Tea fermentation tank with ventilation duct

A technology of tea fermentation and ventilation duct, which is applied in tea treatment before extraction, etc. It can solve the problems of uncontrollable sanitation, high labor intensity, long production cycle, etc., and achieve uniform fermentation, good fermentation effect and stable temperature in the tank

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

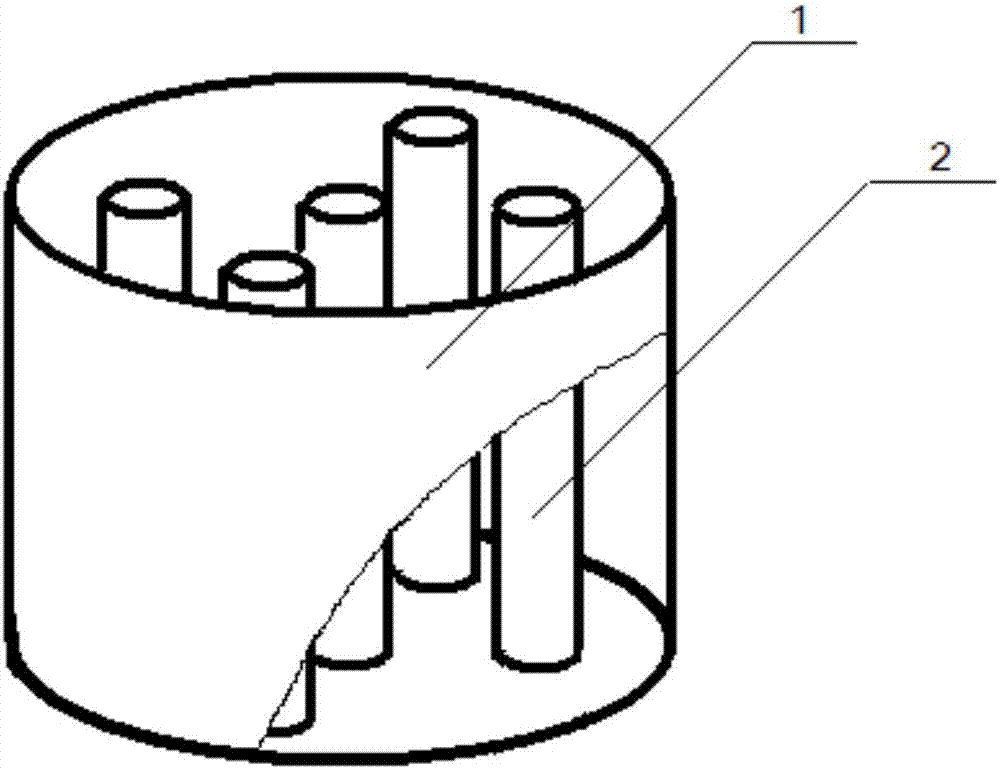

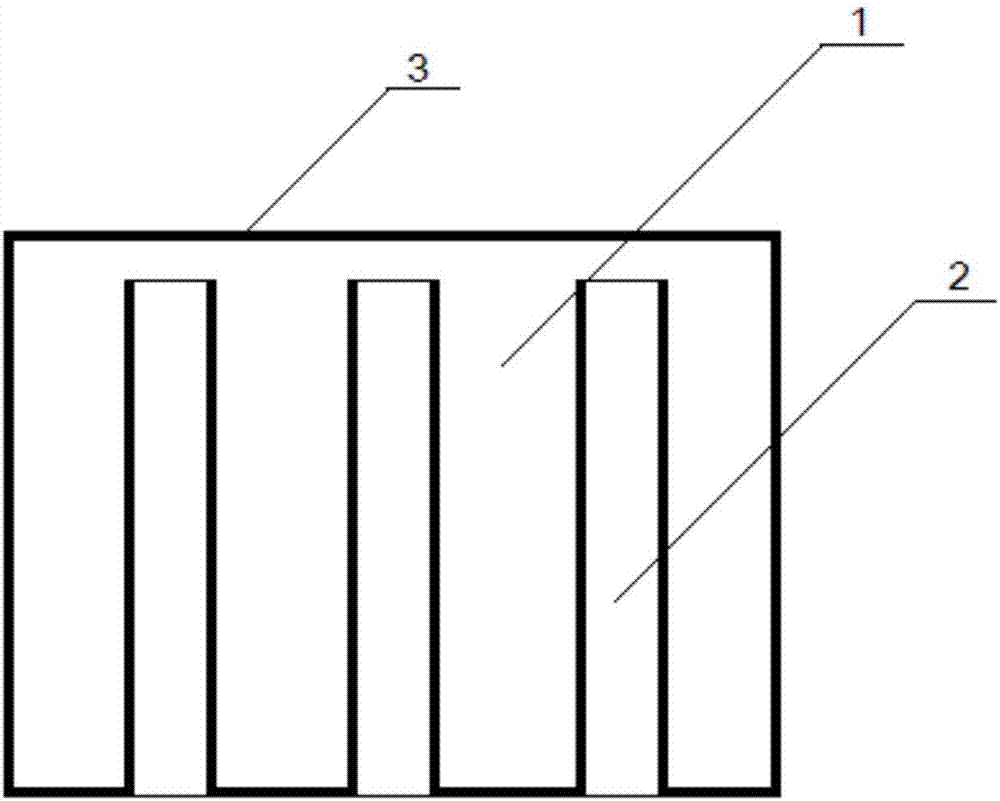

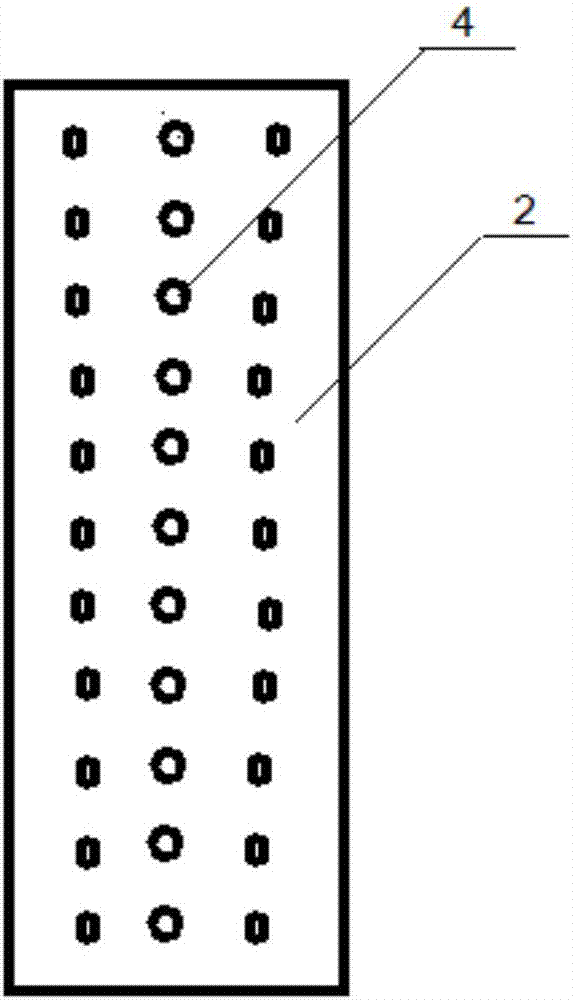

[0020] Embodiment 1: A kind of tea fermenter with air duct, the fermenter body 1 is cylindrical, the top of the fermenter body 1 is provided with an airtight tank cover 3, and the fermenter body 1 is provided with a tank communicating with the bottom of the fermenter body 1. Air guide tube 2, the air guide tube 2 is a hollow cylinder, the hollow cylindrical inner space of the air guide tube 2 leads to the outer space at the bottom, and the air guide tube 2 is provided with a hole 4 for guiding air.

Embodiment 2

[0021] Embodiment 2: A kind of tea fermenter with air duct, the fermenter body 1 is cylindrical, the top of the fermenter body 1 is provided with an airtight tank cover 3, and the fermenter body 1 is provided with a tank communicating with the bottom of the fermenter body 1. Air guide tube 2, the air guide tube 2 is a hollow cylinder, the hollow cylindrical inner space of the air guide tube 2 leads to the outer space at the bottom, and the air guide tube 2 is provided with a hole 4 for guiding air. The bottom of the air duct 2 is hollow and communicates with the outside.

Embodiment 3

[0022] Embodiment 3: A kind of tea fermenter with ventilation conduit, the fermenter body 1 is cylindrical, and the top of the fermenter body 1 is provided with a closed tank cover 3, and the fermenter body 1 is provided with a tank communicating with the bottom of the fermenter body 1. Air guide tube 2, the air guide tube 2 is a hollow cylinder, the hollow cylindrical inner space of the air guide tube 2 leads to the outer space at the bottom, and the air guide tube 2 is provided with a hole 4 for guiding air. The bottom of the air duct 2 is hollow and communicates with the outside. The fermenter body 1, air duct 2 and tank cover 3 are made of stainless steel.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com