Workpiece surface defect detection method and device

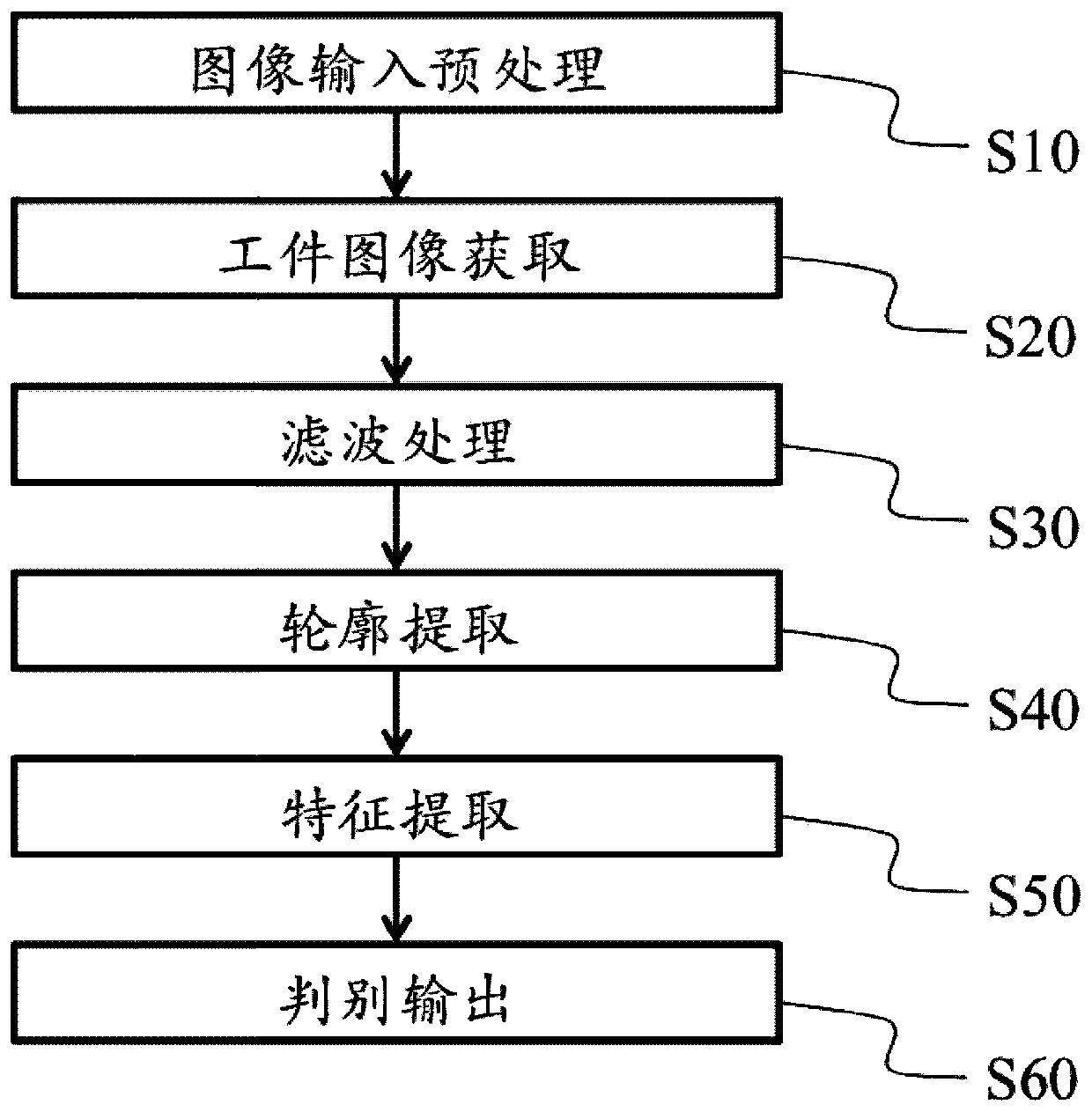

A workpiece surface and defect detection technology, which is applied to computer parts, character and pattern recognition, image analysis, etc., can solve the problems of high false detection rate, poor real-time performance, and impact on the accuracy and reliability of evaluation, so as to avoid interference, The effect of reducing the amount of computation and improving the accuracy of discrimination

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

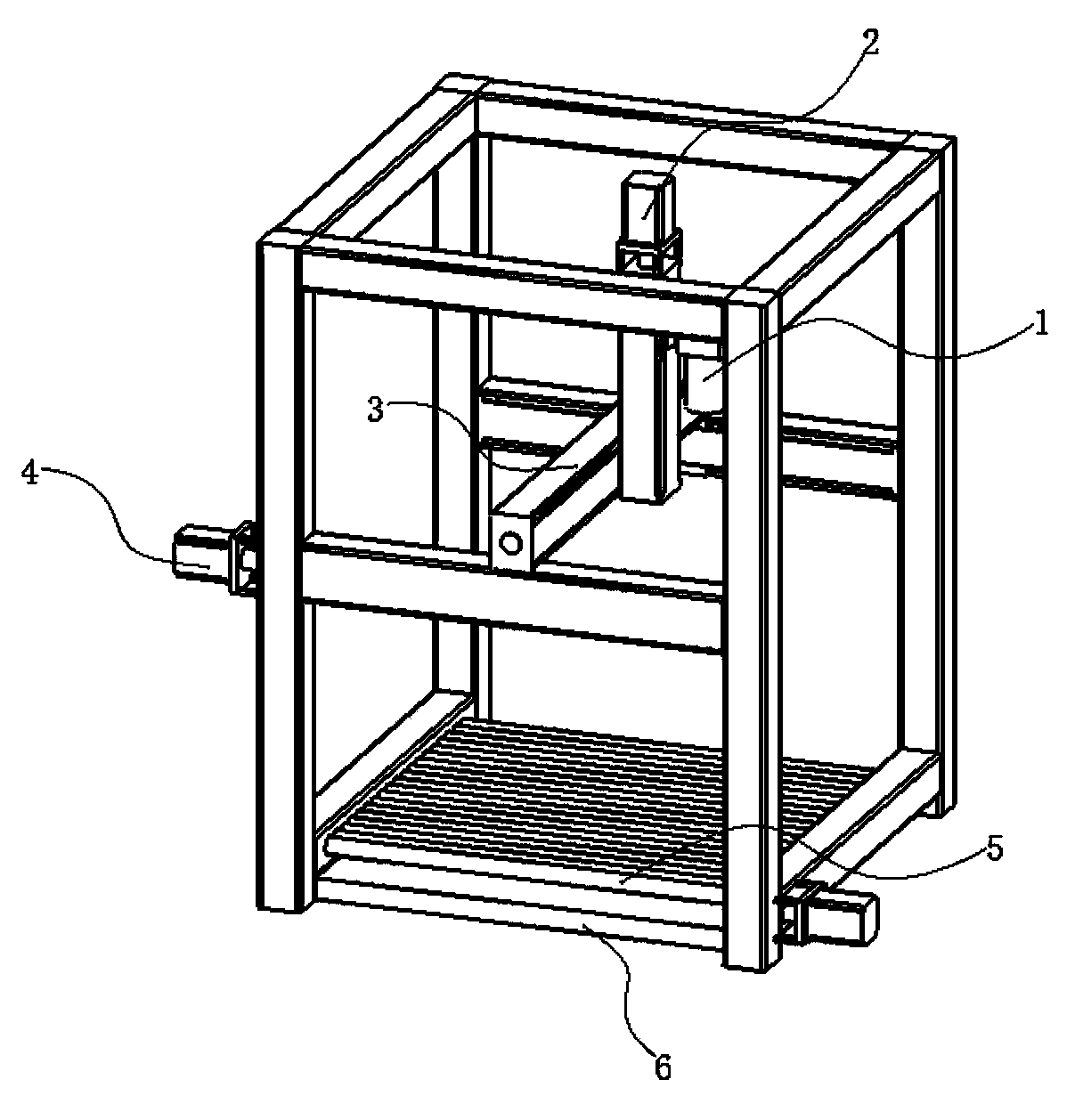

[0044] An apparatus device implementing various embodiments of the present invention will now be described with reference to the accompanying drawings. In the following description, use of suffixes such as 'module', 'part' or 'unit' for denoting elements is only for facilitating description of the present invention and has no specific meaning by itself. Therefore, "module" and "component" may be used mixedly.

[0045] The workpiece surface defect detection method and device can be implemented in various forms. For example, the processing methods and apparatuses described in this disclosure may include mobile device devices as well as stationary device devices. In the following, it is assumed that the terminal is a fixed equipment device. However, a person skilled in the art will appreciate that, in addition to elem...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com