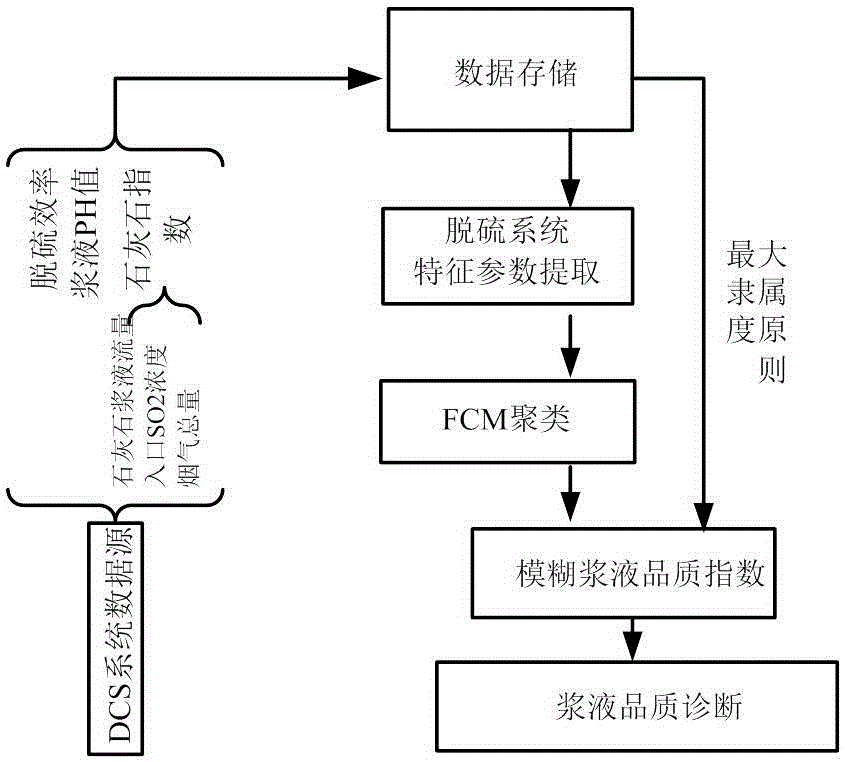

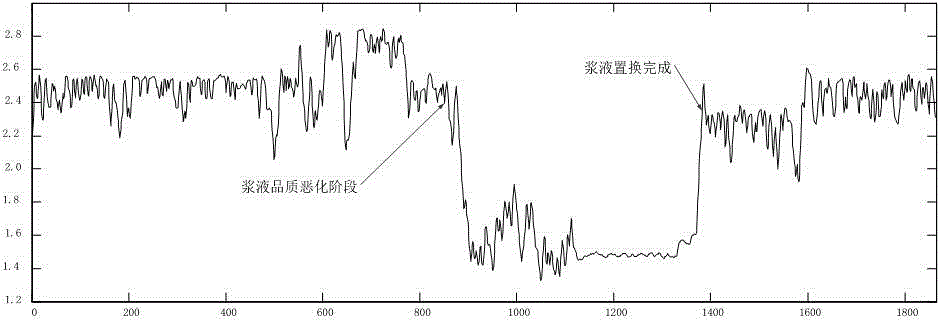

[0044] The online monitoring method of slurry quality in desulfurization system based on fuzzy C-means clustering in this embodiment includes the following steps:

[0045] Step 1. Obtain the corresponding desulfurization efficiency and slurry pH value under different slurry quality conditions (good, medium, and poor) through the data input interface, and calculate the limestone index reflecting the relationship between limestone flow, SO2 inlet concentration, and total flue gas gamma.

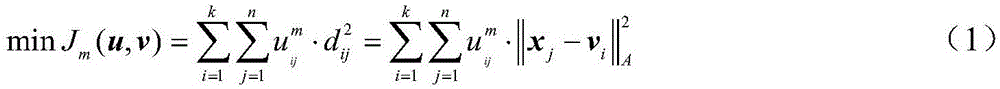

[0046] Step 2, using the fuzzy C-means clustering algorithm to determine the degree to which each data point belongs to a certain cluster. In the FCM clustering algorithm, it will finite sample set x={x 1 , x 2 ,...x n},x i ={Desulfurization efficiency, ph value, limestone index} is divided into category l (2≤l≤n). Any sample point will not be strictly divided into a certain category, but belongs to l different domains with a certain degree of membership.

[0047]

[0048]

[0049] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com