Dissection type 3D printing net-shaped skull patch

A 3D printing, anatomical technology, applied in the fields of skull, bone implants, medical science, etc., can solve the problems of high incidence of intracranial effusion, poor anatomical matching, difficult puncture and extraction, etc. Incidence of effusion and infection, effect of promoting repair and healing, reducing the risk of cutting injury

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0052] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

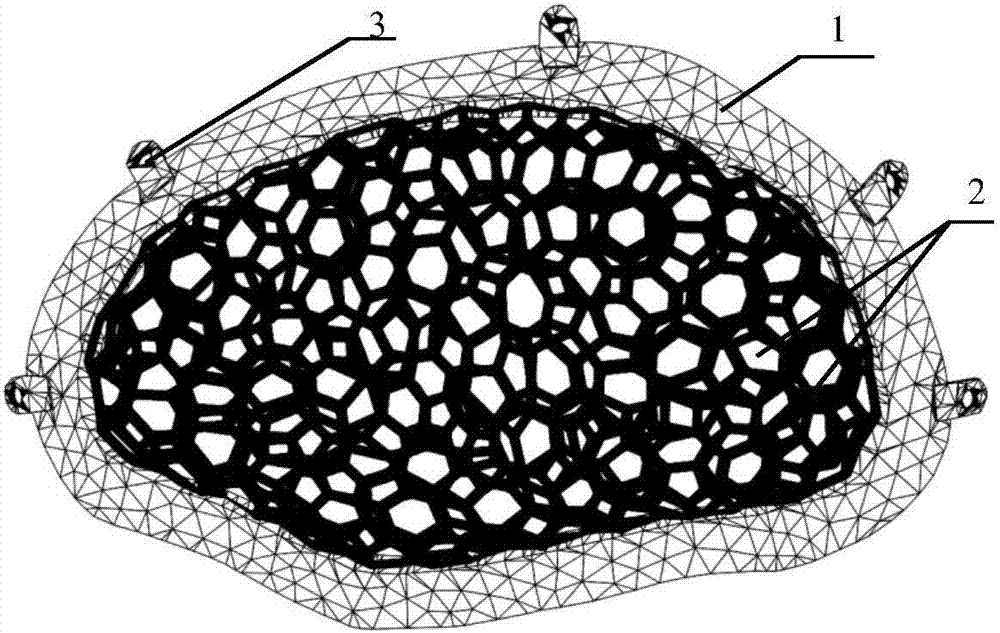

[0053] Figure 1 to Figure 6 They are schematic diagrams of the six structures of the anatomical 3D printed mesh skull patch of the present invention.

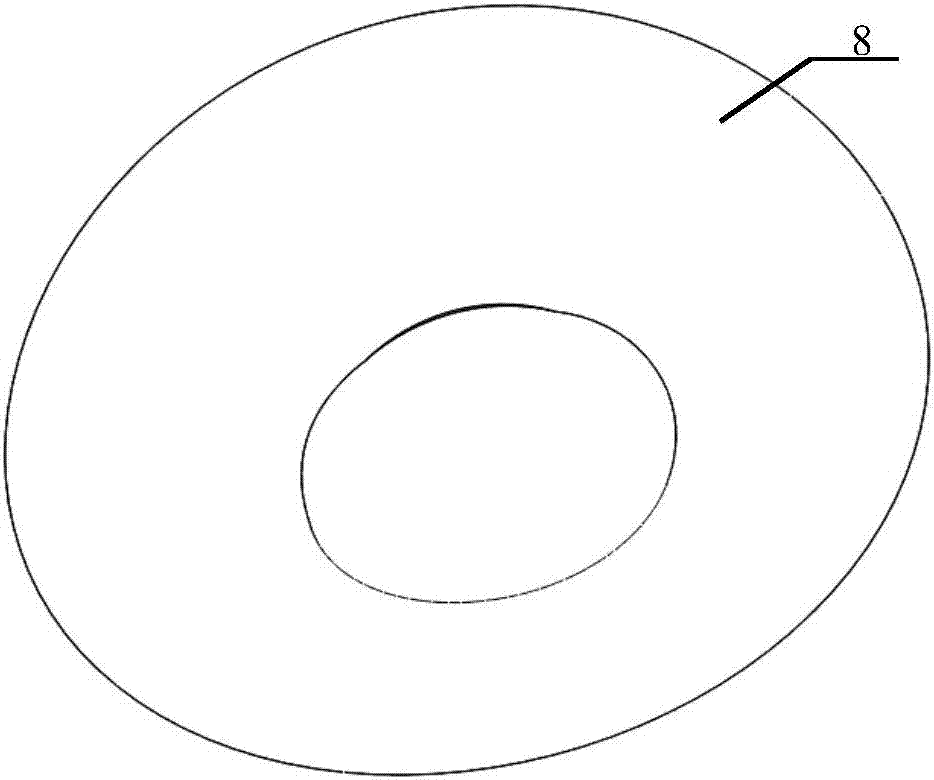

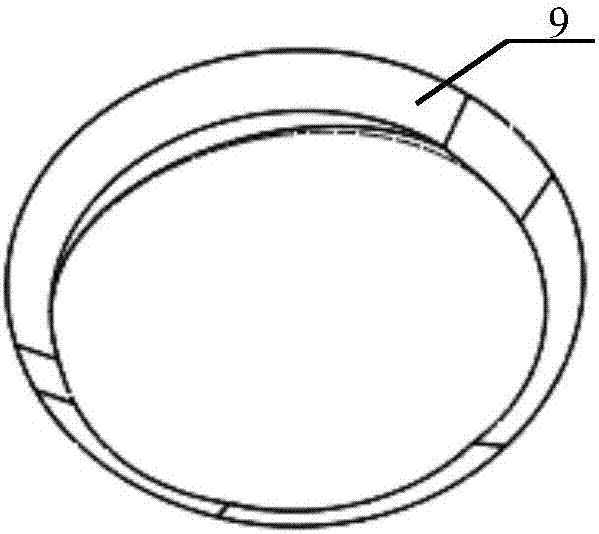

[0054] Such as figure 1 As shown, the anatomical 3D printed mesh skull patch includes a skull patch edge 1 and a skull patch mesh structure 2 that match the brain injury site; the skull patch edge 1 is a non-porous belt Tentacle structure, tentacle 3 with counterbore 7, such as Figure 13 As shown, the cross-sectional shape of the counterbore 7 is a trapezoidal structure; the mesh structure 2 of the skull patch is composed of a beam structure 4 (such as Figures 9 to 11 Shown) is a continuous mesh formed by random interweaving of multi-layer meshes.

[0055] Such as figure 2 As shown, the anatomical 3D printed mesh skull patch includes a skull patch edge 1 and a skull patch mesh structure...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com