Quick fault detection system for spacecrafts

A detection system and fault detection technology, applied in the field of aerospace measurement and control, can solve the problems of reduced usability of detection methods, difficulty in measuring and obtaining fault symptoms, difficulty in obtaining satisfactory detection results, etc., and achieve low hardware requirements, easy knowledge acquisition and analysis, The effect of high efficiency of rule reasoning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

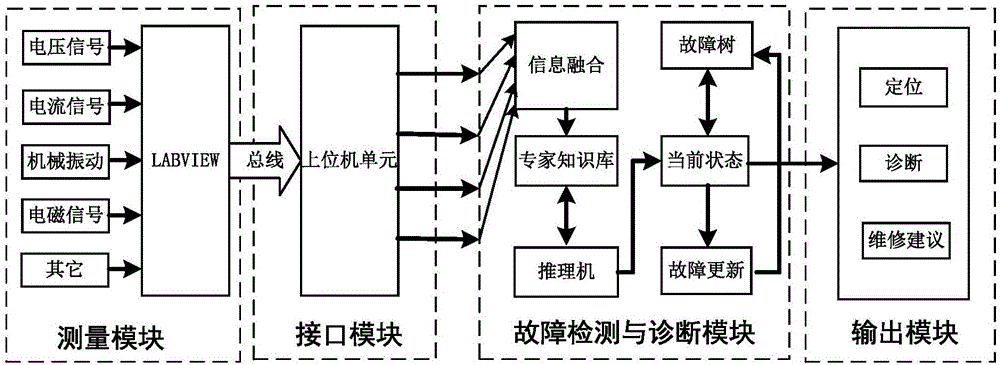

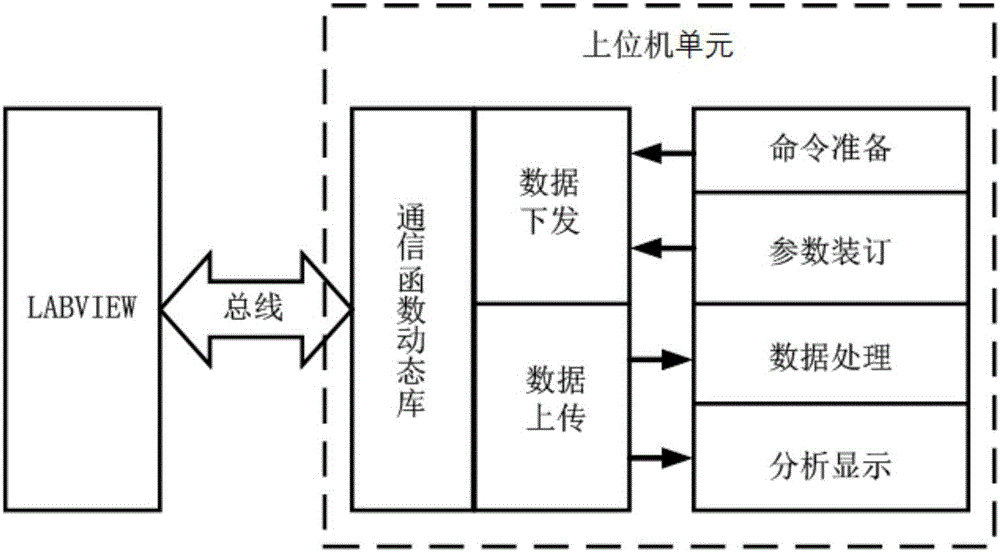

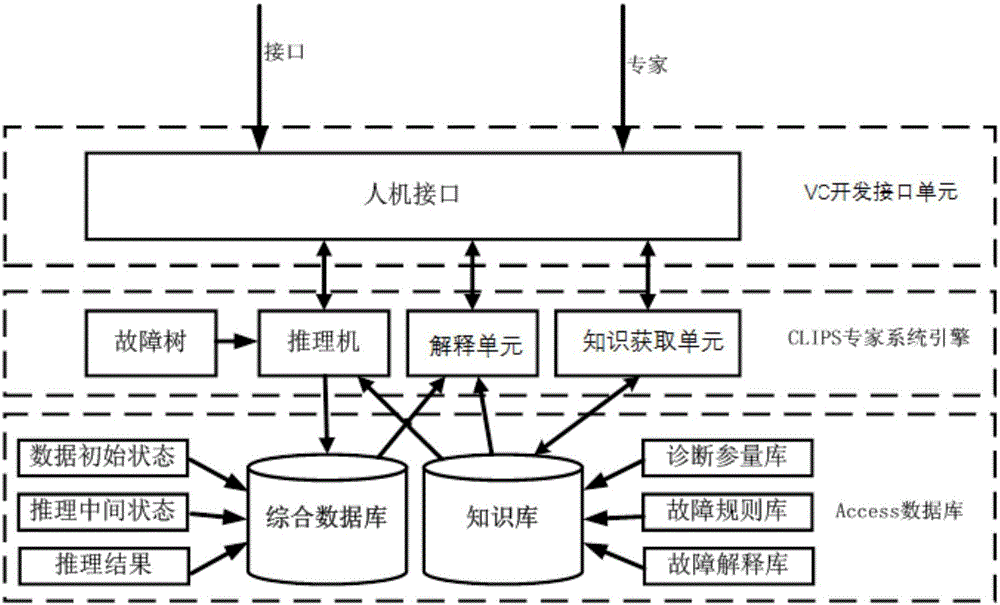

[0015] Such as figure 1 As shown, the present embodiment includes: a measurement module, a fault detection and detection module, an interface module and an output module, wherein: the measurement module receives the state signal of the sensor and inputs the signal conditioning circuit of the LABVIEW platform in the measurement module to obtain the measurement data of the electrical analog signal ;The interface module receives the measurement data, and integrates the measurement data into a matrix form according to time; the fault detection and detection module performs information fusion on the integrated measurement data and transforms it into a CLIPS fact structure, and infers qualified measurements from the inference engine according to the rules of the expert knowledge base The data is then located and detected by fault tree rules, and maintenance suggestions are obtained; the output module displays the positioning and detection results and maintenance suggestions.

[0016...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com