Vacuum testing device for measuring gas Townsend discharge parameters

An experimental device, vacuum technology, applied in the direction of measuring device, measuring electricity, measuring electrical variables, etc., can solve the problems of low working pressure, large sealing design, difficulty, etc., to improve air tightness, prevent leakage and interference, ensure The effect of accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be described in detail below in conjunction with the accompanying drawings.

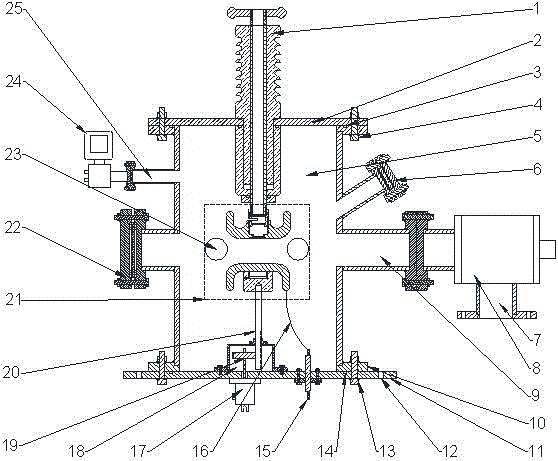

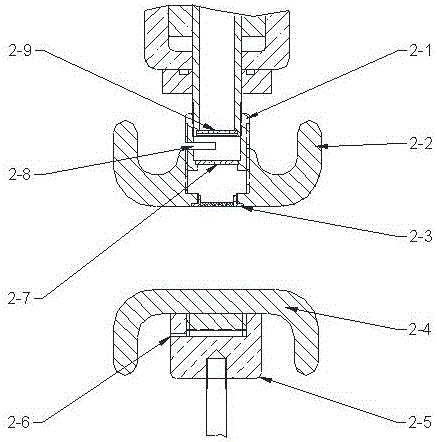

[0021] combine figure 1 and figure 2 As shown, the invention discloses a vacuum experimental device for measuring gas Thomson discharge parameters, which is characterized in that it includes a photoelectric double-channel high-voltage sealing sleeve 1, a discharge chamber upper cover 2, a vacuum discharge chamber 5, and a vacuum discharge chamber Extended observation window 6, vacuum system connection flange 7, vacuum baffle valve 8, vacuum system connection airway 9, vacuum discharge chamber lower seat ring 10, vacuum discharge chamber lower cover 11, vacuum discharge chamber platform fixing screw hole 12, Bottom cover sealing bolt 13, vacuum electrode 15, lower electrode connecting wire 16, sealing transmission package 18, lower electrode screw 20, discharge gap 21, main observation window 22 of vacuum discharge chamber, expansion connection port 23 of vacuum dis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com