Finish machining assisting device for gear starting inner hole of steam turbine high pressure cylinder and finish machining method

An auxiliary device and high-pressure cylinder technology, which is applied in the direction of mechanical measuring devices, adopting mechanical devices, measuring devices, etc., can solve the problems of large errors, high costs, and low measurement accuracy, and achieve reduced measurement errors, low manufacturing costs, and clamping The effect of convenient installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

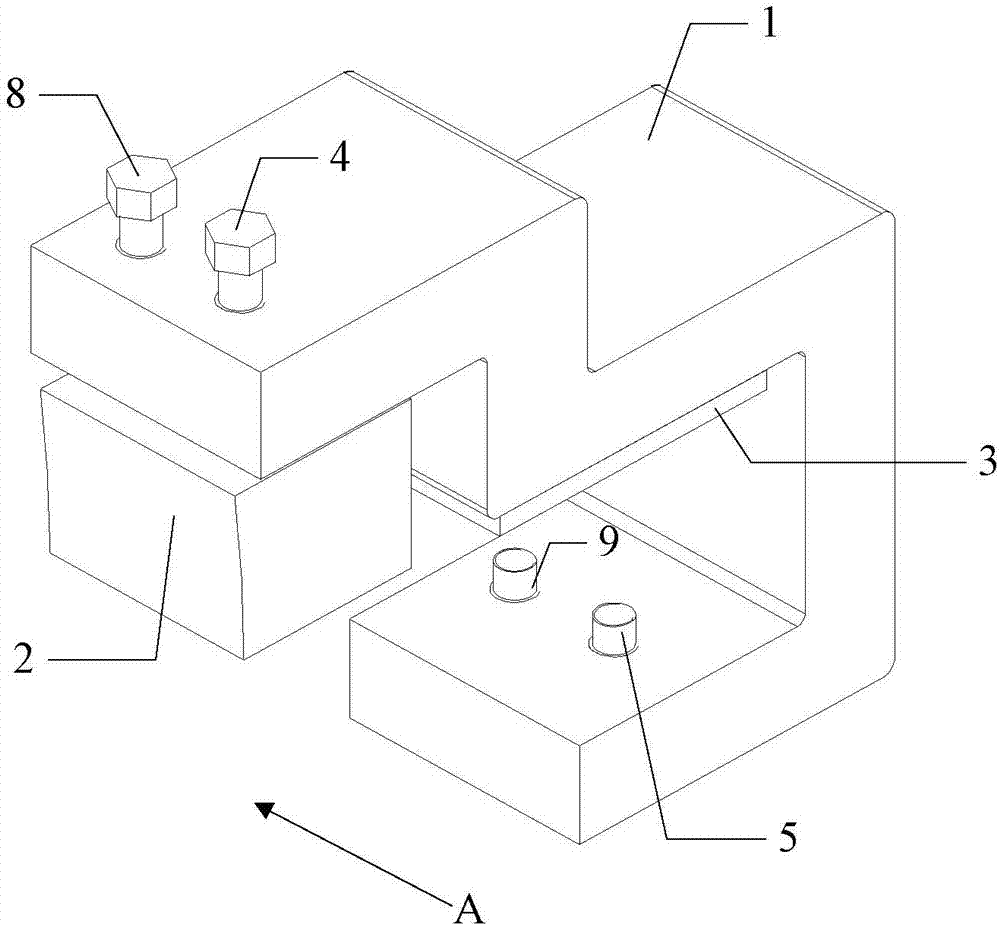

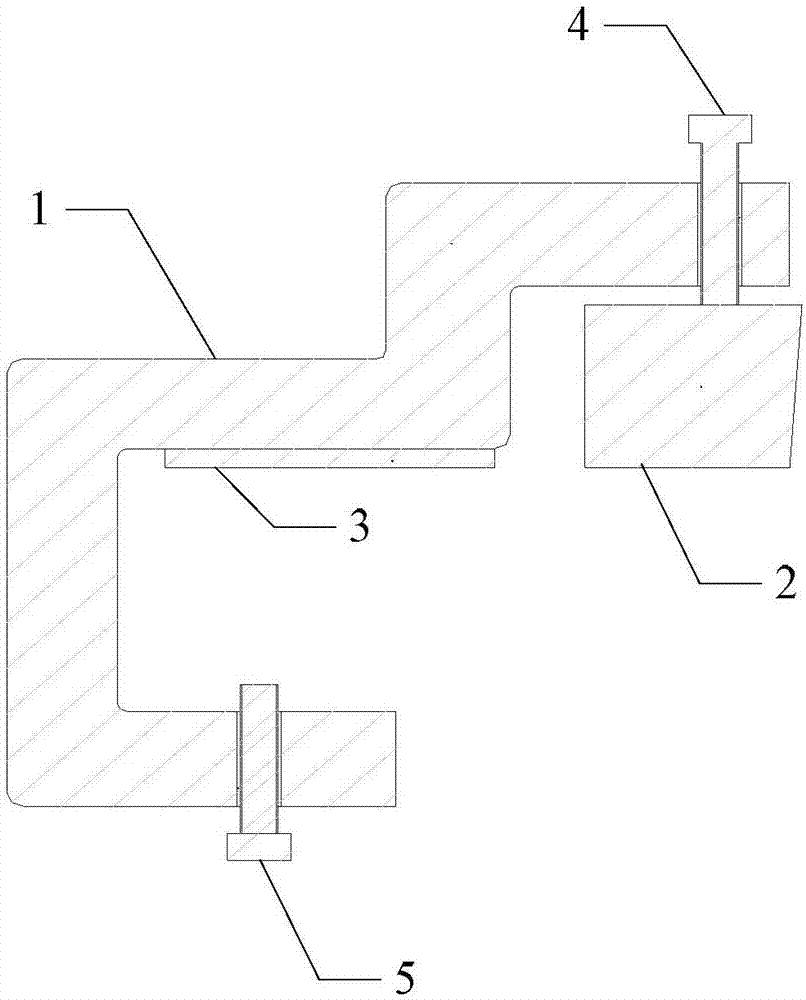

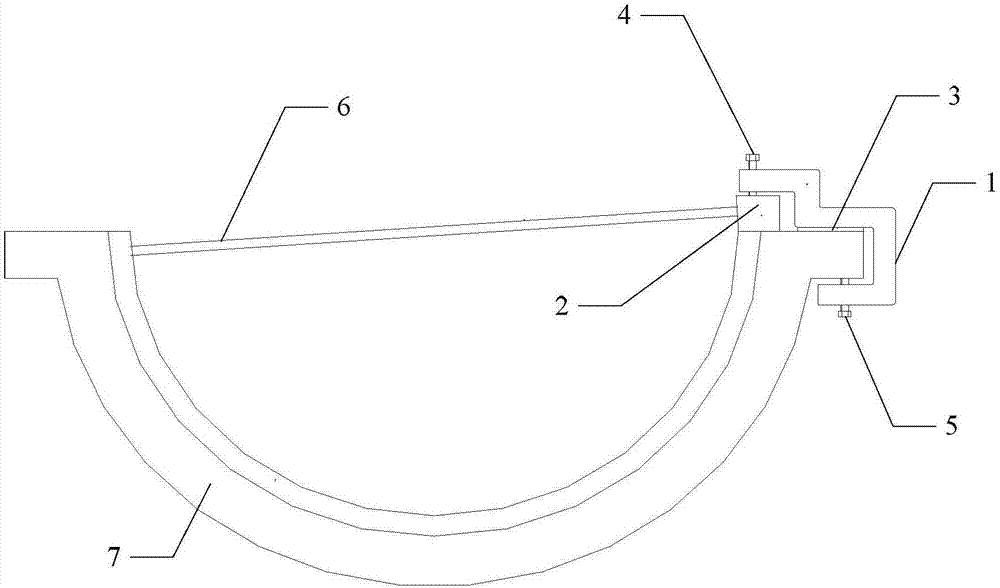

[0018] Specific implementation mode one: combine figure 1 and figure 2 Describe this embodiment, a steam turbine high-pressure cylinder gear-shifting inner hole finish machining auxiliary device described in this embodiment includes a clamping frame 1, a measuring briquetting block 2, a No. 1 bolt 4 and a No. 2 bolt 5;

[0019] The clamping frame 1 is provided with an opening slot, the upper part of the opening slot is provided with a No. 1 bolt through hole, and the lower part of the opening slot is provided with a No. 2 bolt through hole; the clamping frame 1 is used for conveniently fixing the measuring pressure block 2;

[0020] The No. 1 bolt 4 is used to fix the measuring briquetting block 2 through the No. 1 bolt through hole; and the measuring briquetting block 2 is located at the opening inner hole of the high-pressure cylinder, and the measuring briquetting block 2 is used to increase the processing of the opening inner hole of the high-pressure cylinder Range, so ...

specific Embodiment approach 2

[0023] Specific embodiment 2: This embodiment is to further limit the auxiliary device for finishing the inner hole of a high-pressure cylinder of a steam turbine described in the specific embodiment 1. In this embodiment, it also includes a gasket 3, and the gasket 3 Arranged between the clamping frame 1 and the horizontal mid-section of the high-pressure cylinder 7, the gasket 3 is used to protect the horizontal mid-section of the shift inner hole of the high-pressure cylinder.

[0024] In this embodiment, the gasket 3 is made of copper material, and the copper gasket 3 can better protect the horizontal split surface of the inner hole of the high pressure cylinder.

specific Embodiment approach 3

[0025] Specific implementation mode three: combination figure 1 Describe this embodiment, this embodiment is to further limit a kind of steam turbine high-pressure cylinder gear opening inner hole finishing auxiliary device described in the first embodiment, in this embodiment, measure the material of the briquetting block 2 and the high-pressure cylinder 7 The material is the same.

[0026] In this embodiment, the material of the measuring briquetting block 2 and the high-pressure cylinder 7 are the same, and the deformation of the measuring briquetting block 2 and the high-pressure cylinder 7 can be guaranteed to be the same during the processing, so that the measurement result is more accurate. At the same time, the thickness of the measuring briquetting block 2 is greater than 50 mm, so that the processing range of the opening inner hole is controlled within a reasonable range.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com