Method for producing truck push rod support through iron mold sand coating casing

A technology of sand-covered iron casting and production methods, which is applied to casting molding equipment, casting molds, cores, etc., can solve problems such as poor surface quality, unguaranteed overall mechanical properties, and loose organization, and achieve low manufacturing costs , Eliminate the defects of subcutaneous stomata, the effect of short production cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The specific implementation of the present invention is described in detail below, but it does not constitute a limitation to the protection scope of the claims of the present invention.

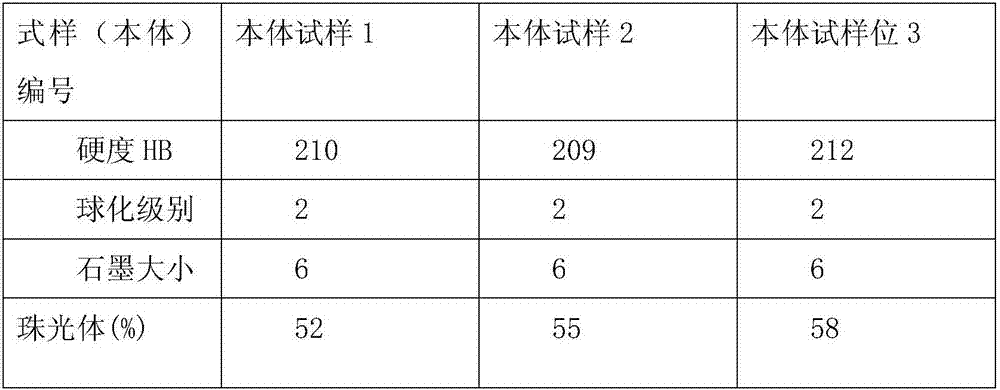

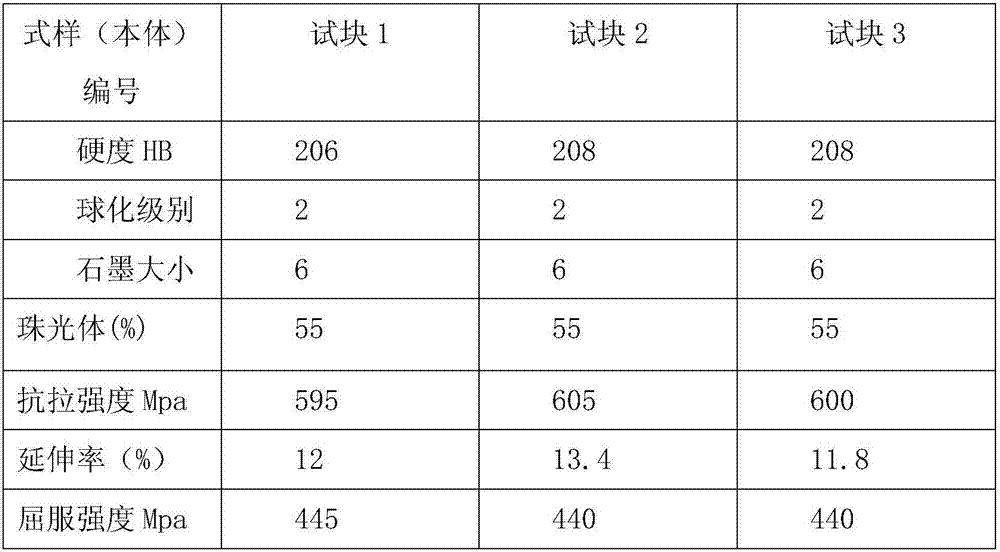

[0028] The iron mold sand-covered casting process of the present invention is to use the iron mold to increase the cooling rate of molten iron in the casting process, refine the structure, and improve the thickness of the truck push rod bracket to ensure the thicker parts of the body or thicker bosses under the condition of uneven wall thickness. Tissue compactness of tazi. Under the same composition of smelted molten iron, using the iron mold sand casting process to produce the body can obtain higher tensile strength, hardness and better graphite shape and graphite size grade than the sand casting process, and the stable pearlite is more than 50%. Most importantly, truck push rod bracket elongation has been improved.

[0029] The iron mold sand-coated casting process of the truck pu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com