Excellent high-speed energy-saving beating machine

A beater and high-speed technology, applied in beverage preparation devices, household appliances, applications, etc., can solve problems such as poor energy saving effect, slow processing speed, and poor structure, and achieve rigorous structure, low manufacturing cost, and low manufacturing cost. extreme effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

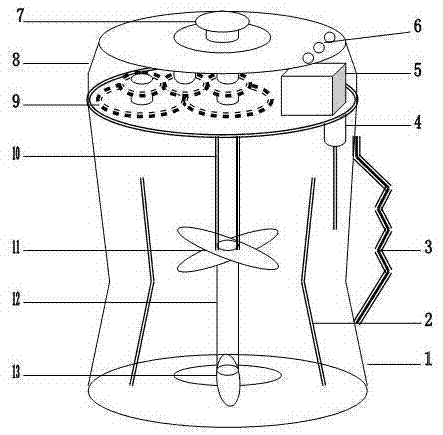

[0018] As shown in the accompanying drawings, the high-quality high-speed energy-saving beater of the present invention includes two parts: an outer body and a device body.

[0019] The outer body includes a barrel body 1, a grinding bar 2, and a handle 3. The barrel body 1 is arranged on the lower part and the outside of the device body and has a thin waist shape, and its function is to support the device body and contain processing materials and coordinate processing. The grinding bar 2 is arranged on the inner side of the barrel body 1, and its function is to block the grinding material and assist the positive folding knife 13 and the reverse folding knife 11 to carry out effective processing. The handle 3 is arranged on the outside of the barrel body and is in a zigzag shape , its role is to pull out the barrel and dump the soybean milk, the device body includes a detection rod 4, a controller 5, a button 6, a handle 7, a control cover 8, a driving gear 9, a reverse drive l...

example

[0025] Put the high-quality high-speed energy-saving beater of the present invention in an appropriate position, uncover the control cover 8, put the required processing materials into the barrel body 1, insert the wire plug into the power socket connected to the controller 5 on the side of the control cover 8, And press the relevant buttons such as soybean milk or porridge to be processed. When the heating of the processing material reaches the predetermined value and the detection rod 4 conducts an early warning, the controller 5 starts the drive gear 9, and the drive gear 9 drives the positive drive rod 12 and the reverse drive rod 12 respectively. Stacking knife 11, while driving forward driving rod 12 and reverse driving rod 10 respectively drive forward stacking knife 13 and reverse stacking knife 11 to carry out reverse multi-layer rapid three-dimensional crushing process on the processing material, while barrel body 1 thin waist and grinding rod 2, etc. Assist the devic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com