High-temperature-resistant RFID tire electronic label and manufacturing method thereof

An electronic label and high-temperature-resistant technology, which is applied to record carriers used in machines, instruments, computer parts, etc., can solve the problems of reducing the safety factor of tires, easy to form air bubbles, and easy damage to labels, so as to improve the vulcanized rubber surface. Good high temperature effect, good overall strength effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] Below, in conjunction with accompanying drawing and specific embodiment, the present invention is described further:

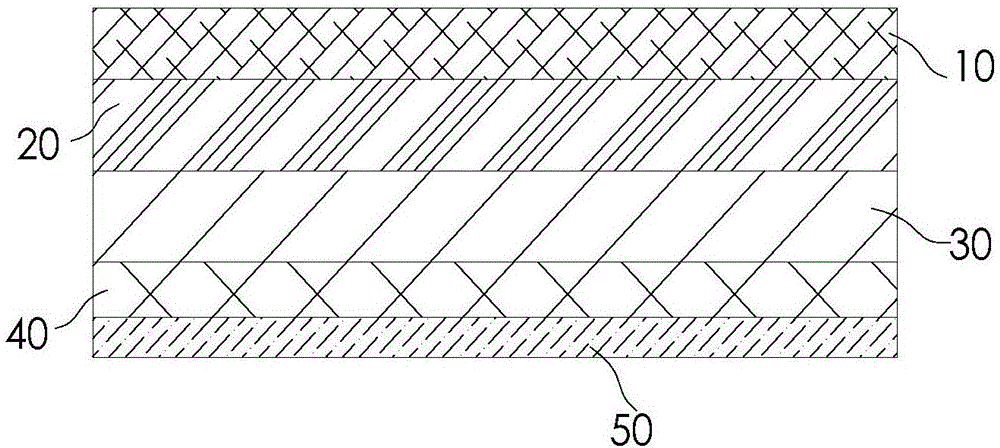

[0044] Such as figure 1 A high-temperature-resistant RFID tire electronic tag shown includes a film layer 10 , a cured adhesive layer 20 , an antenna layer 30 , a vulcanized adhesive layer 40 and a release film layer 50 sequentially stacked and fixed from top to bottom. Specifically, the film layer 10 is a PEN film, a PI film, a PEEK film, a PPS film, a PEI film or a PAI film, and the cured adhesive layer 20 is an epoxy resin adhesive. In addition, the antenna layer 3030 includes an RFID chip and an etched metal layer, and the RFID chip is fixed inside the etched metal layer by reflow soldering.

[0045] On the basis of the above structure, the electronic label can be implanted into the tire as a whole by tearing off the release film layer 50 as the protective surface; at the same time, the product information is built into the RFID chip, so that the t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com