Card bearing platform applied to intelligent card slot milling machine and intelligent card slot milling machine

A card and card milling technology, which is applied in the field of smart card manufacturing, can solve the problems of unable to clamp the card and accurately clamp the card, and achieve the effect of improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

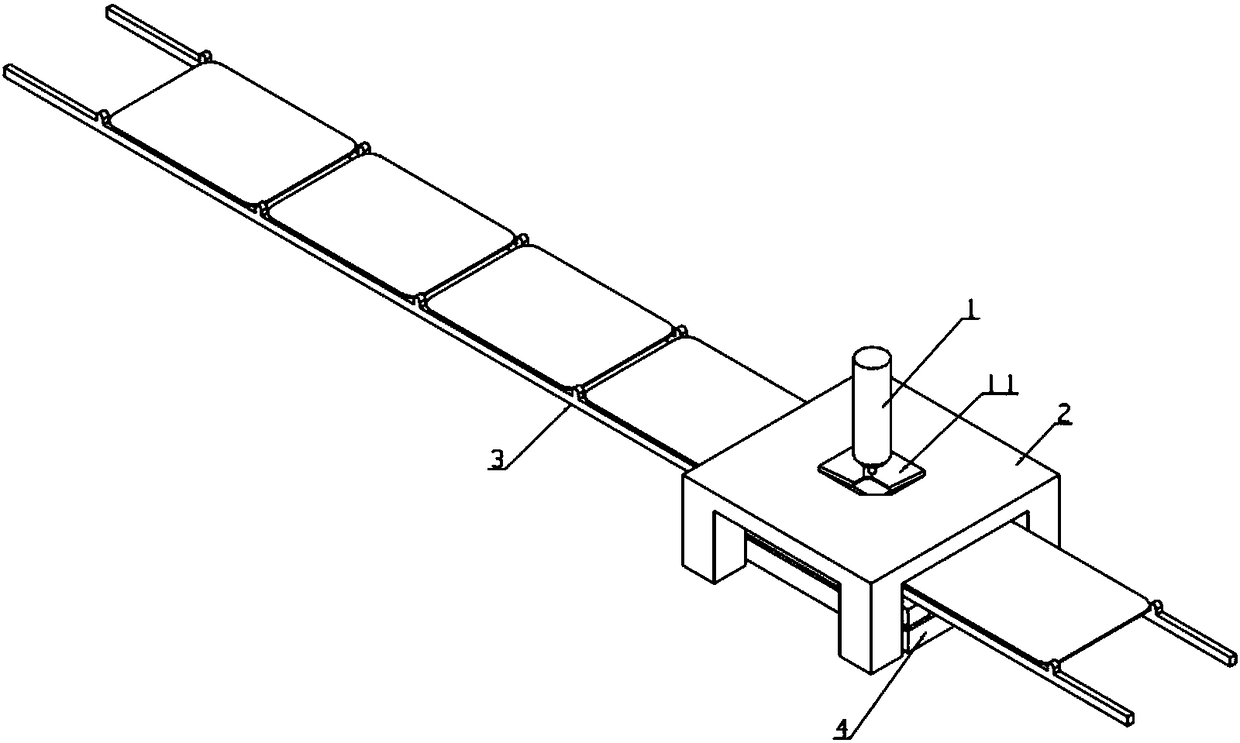

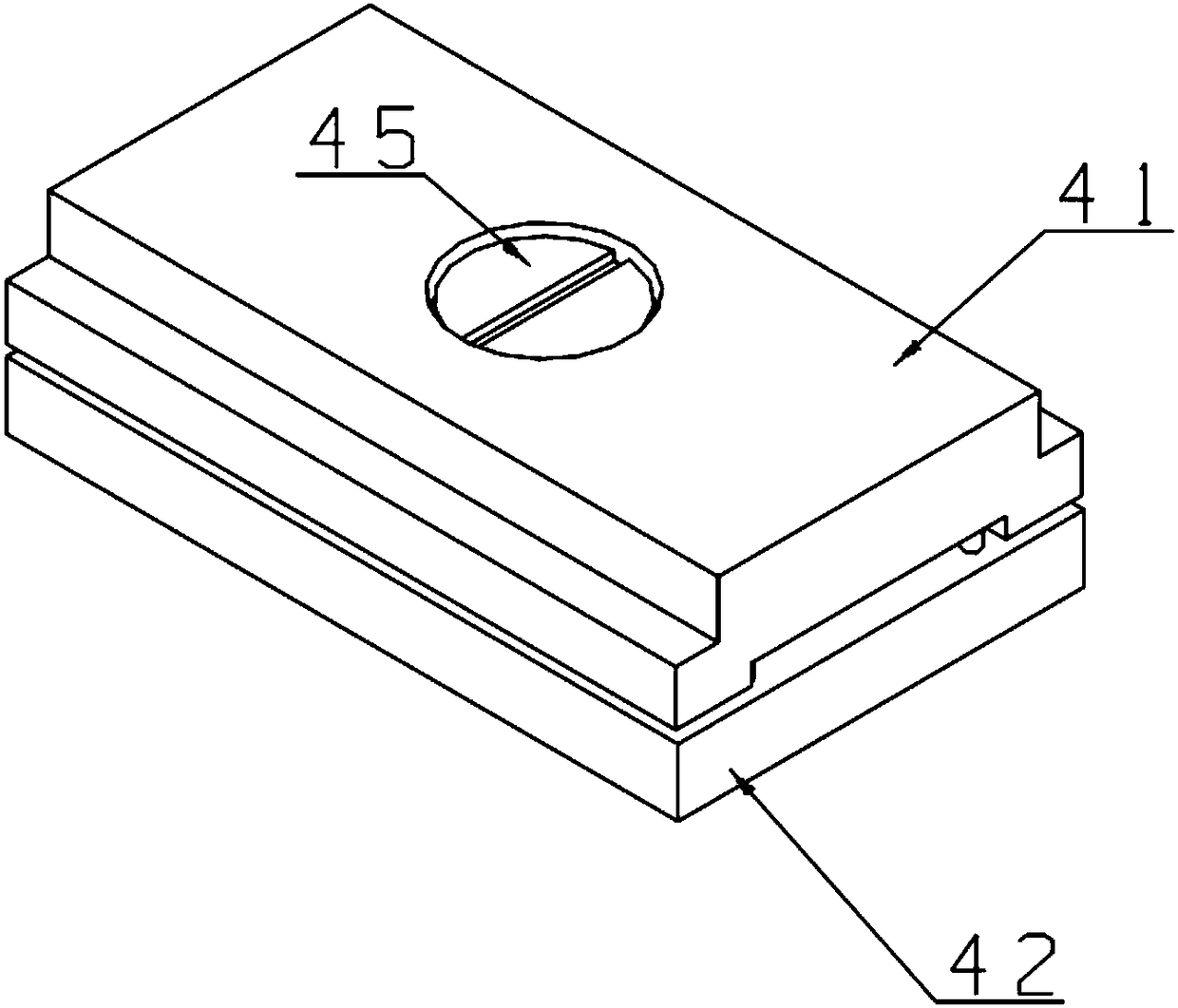

[0047] Such as Figure 2 to Figure 4 As shown, it is Embodiment 1 of the present invention. This embodiment provides a card support platform 4 applied to a smart card slot milling machine, which is used to be installed on the smart card slot milling machine and cooperate with the upper pressing plate 2 to press the cards. .

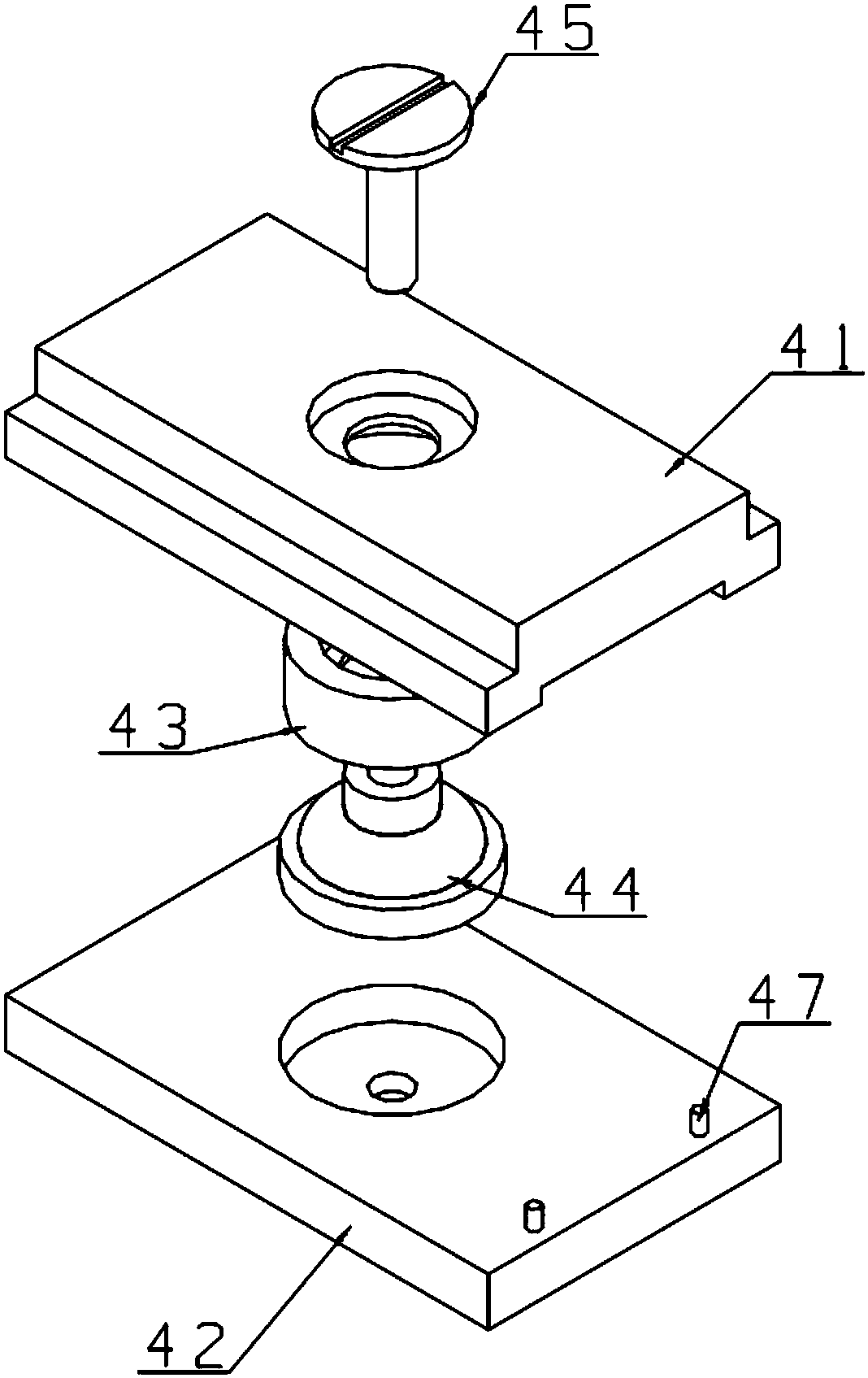

[0048] This embodiment includes a supporting plate 41, a base 42 and a universal swing mechanism. The pallet 41 has an upper surface for placing cards; the base 42 is placed under the pallet 41; there is a gap between the base 42 and the pallet 41, and the pallet 41 and the base 42 are connected by a universal swing mechanism .

[0049] When milling the card slot, when the card enters between the upper platen 2 and the supporting platform 4 driven by the stepping guide rail 3, the supporting platform 4 rises, and the upper surface of the supporting plate 41 and the lower surface of the upper platen 2 are used to move the card. The surface presses the c...

Embodiment 2

[0059] Such as Figure 5 Shown is Embodiment 2 of the present invention. This embodiment also discloses a card support platform 4 applied to a smart card slot milling machine, which is used to be installed on the smart card slot milling machine and cooperate with the upper pressing plate 2 to press the cards. .

[0060] This embodiment has the same parts as Embodiment 1, the difference is that in this embodiment, the ball portion 44 is mounted on the supporting plate 41, the bowl portion 43 is mounted on the base 42, and the limiting elements 45 pass through in turn The base 42 , the bowl portion 43 , and the ball portion 44 are screwed to the support plate 41 , and the pressing portion 451 of the limiting element 45 presses the ball portion 44 onto the support plate 41 . The limiting element 45 in this embodiment is also a bolt, and there is a gap between the head of the bolt and the base 42 . Since the present invention has the same components and structures as in Embodime...

Embodiment 3

[0062] Such as Image 6 Shown is Embodiment 3 of the present invention. This embodiment also discloses a card supporting platform 4 applied to a smart card slot milling machine, which is used to be installed on the smart card slot milling machine and cooperate with the upper pressing plate 2 to press the cards. .

[0063] This embodiment has the same parts as Embodiment 1, the difference is that in this embodiment, the ball portion 44 is mounted on the supporting plate 41, the bowl portion 43 is mounted on the base 42, and the limiting elements 45 pass through in turn The supporting plate 41 , the ball portion 44 , and the bowl portion 43 are screwed to the base 42 , and the pressing portion 451 of the limiting element 45 presses the bowl portion 43 onto the base 42 . The limiting element 45 in this embodiment is also a bolt, and there is a gap between the head of the bolt and the base 42 . Another difference is that the pressing portion 451 in this embodiment is a flange di...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com