Patents

Literature

110results about How to "Reduce elevation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

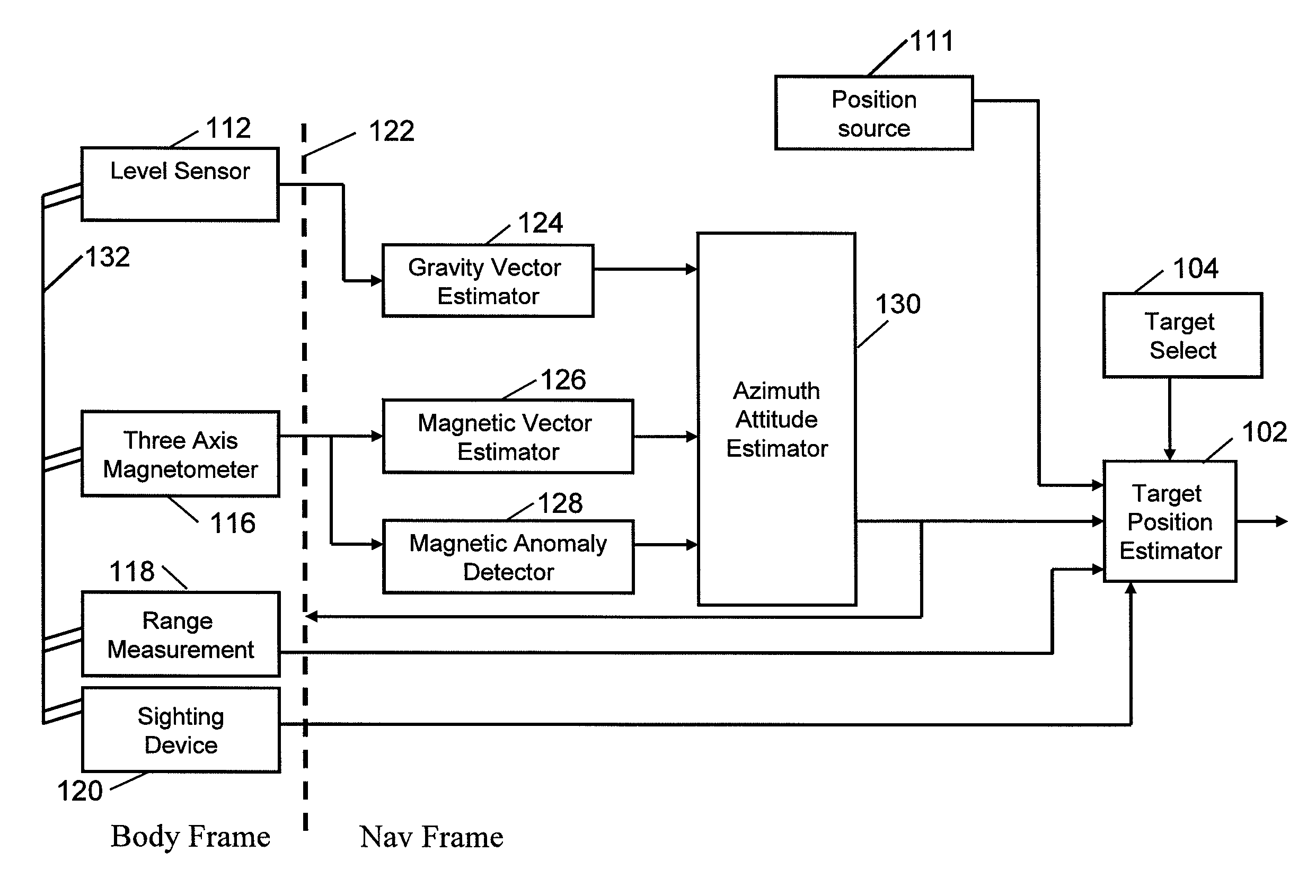

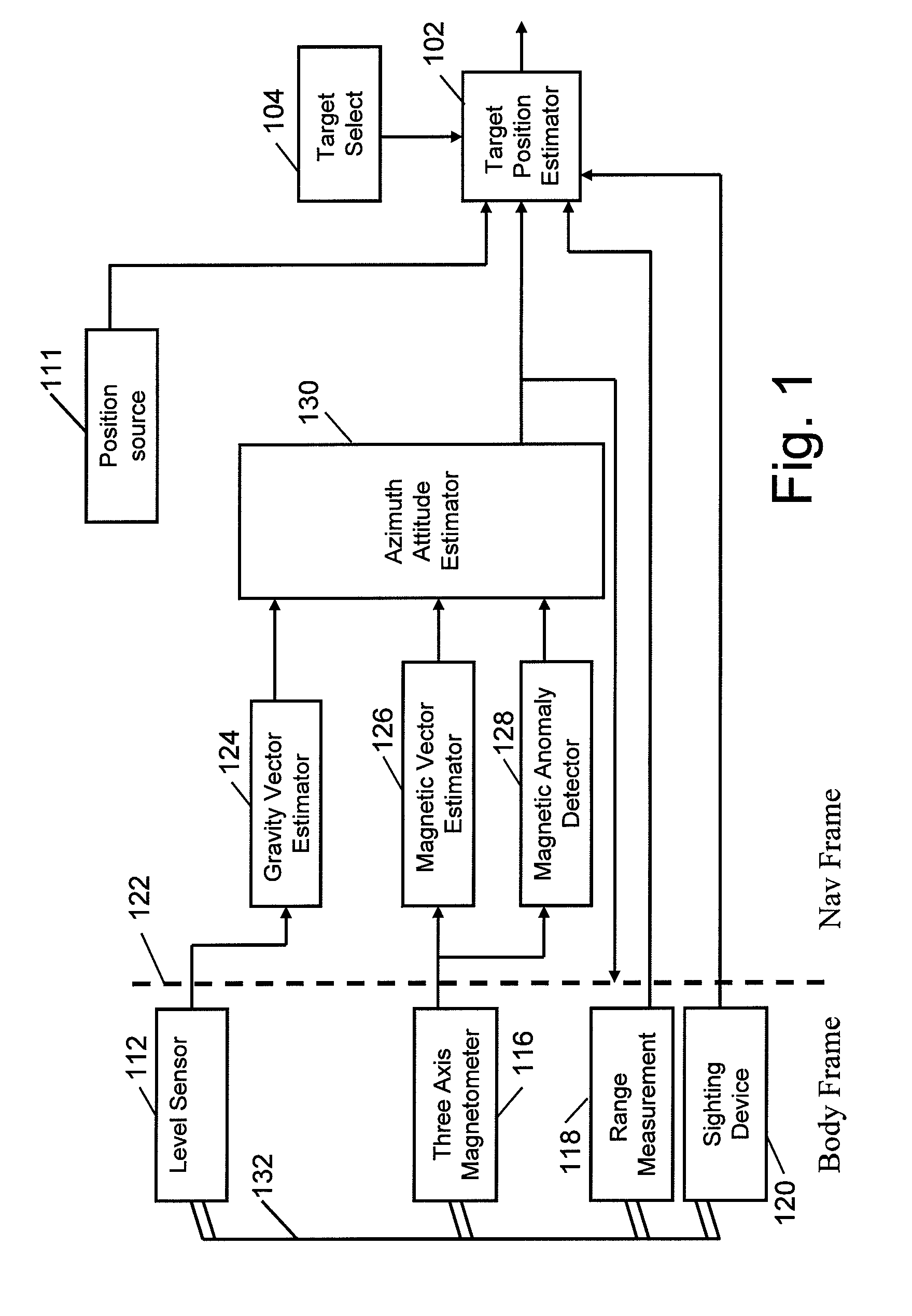

Magnetically stabilized forward observation platform

ActiveUS8275544B1Improved rapid initializationImprove operationDigital computer detailsNavigation by speed/acceleration measurementsMagnetic stabilizationGps receiver

A system and method for determining a position of a remote object comprising inertial sensors and three axis magnetic sensor, together with a target sighting device aligned with the observation platform to determine a target line of sight and a target range finder to determine a distance to the target along the line of sight. A GPS receiver may be included for determining an observation platform position and orientation, The three axis magnetic sensor provides both magnetic north and vertical attitude information for improved rapid initialization and operation in motion. Magnetic anomaly information is detected by comparing IMU and magnetic navigation information and by other methods. Target identification may be determined by a human operator and / or by computer. The system may be integrated with a weapon system to use weapon system sights. The system may be networked to provide target location and / or location error information to another identical unit or a command information system.

Owner:GENERAL ATOMICS

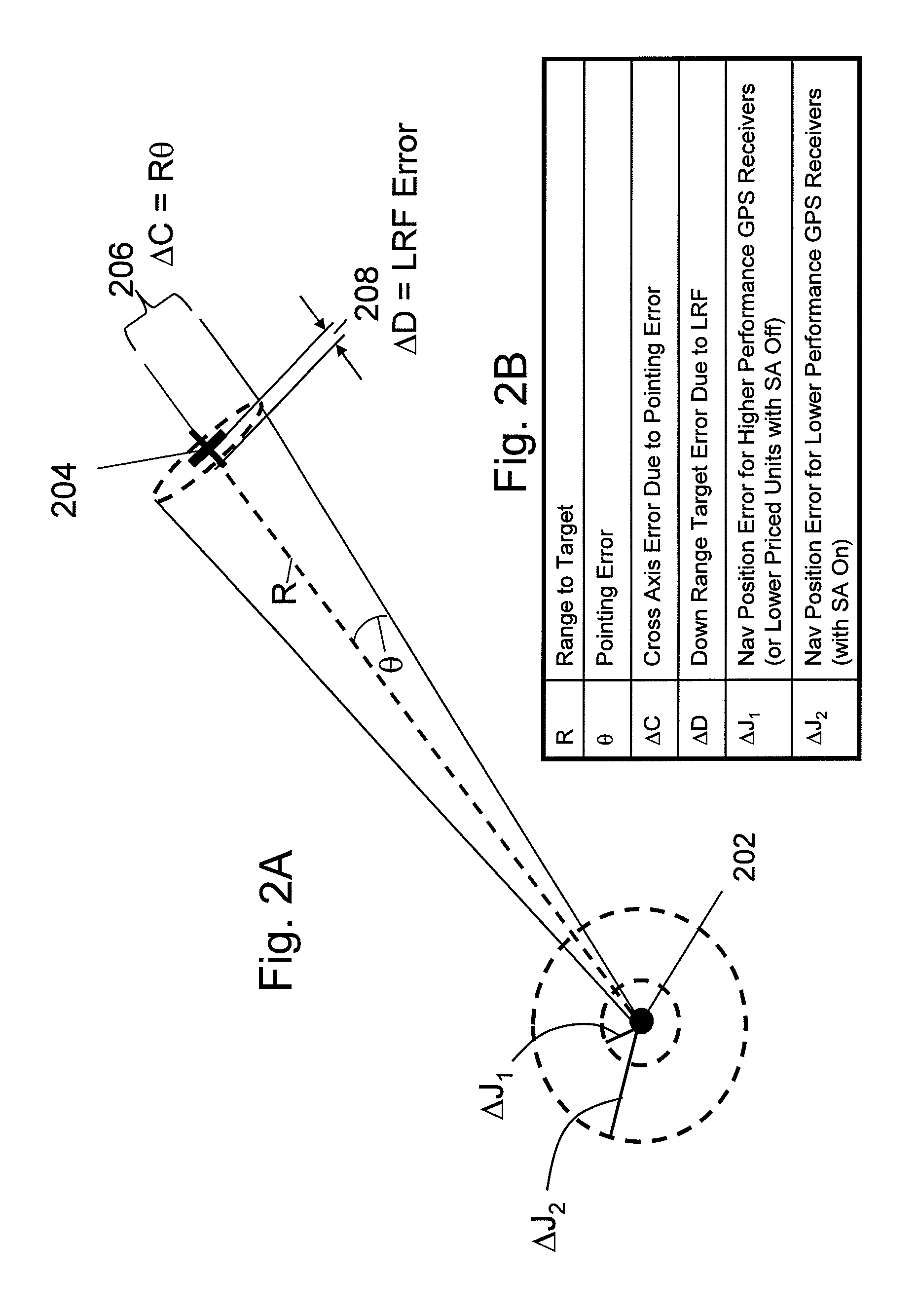

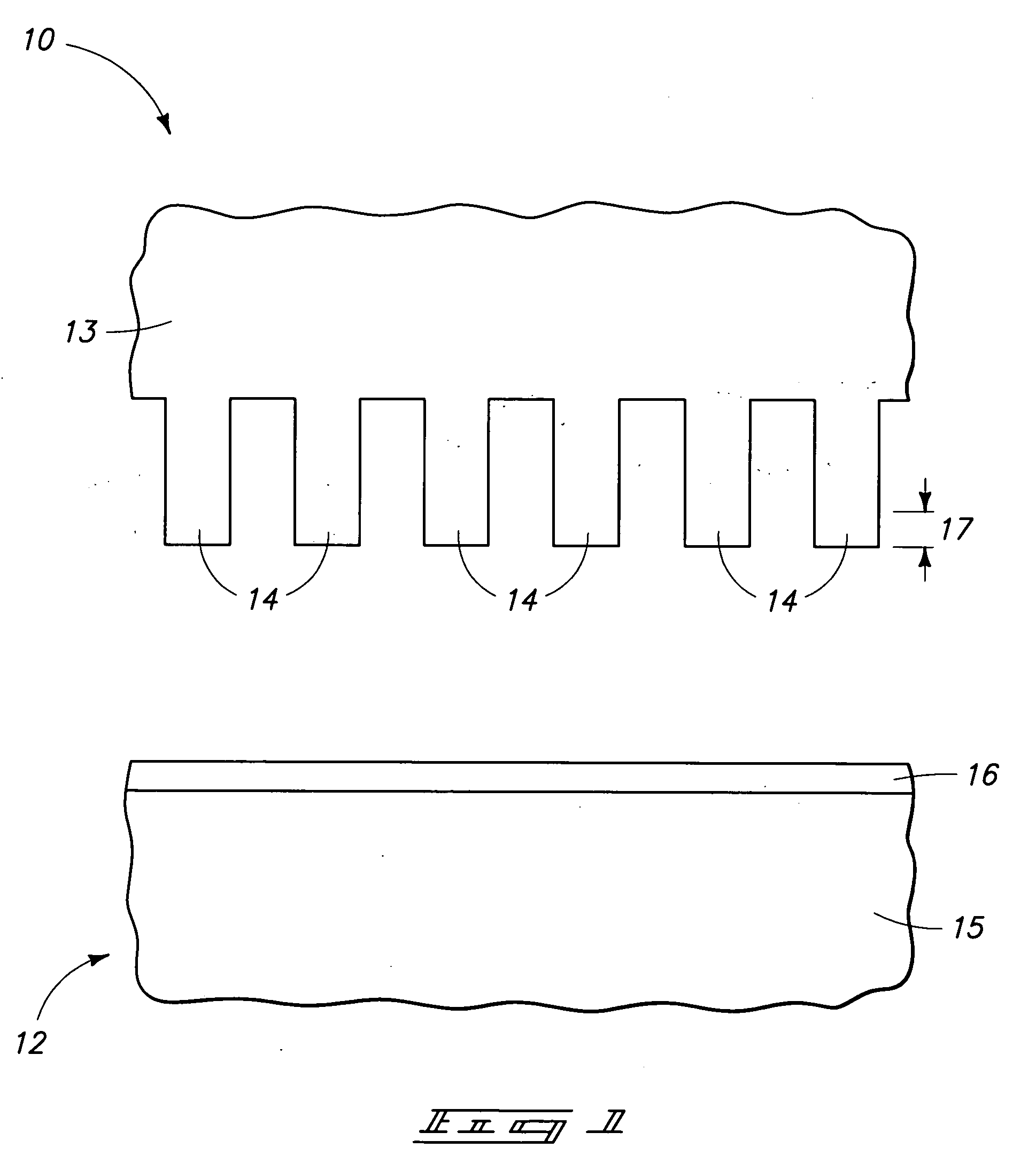

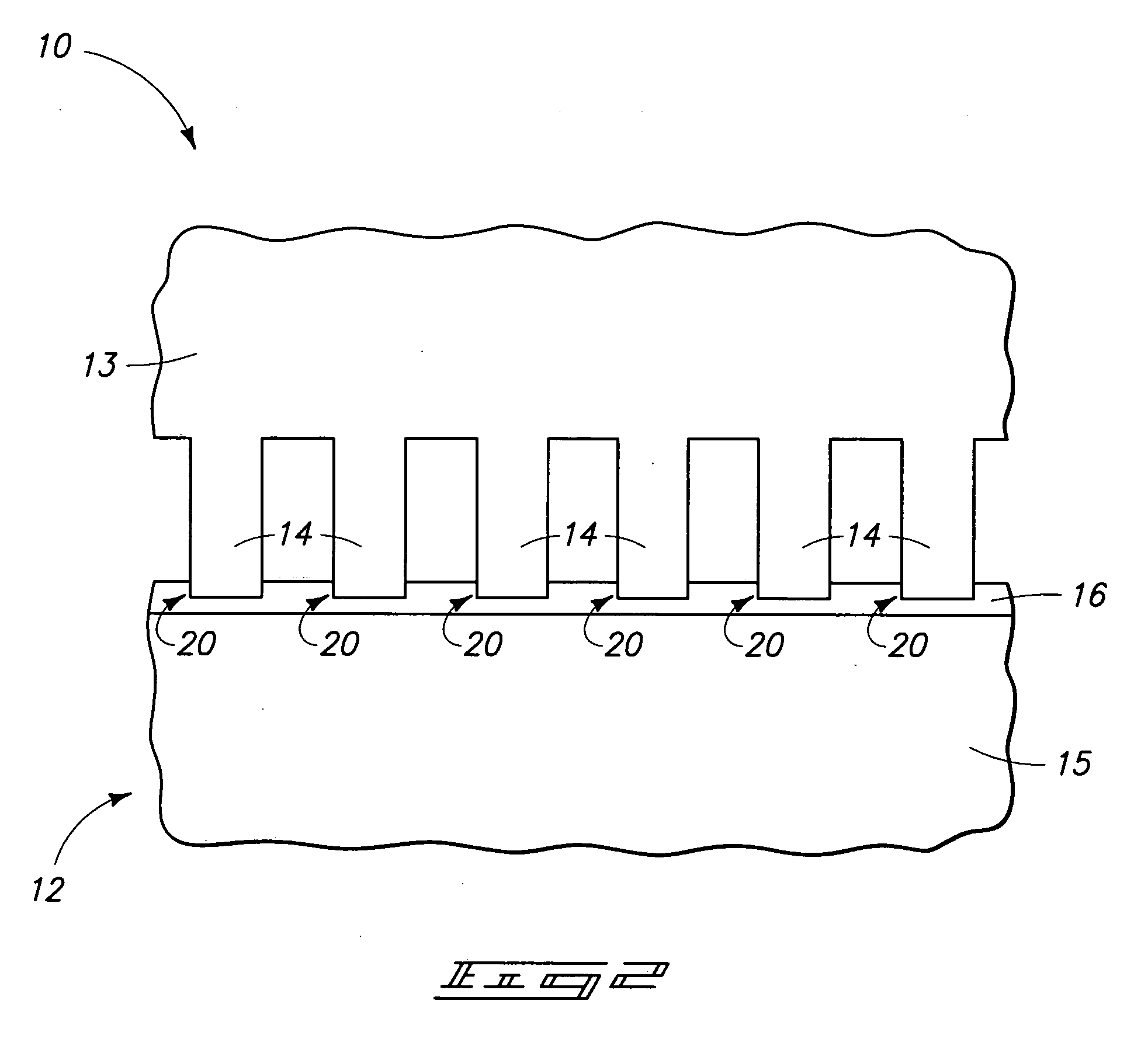

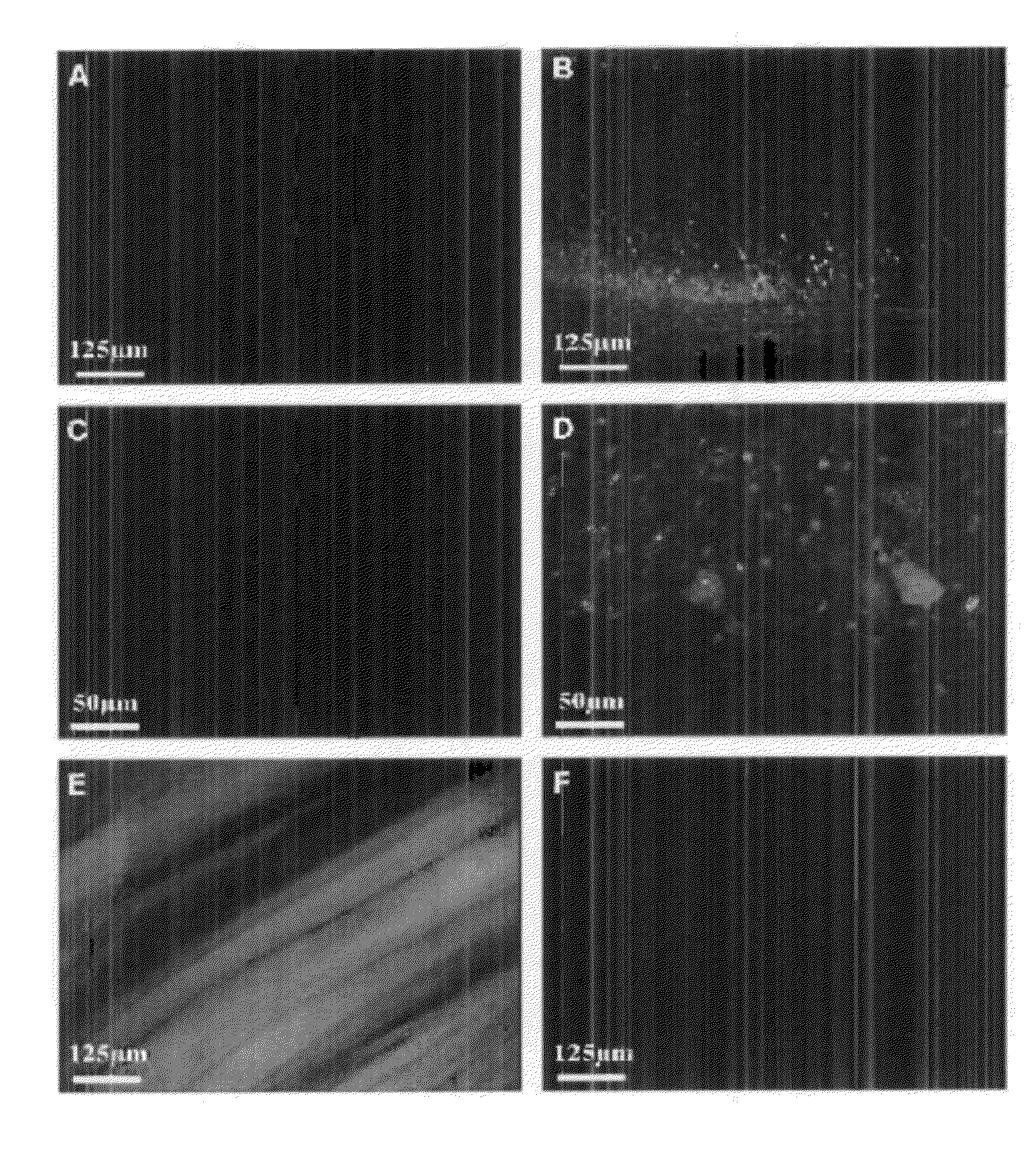

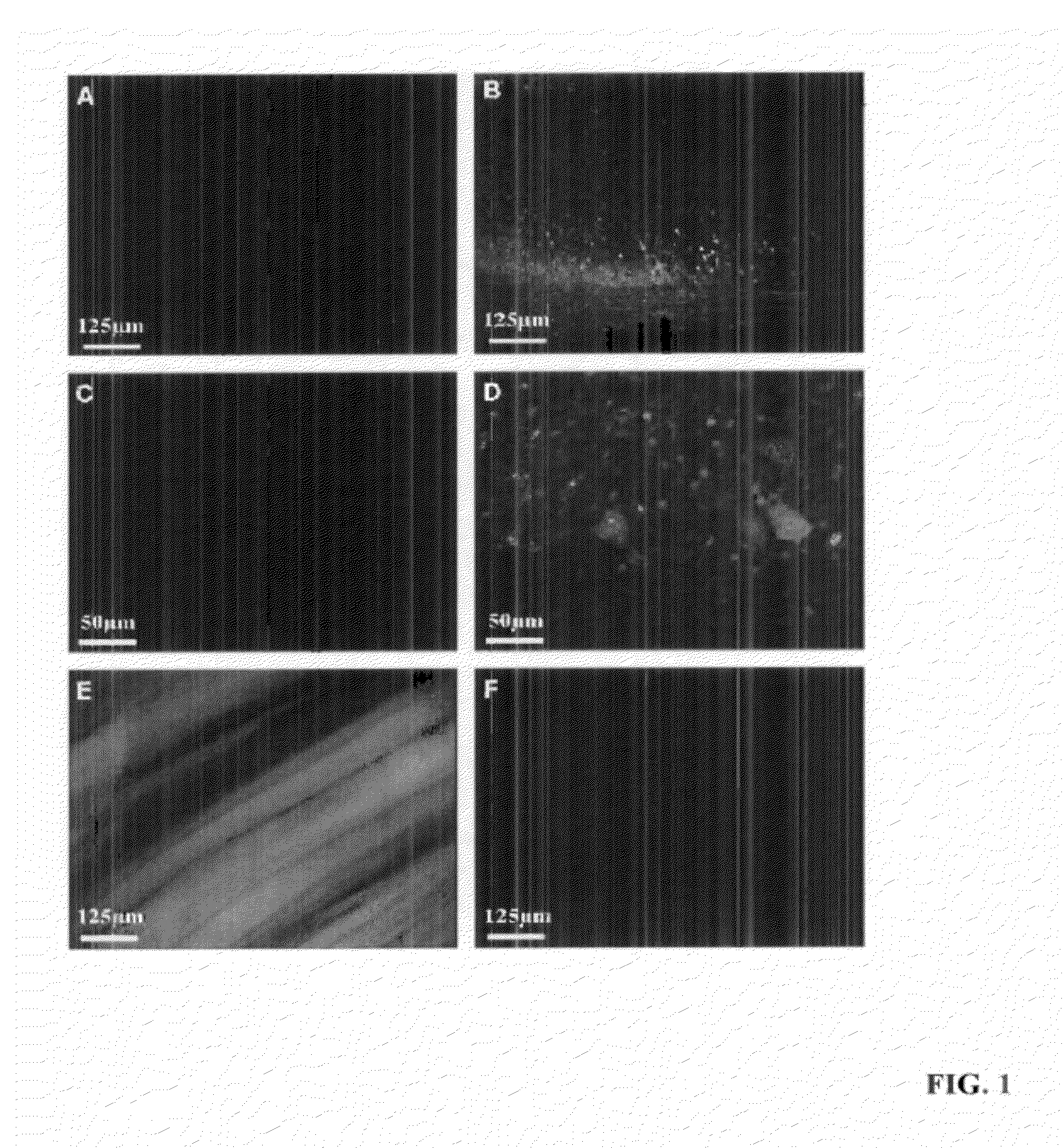

Imprint templates for imprint lithography, and methods of patterning a plurality of substrates

ActiveUS20060255505A1Reduce elevationDecorative surface effectsNanoinformaticsEngineeringLithography

The invention comprises methods of patterning a plurality of substrates, and imprint templates used in imprint lithography. In one implementation, a method of patterning a plurality of substrates includes providing an imprint template having a plurality of spaced features. A first substrate is imprinted with the imprint template effective to form a plurality of recesses into the first substrate from the spaced features. After imprinting the first substrate, an elevationally outermost portion of the spaced features is removed effective to reduce elevation of the spaced features. After the removing, a second substrate is imprinted with the imprint template using the elevation-reduced spaced features effective to form a plurality of recesses into the second substrate from the elevation-reduced spaced features. Other aspects and implementations are contemplated.

Owner:MICRON TECH INC

Standpipe distributor for short time contact of hydrocarbon compounds with particles

InactiveUS6143253ACompact and convenientSmall and convenientCatalytic crackingFluidised-bed furnacesParticle flowJet flow

An arrangement for the controlled production of an essentially linear array of hydrocarbon feed injection jets reduces required clearances and elevation while facilitating modification of the contacting locating a feed distributor containing a linear array of jets at a standpipe junction point to provide choke point for particle flow control. The flow properties of the extended particle layer are controlled by adjusting the density of the particles above the choke point created by the upper part of the standpipe inside diameter and the top of the distributor. Steam or another fluidization medium may be added to the particles directly above the distributor for this purpose. This invention can also modify the particle or feed injection characteristics by changing the projection of the distributor into the standpipe to adjust the flow area over the choke point and by the use of bottom slides or baffles to change the flow area size and configuration. Location of the distributor at a standpipe junction will also typically allow the placement of the distributor at a lower location in the process which eliminates the need to add vessel height for supplying pressure drop for the particle discharge point. The distributor arrangement also fits compactly into most common standpipe junctions. Thus, the arrangement of this invention solves the problem of inserting an extended array of feed injection points into a fluidized particle contacting process without providing a large amount of clearance or additional vessel height.

Owner:UOP LLC

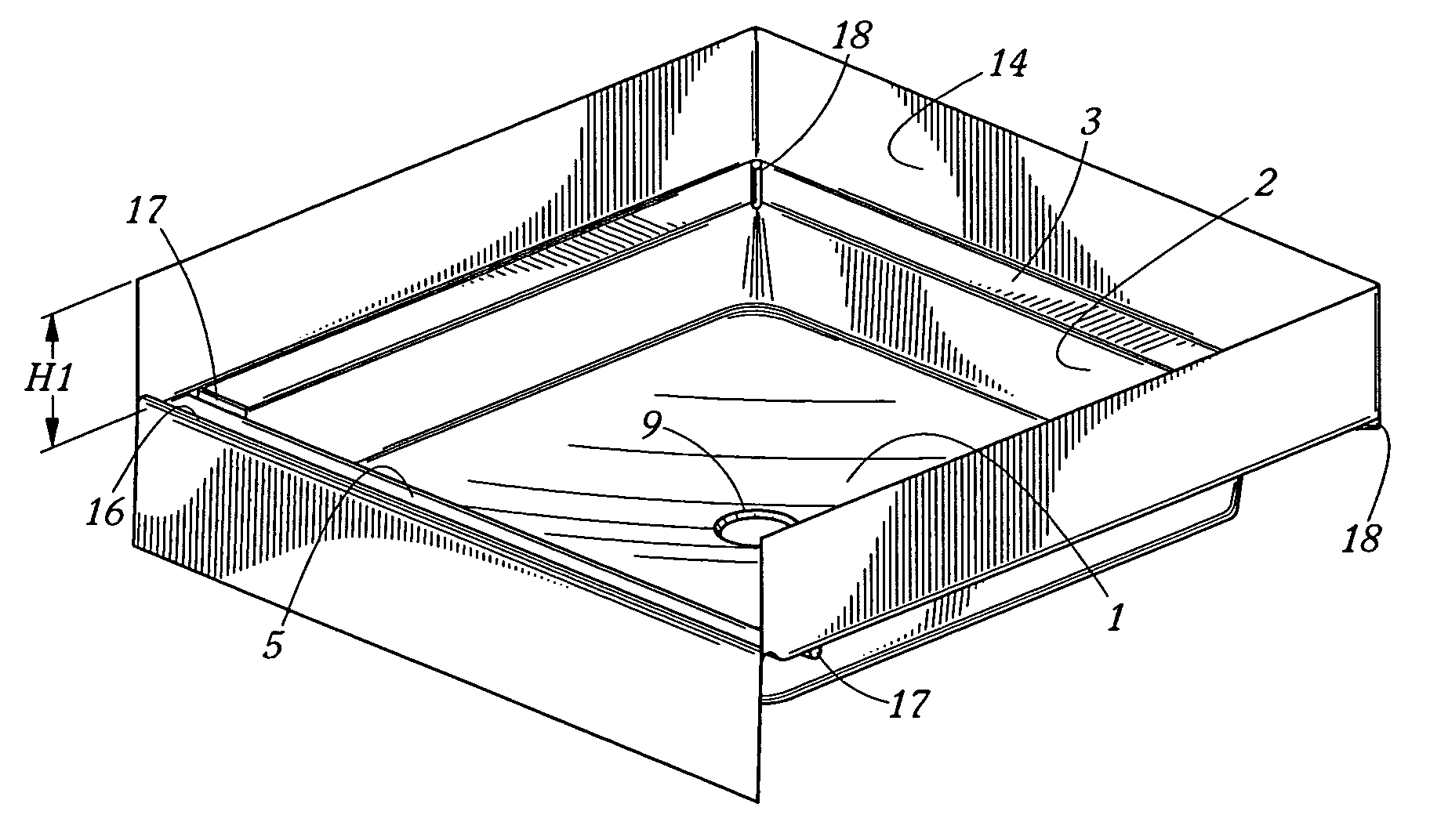

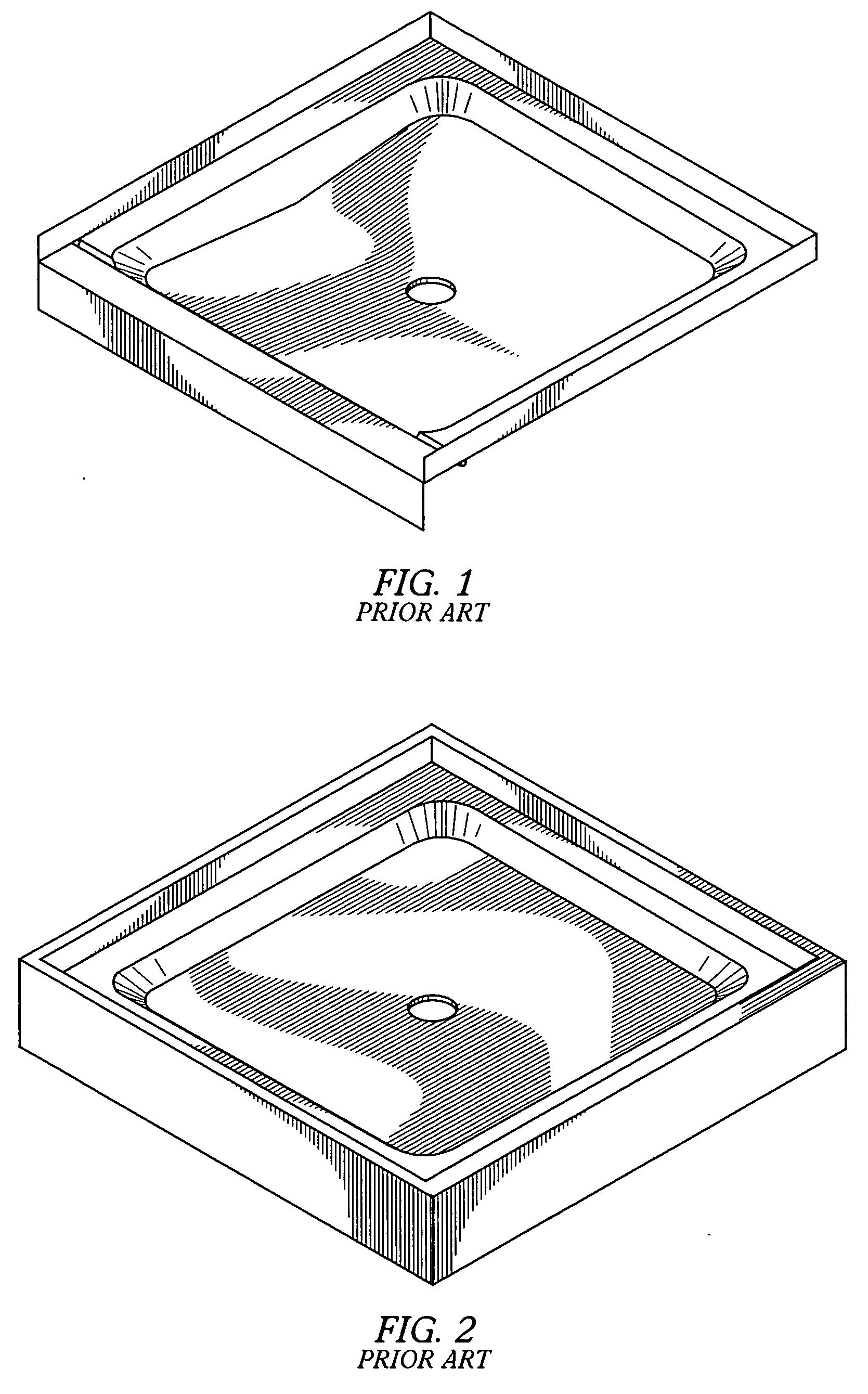

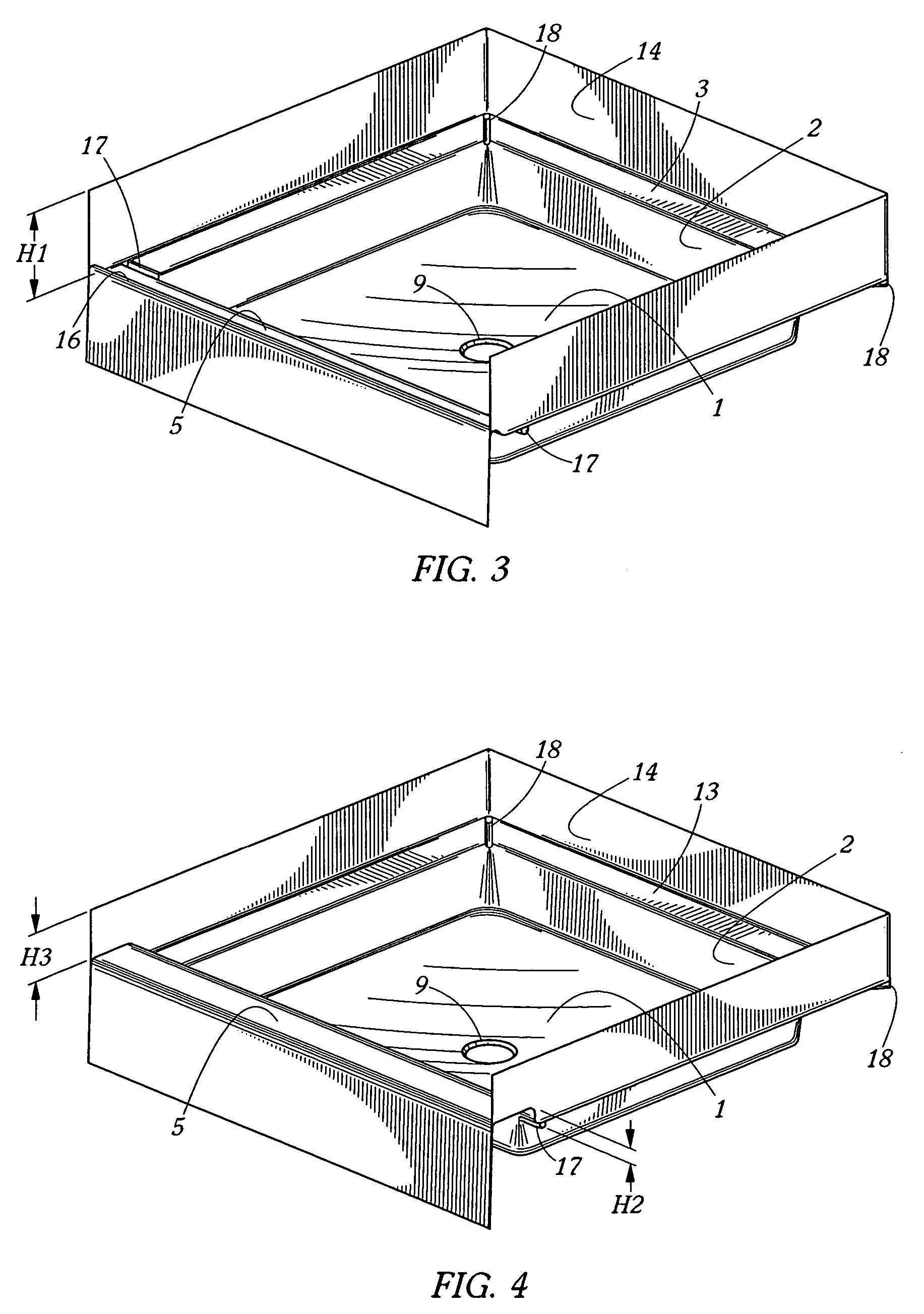

Shower receptor

A shower receptor with improved control of moisture and trapped water comprising one or more of the following improvements: the flange is significantly higher above the threshold than prior art receptors; the threshold is disposed higher than the ledge area where the shower wall materials meet the receptor; weep valleys are provided in the corners of the ledge area and where the ledge meets the threshold; the ledge area comprises multiple steps adapted to meet the subwall and finish wall materials wherein the steps are sloped toward the base and the tile step is lower than the subwall step; a raised curb is provided along the outer edge of the horizontal surface of the threshold, the curb adapted to redirect water that leaks out of the door enclosure back into the shower receptor.

Owner:AQUATIC CALIFORNIA

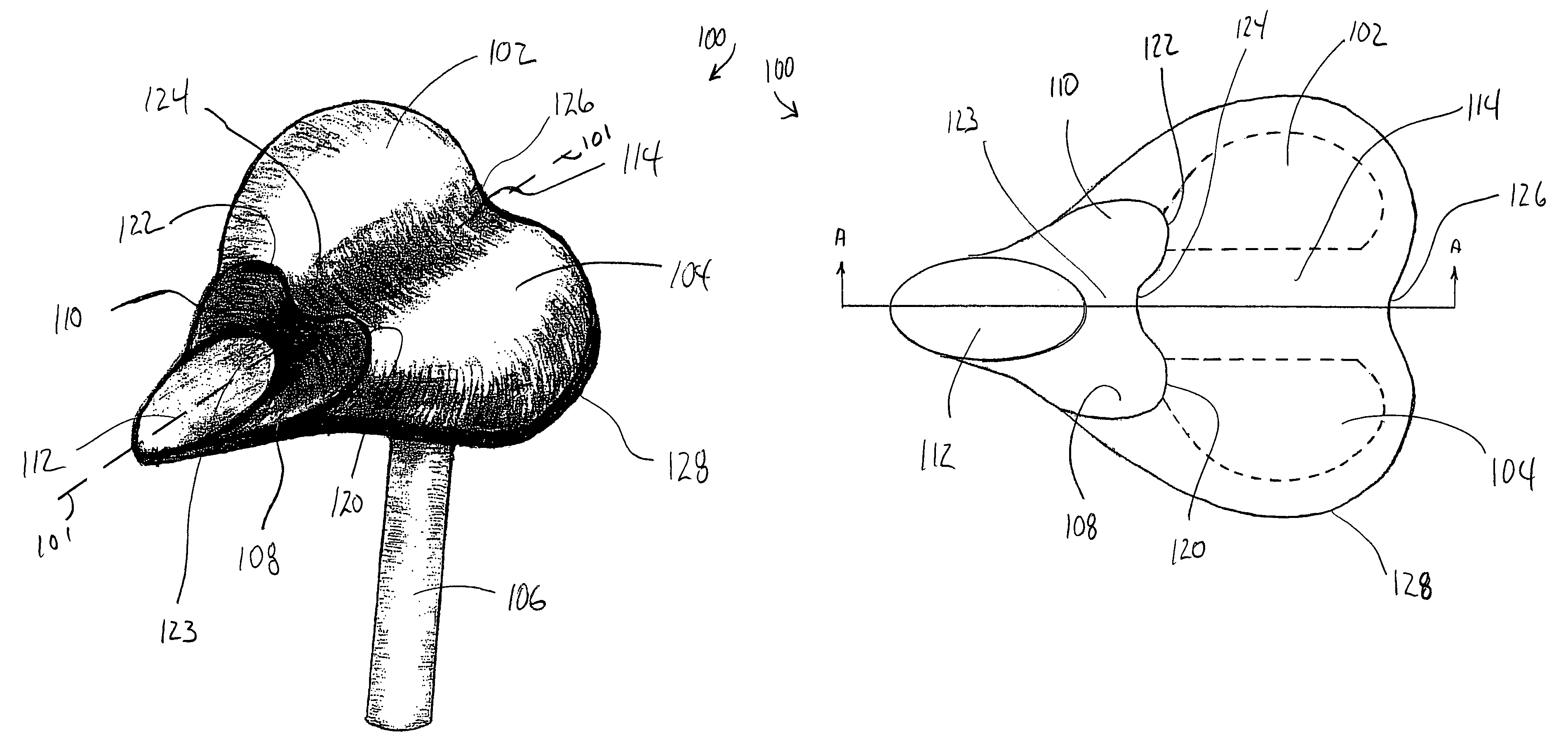

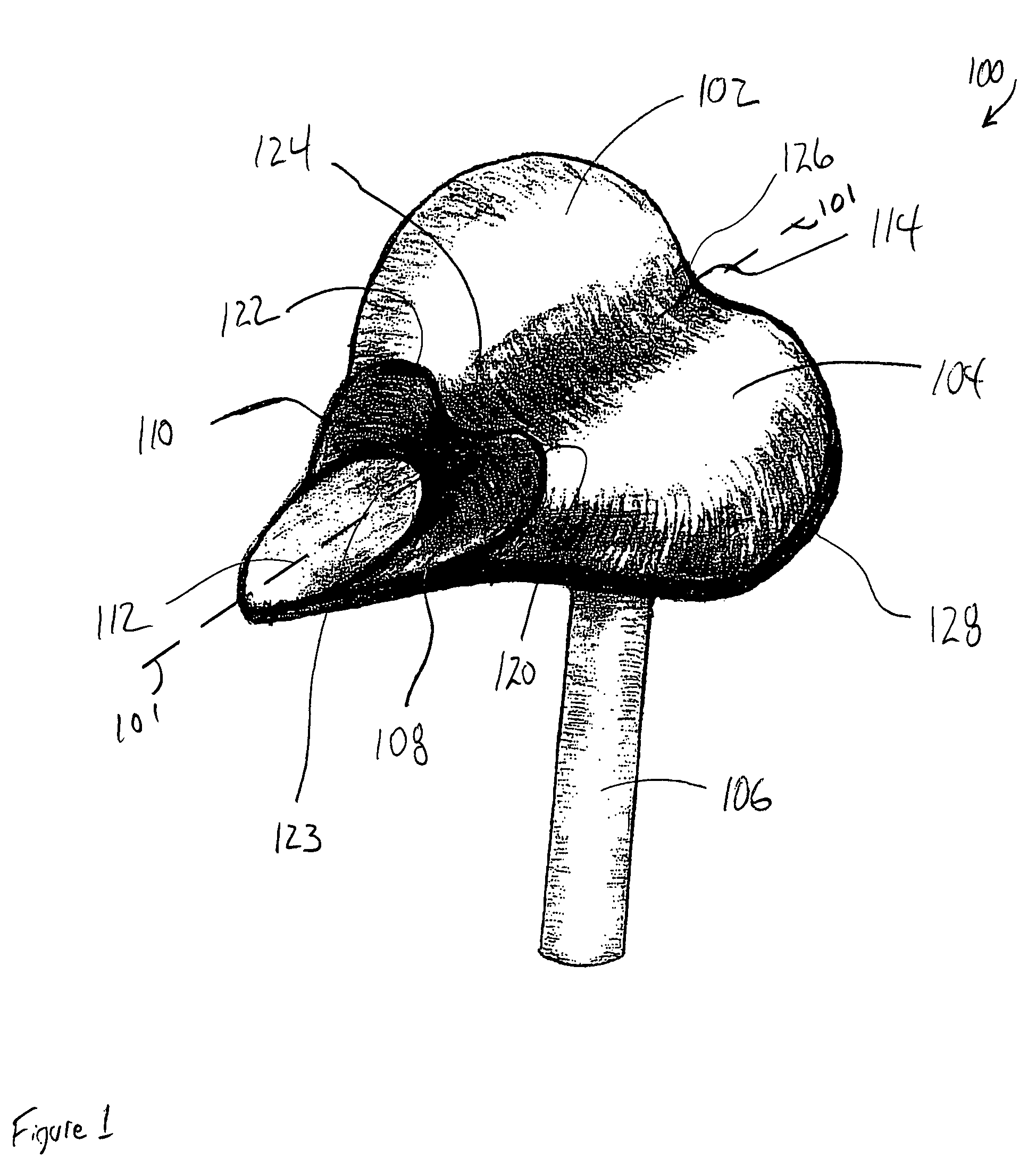

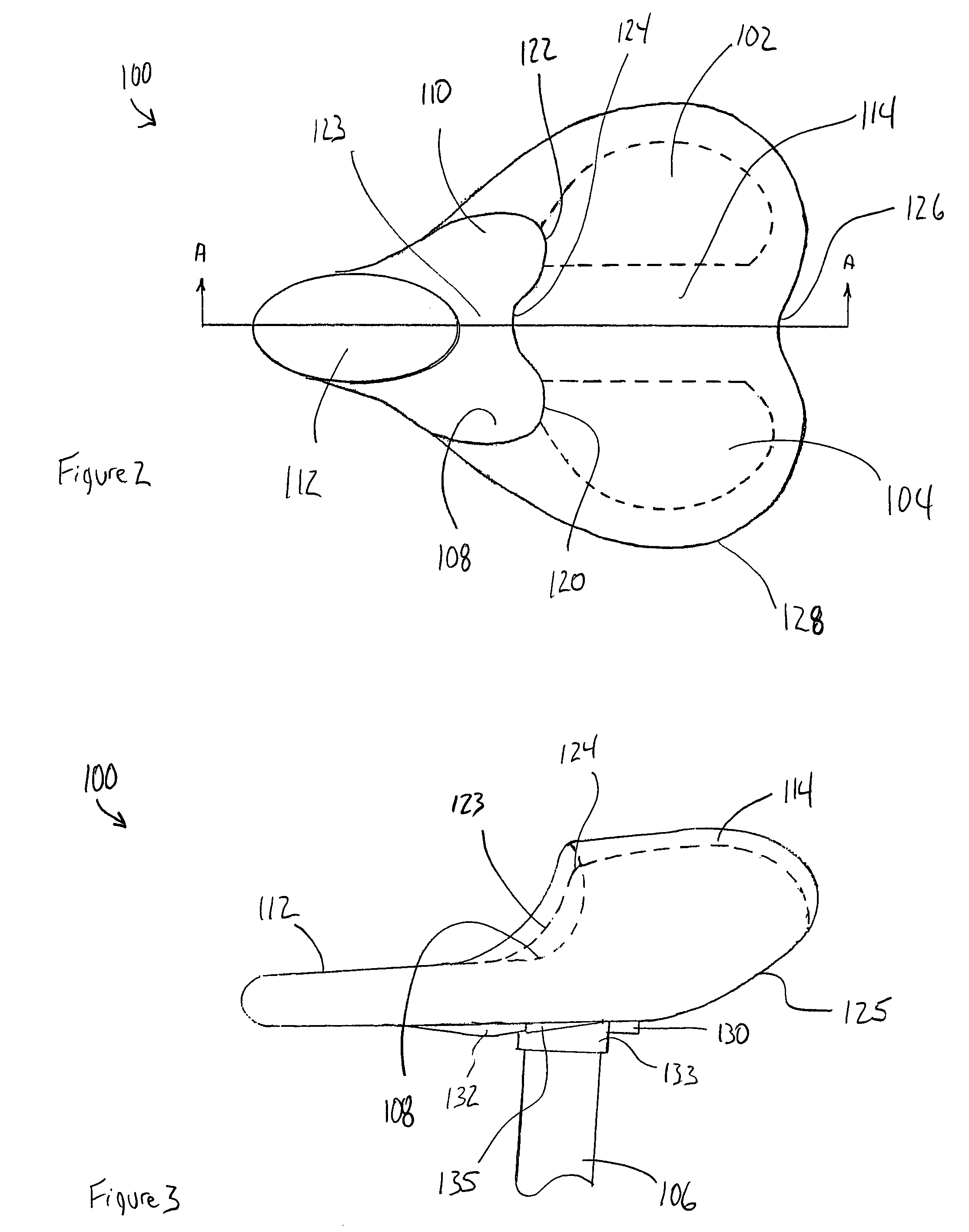

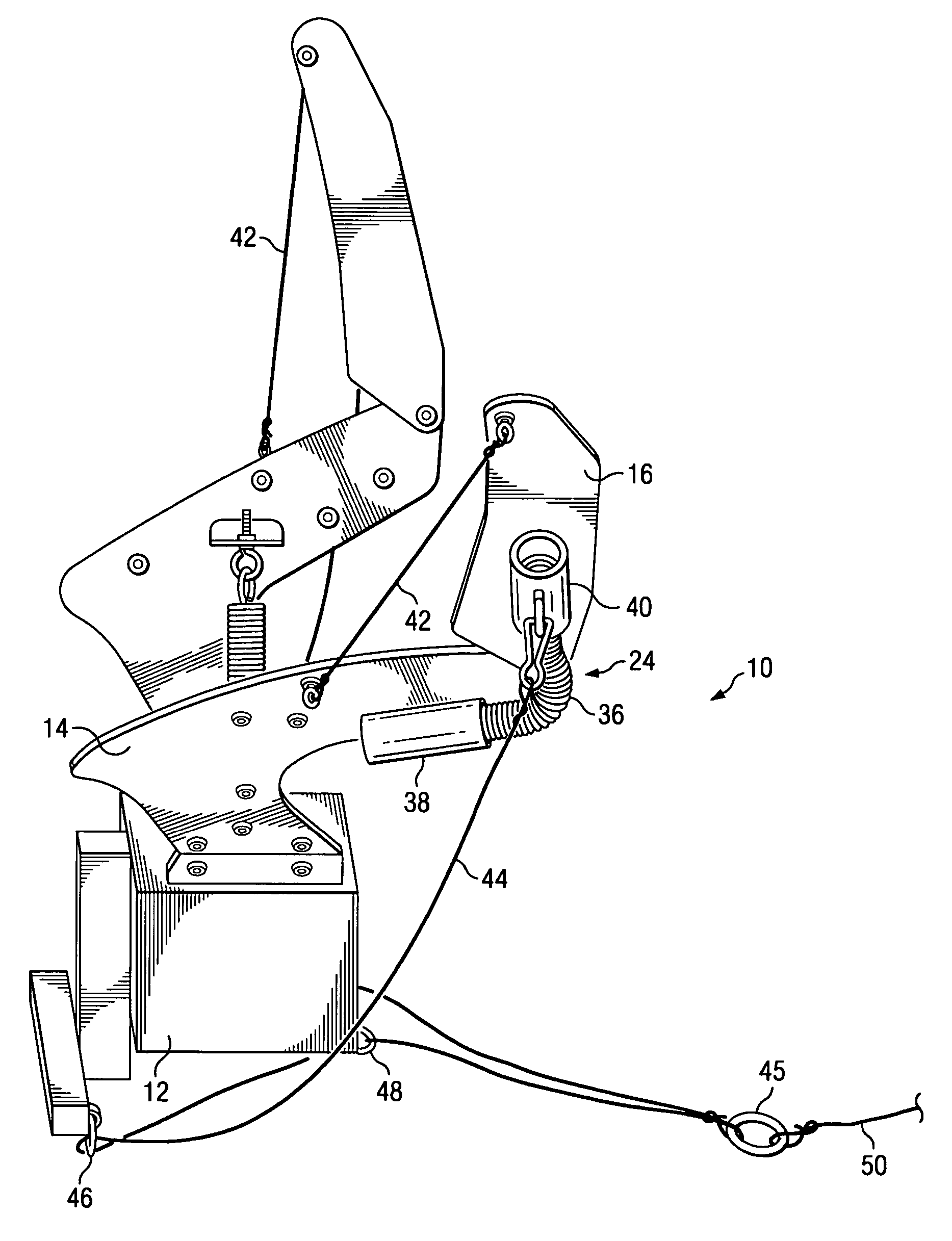

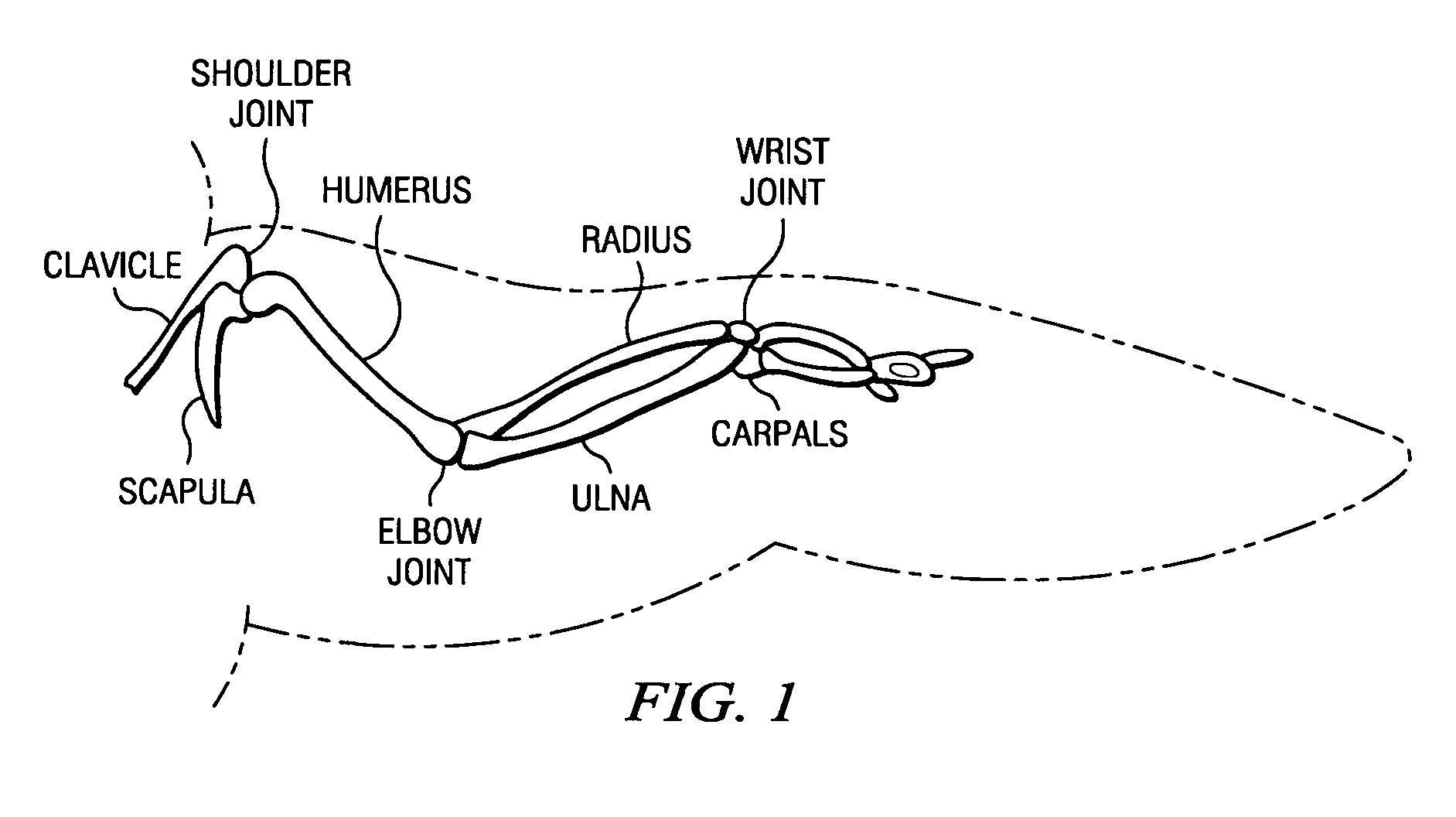

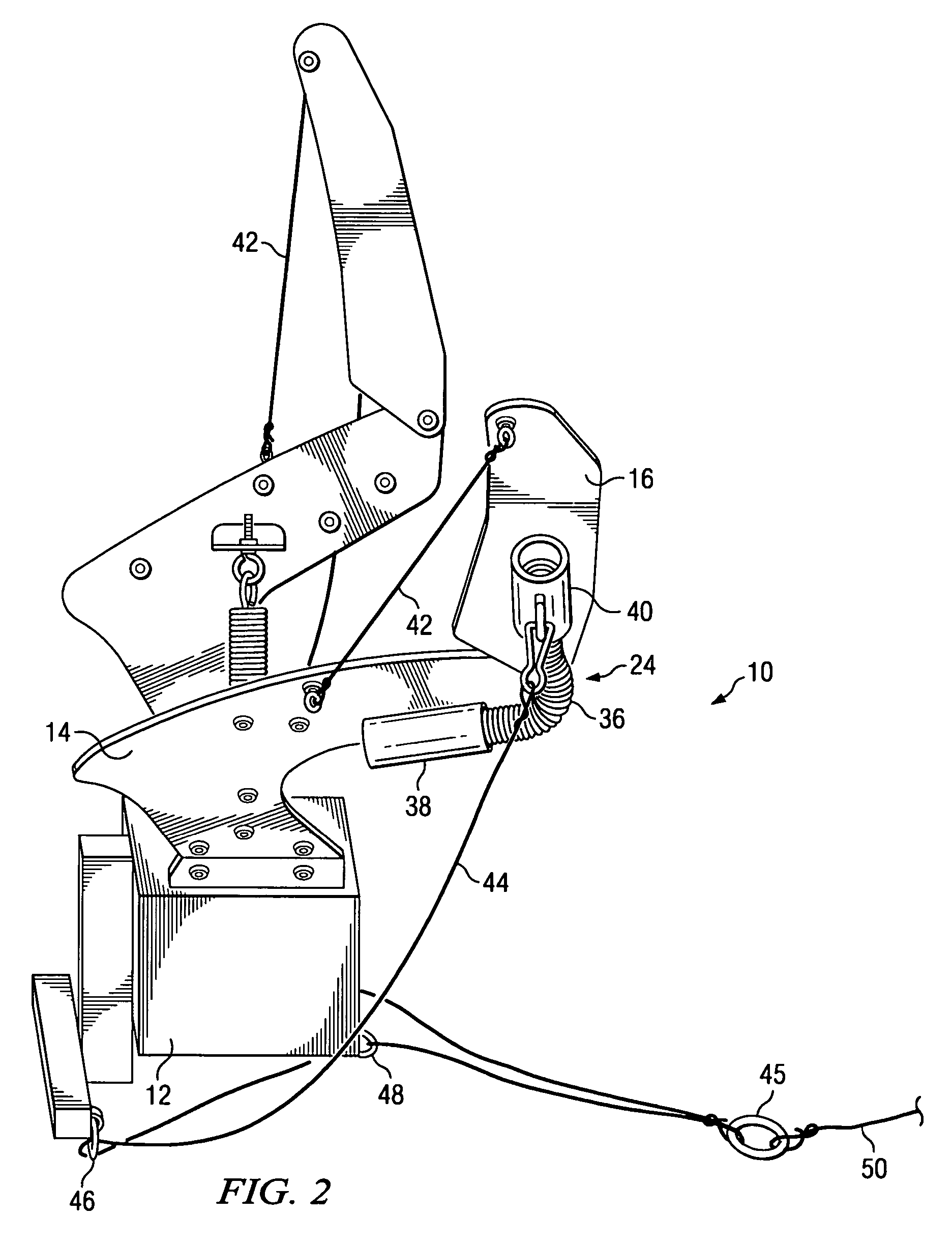

Anatomically supportive bicycle seat

Owner:CITY MARSHAL GEORGE AIRDAY +1

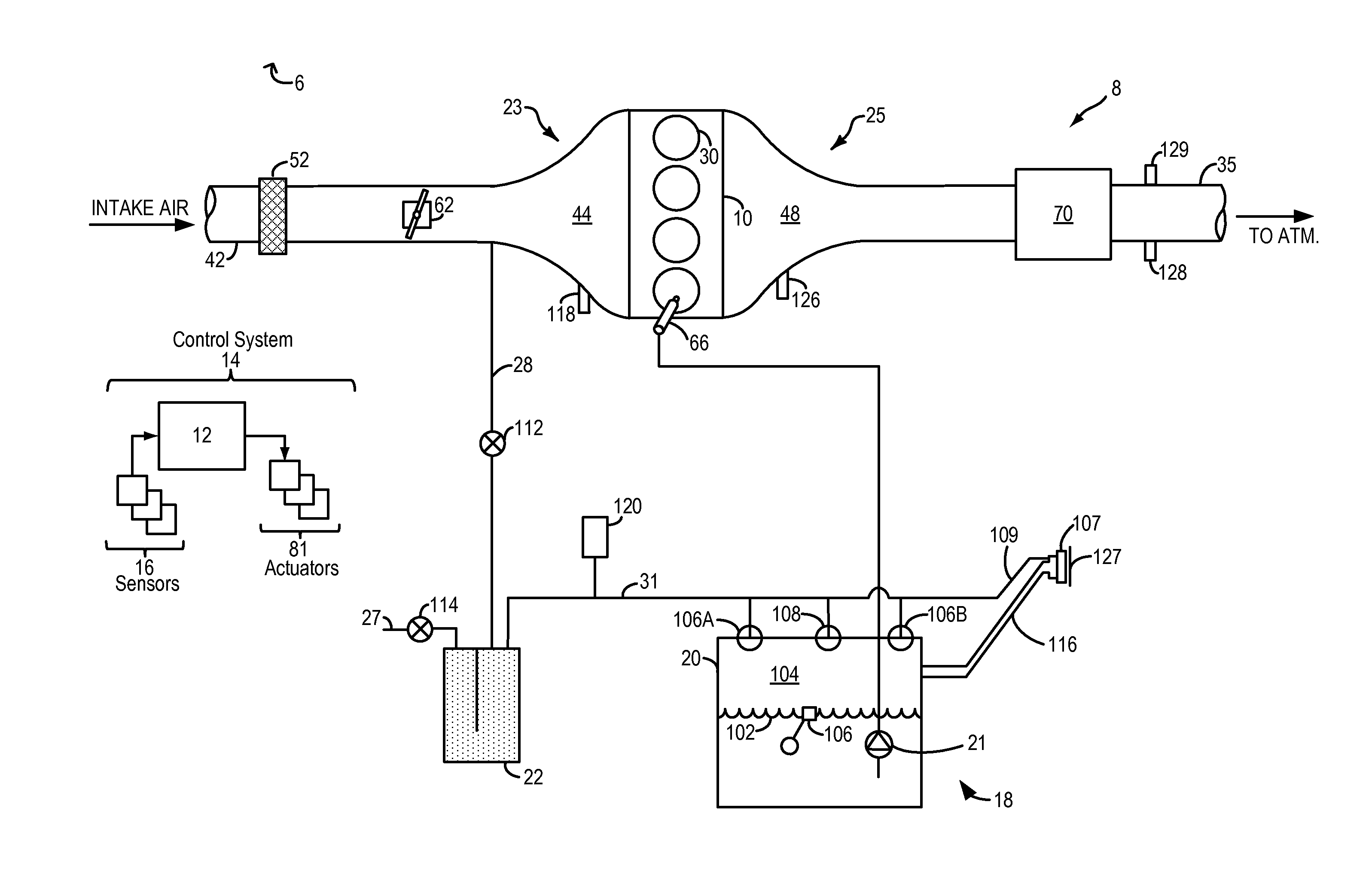

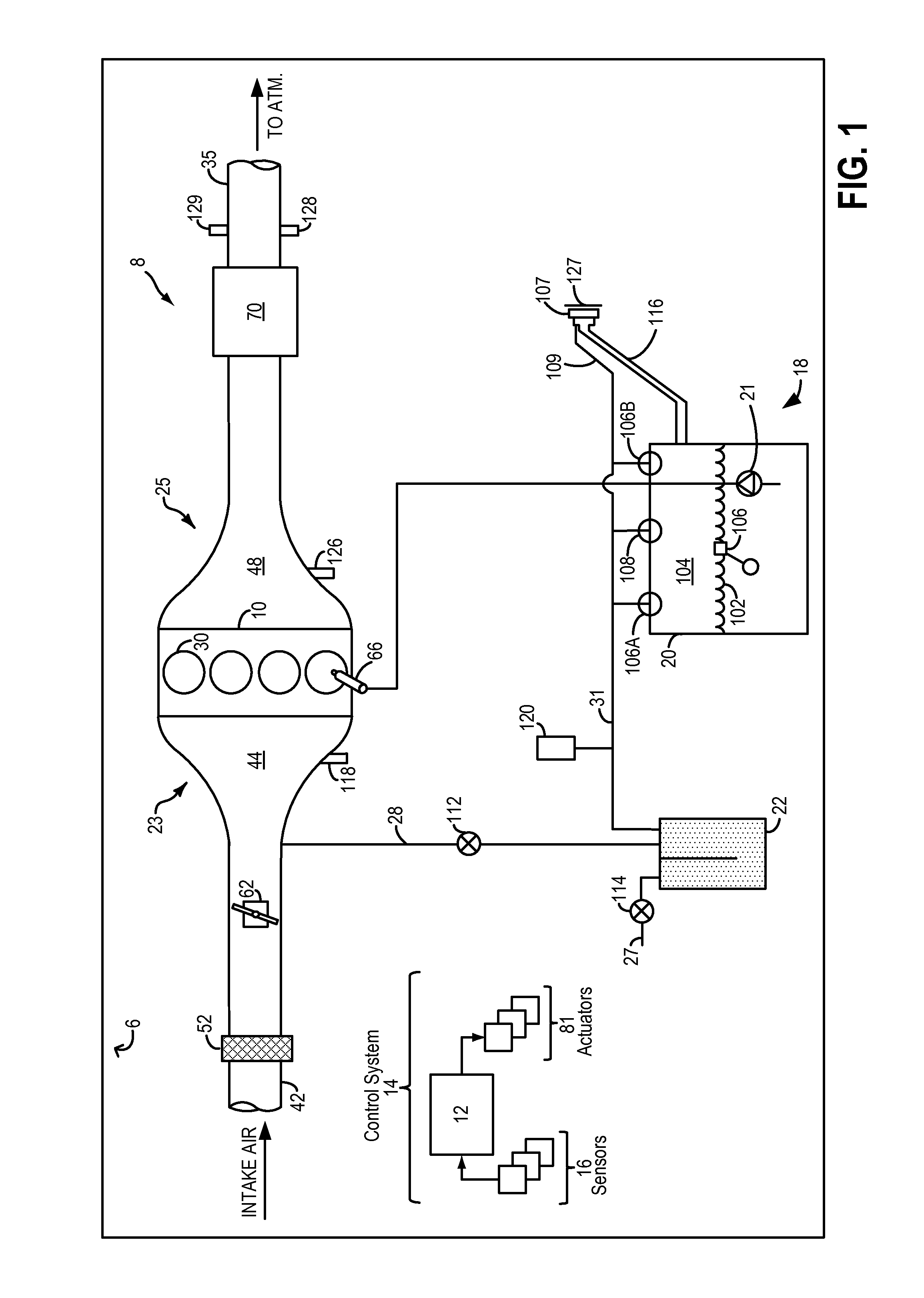

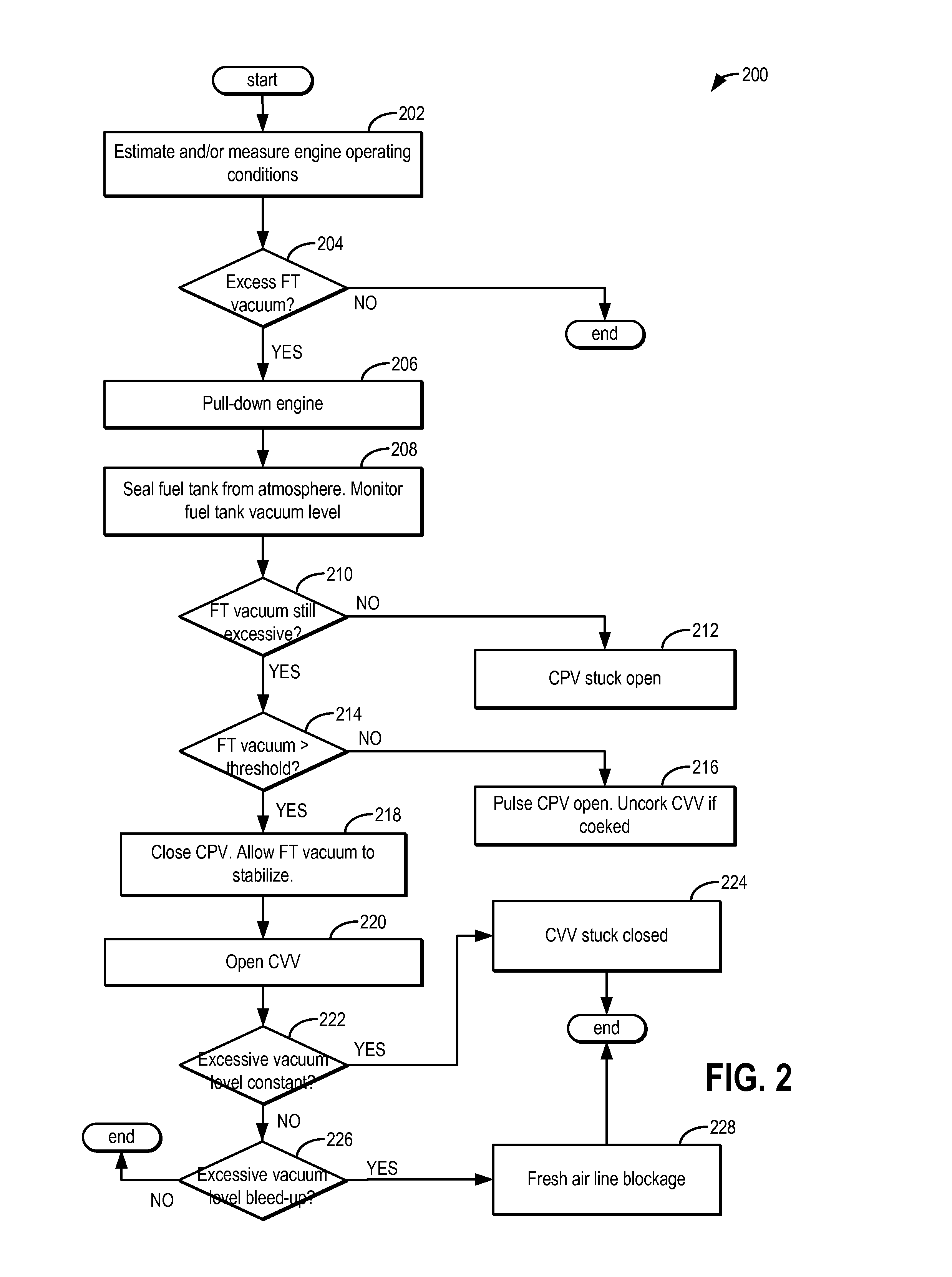

Fuel system diagnostics

ActiveUS20140130781A1Reduce releaseReduce noiseNon-fuel substance addition to fuelMachines/enginesExhaust valveFuel tank

Methods and system are provided for distinguishing fuel tank vacuum generation due to canister purge valve degradation from vacuum generation due to canister vent valve degradation. A fuel tank vacuum level is monitored after sealing the fuel tank from the atmosphere following an engine pull-down. If there is an ensuing change in fuel tank vacuum, canister purge valve degradation is determined, else, canister vent valve degradation is determined.

Owner:FORD GLOBAL TECH LLC

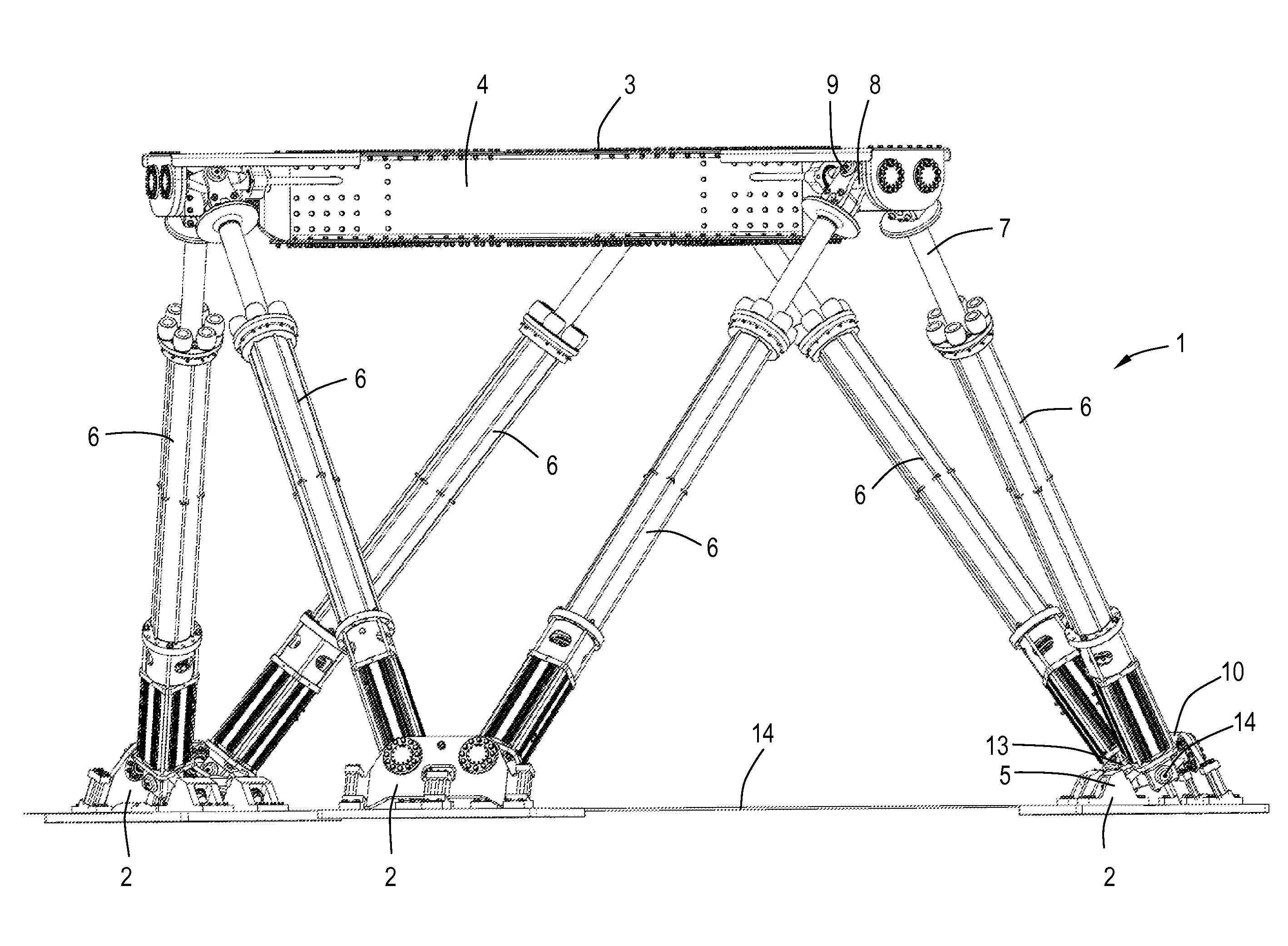

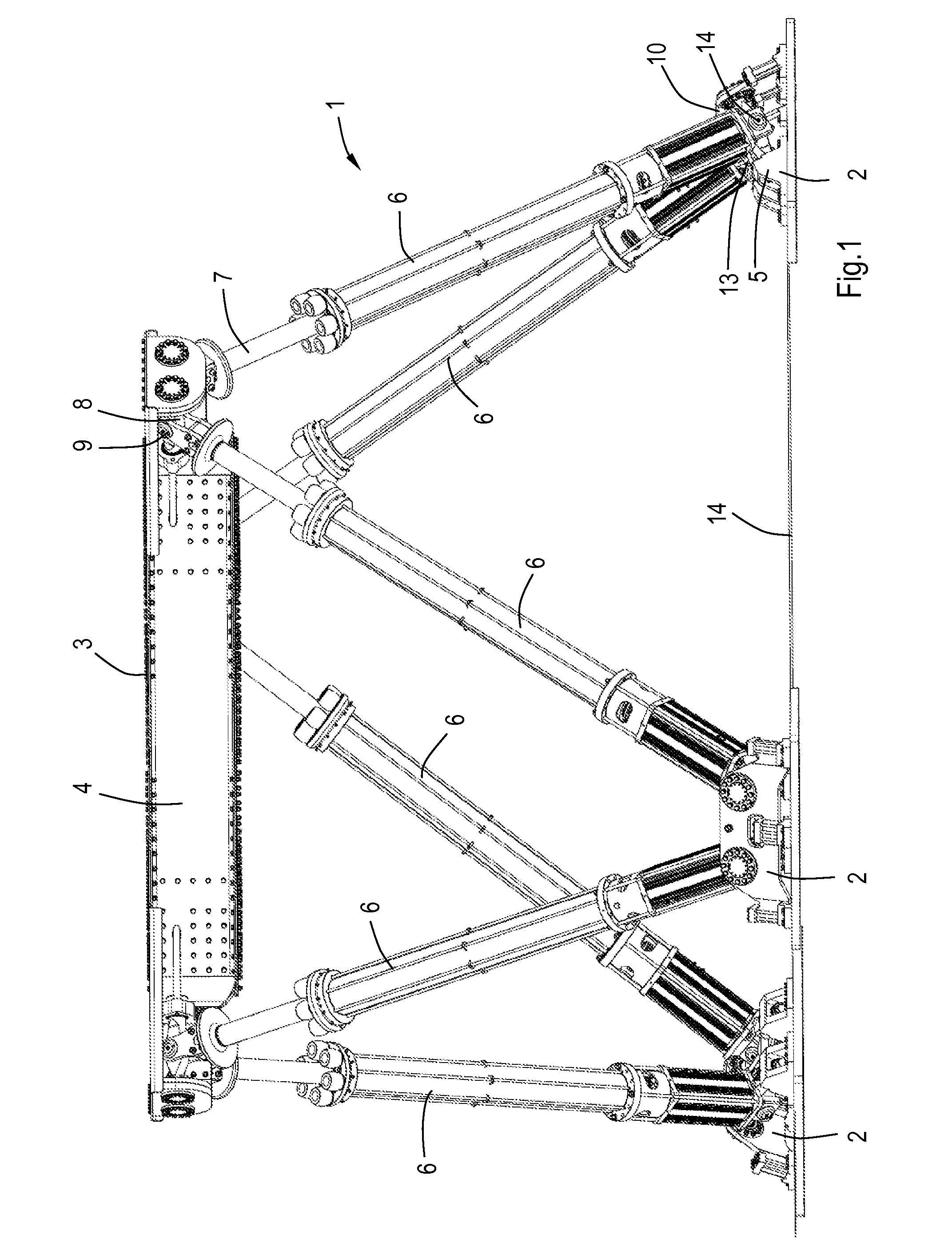

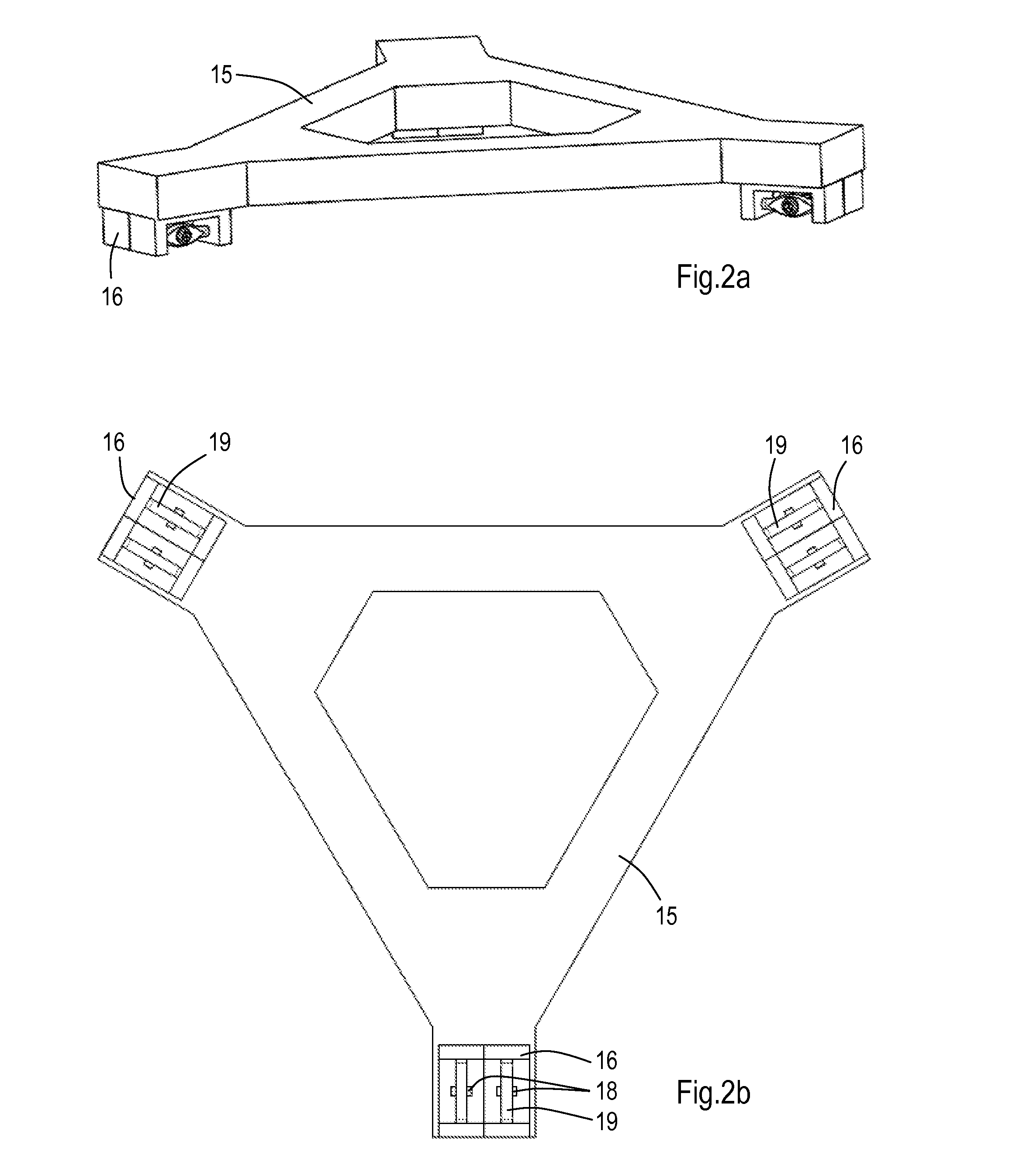

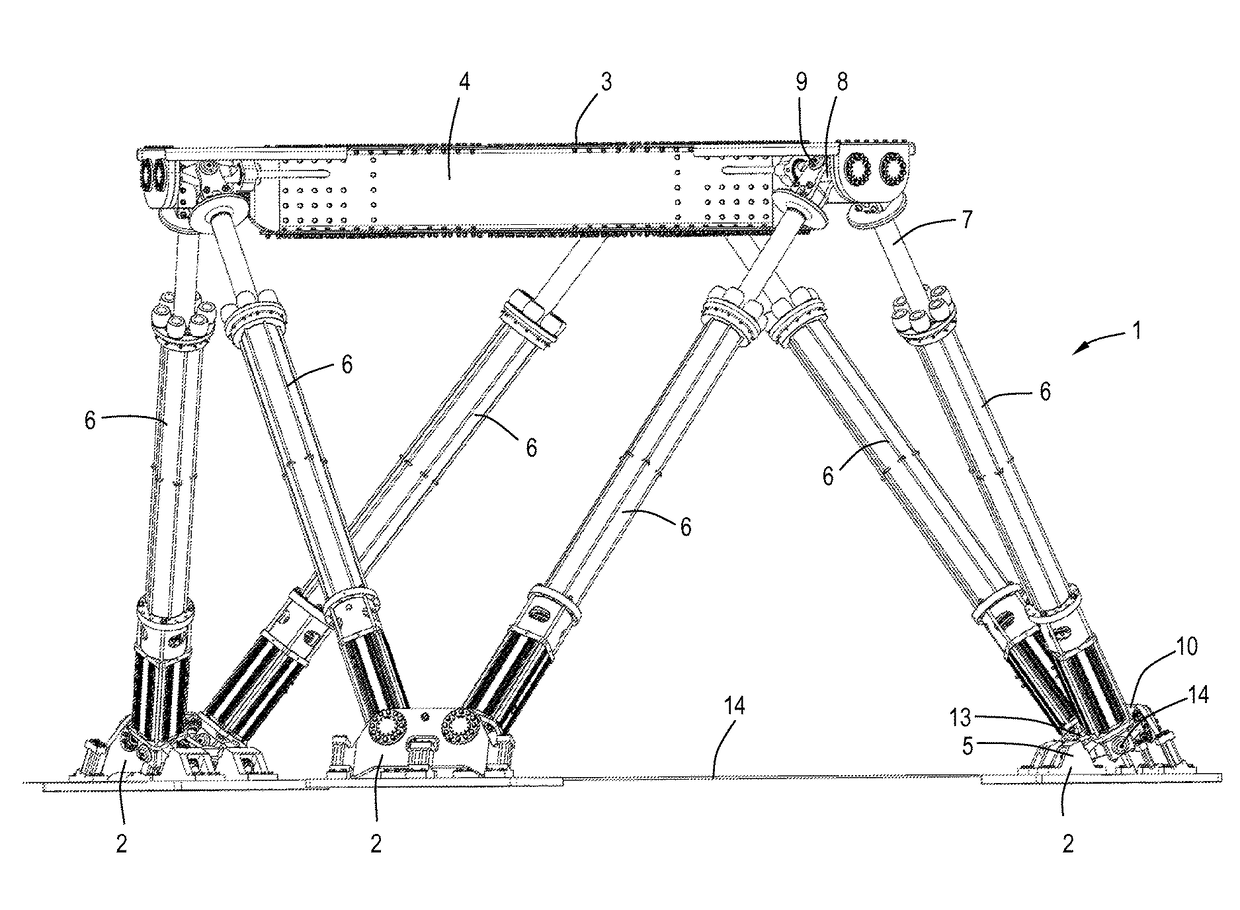

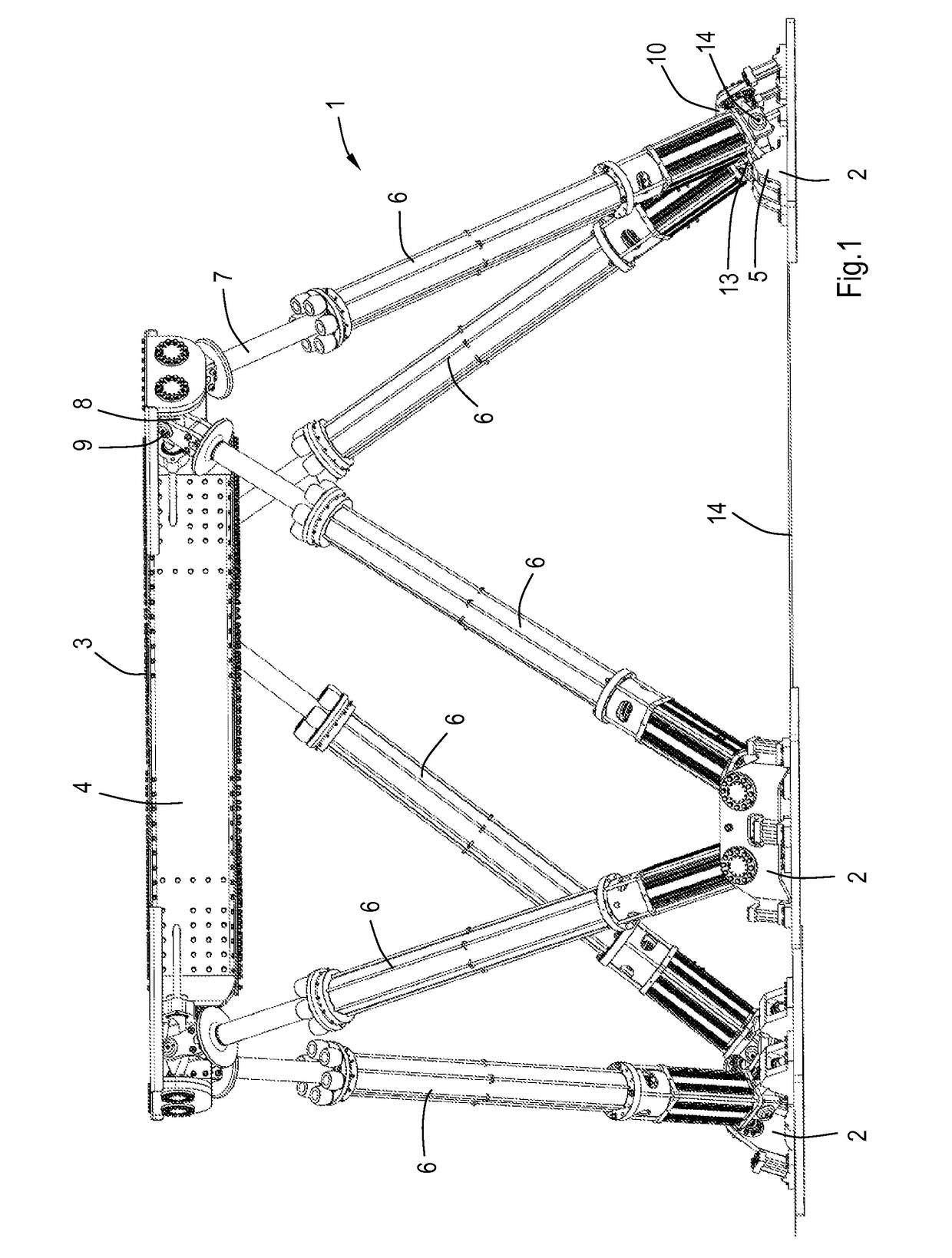

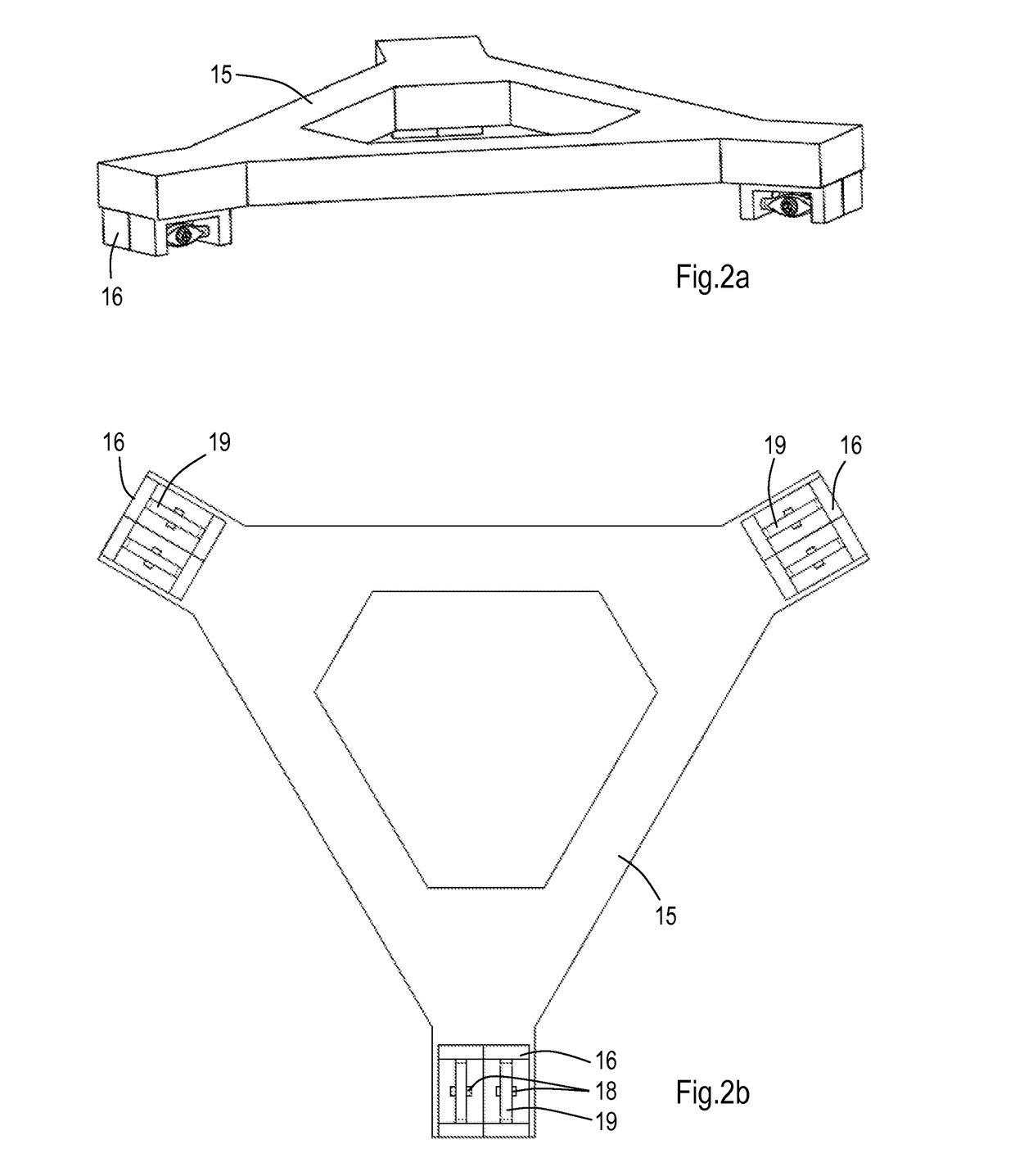

Six-degree-of-freedom motion simulator assembly

ActiveUS20160140862A1Increase forceLittle strengthCosmonautic condition simulationsSimulatorsEngineeringDegrees of freedom

The invention is directed to a 6 degree-of-freedom motion hexapod simulator assembly comprising of a fixed base, a displaceable simulator platform comprising of a load bearing structure, and 6 linear actuators having upper ends thereof interconnected with the load bearing structure by three pairs of two-degree of freedom joints and lower ends thereof interconnected with the fixed base by means of three pairs of two-degree of freedom joints. The two degree of freedom joint comprises of two rotatable pivot means which are oriented 90° with respect to each other. One pivot means runs through the other pivot means. At the connection with the load bearing structure the centre of one joint of a pair of joints is separated by part of the load bearing structure from the centre of the other joint of the pair of joints.

Owner:E2M TECH

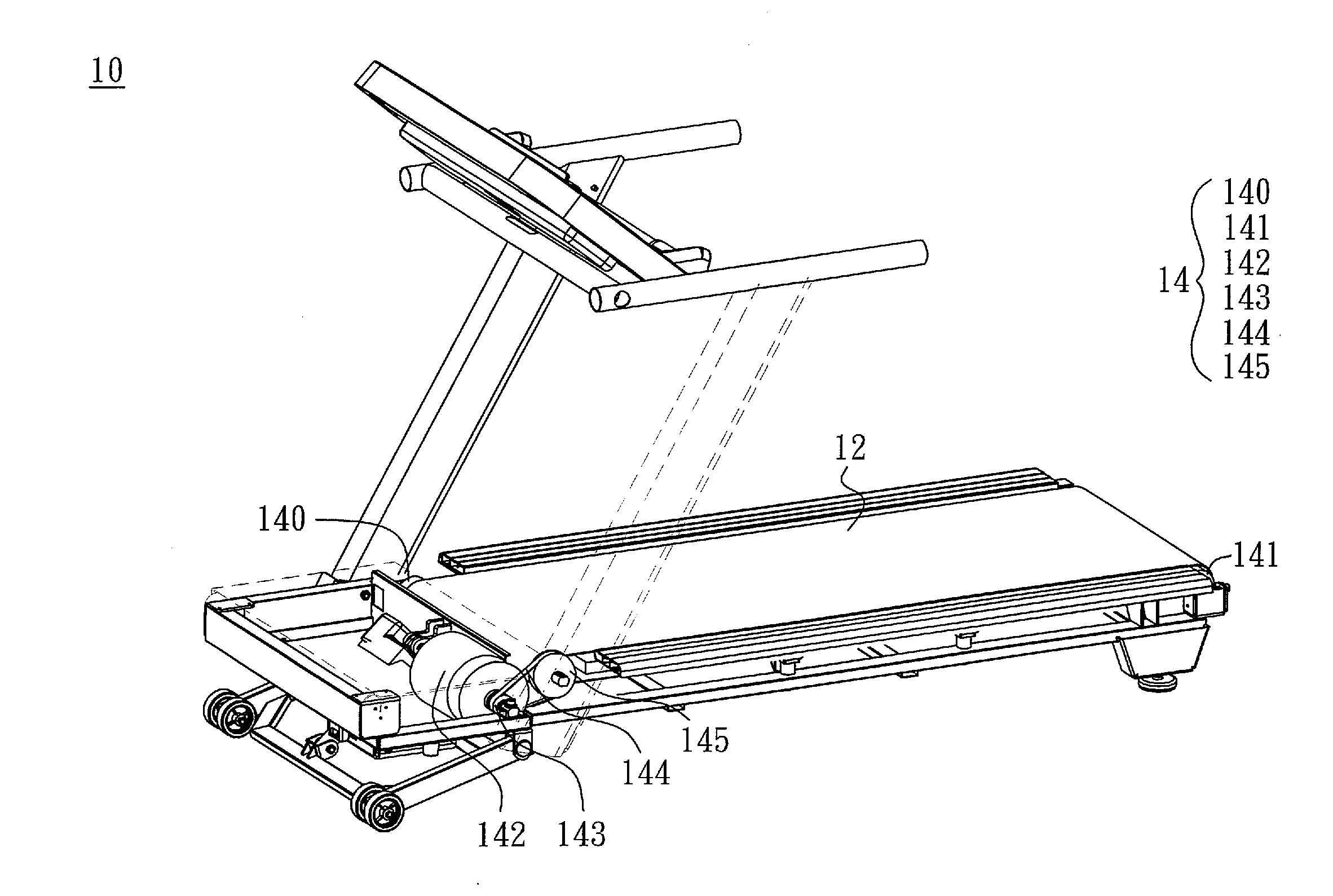

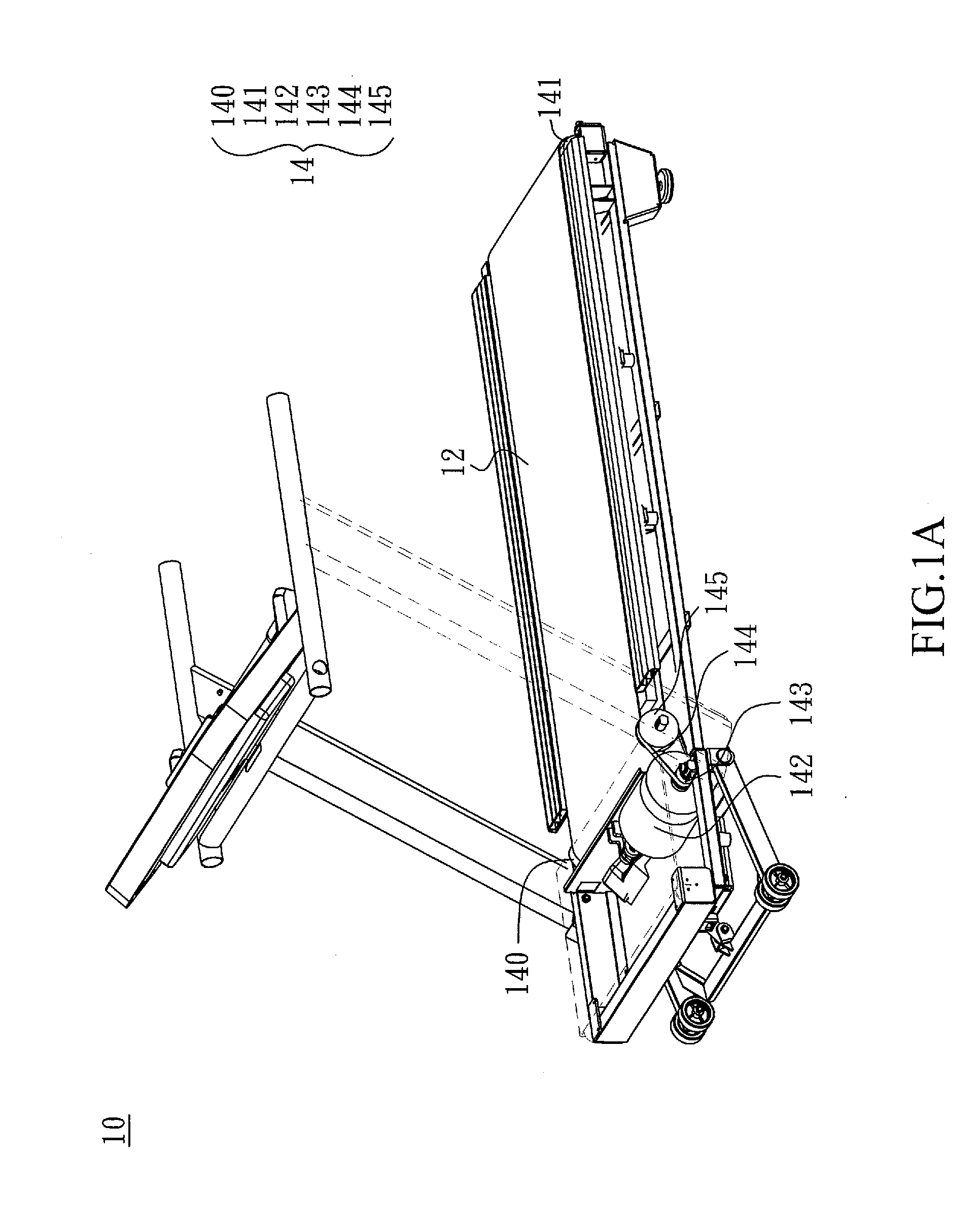

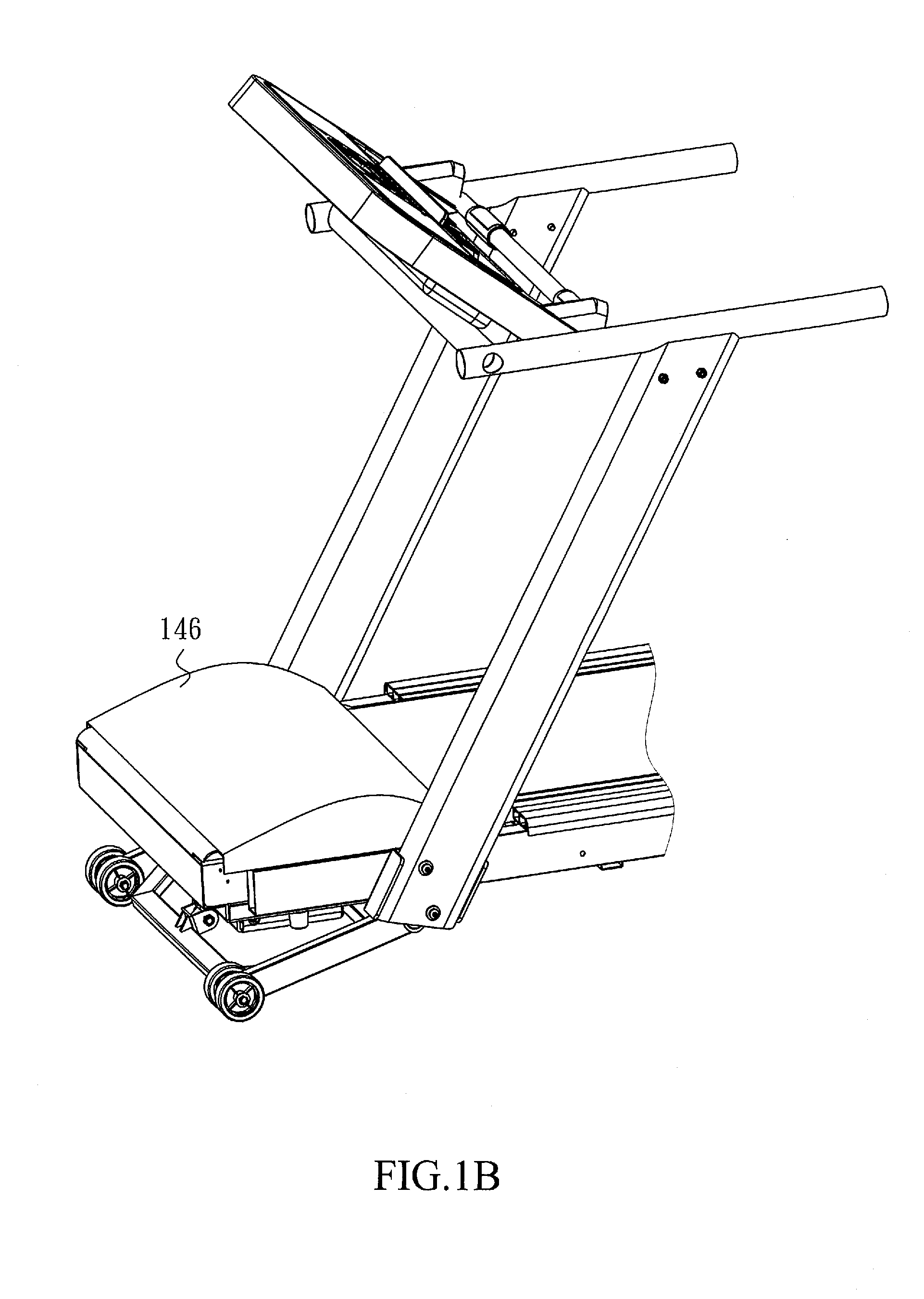

Flattened treadmill

InactiveUS20160016035A1Improve securityReduce harmMovement coordination devicesCardiovascular exercising devicesElectric machineryTreadmill running

Owner:DYACO INT INC

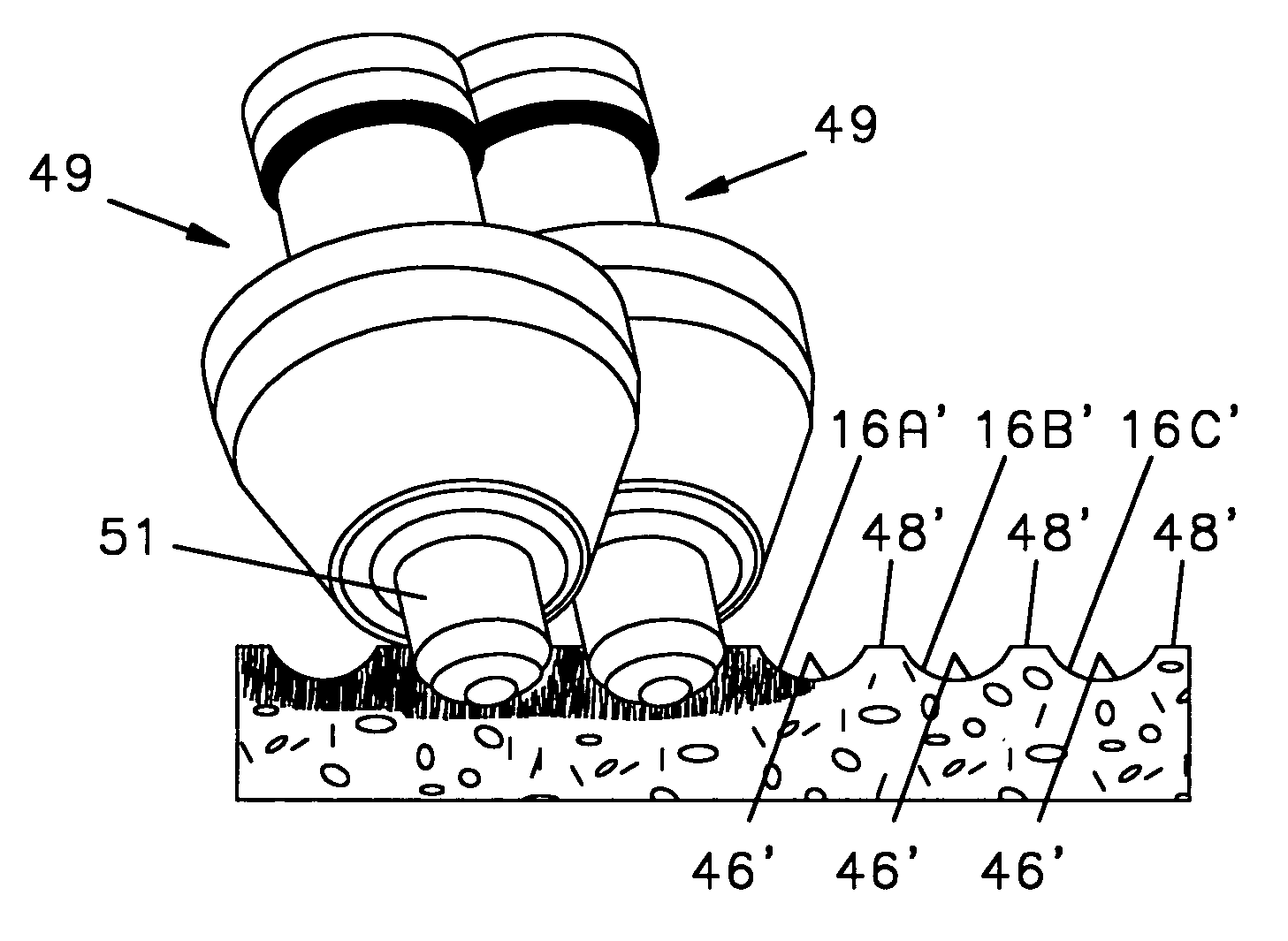

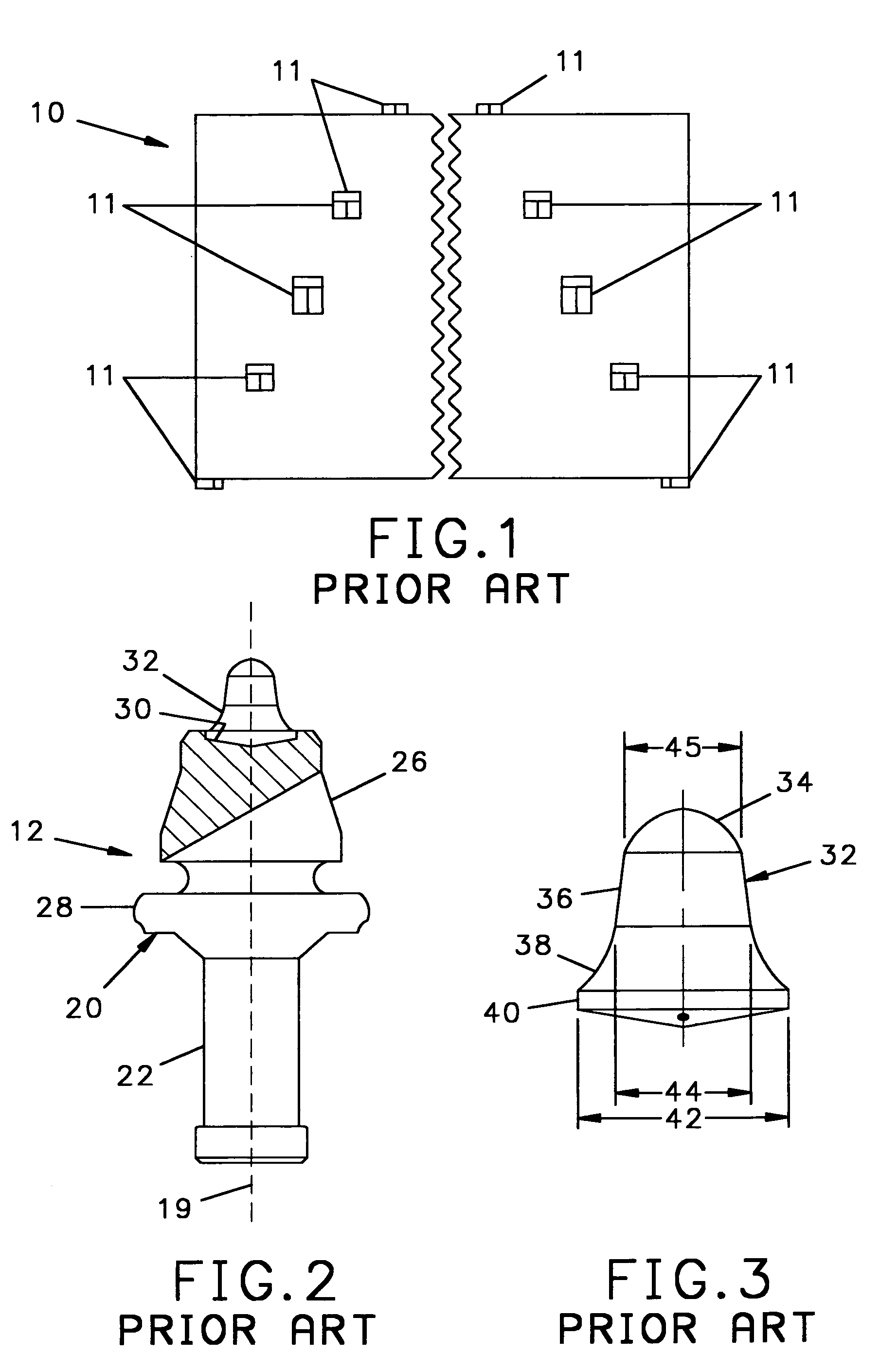

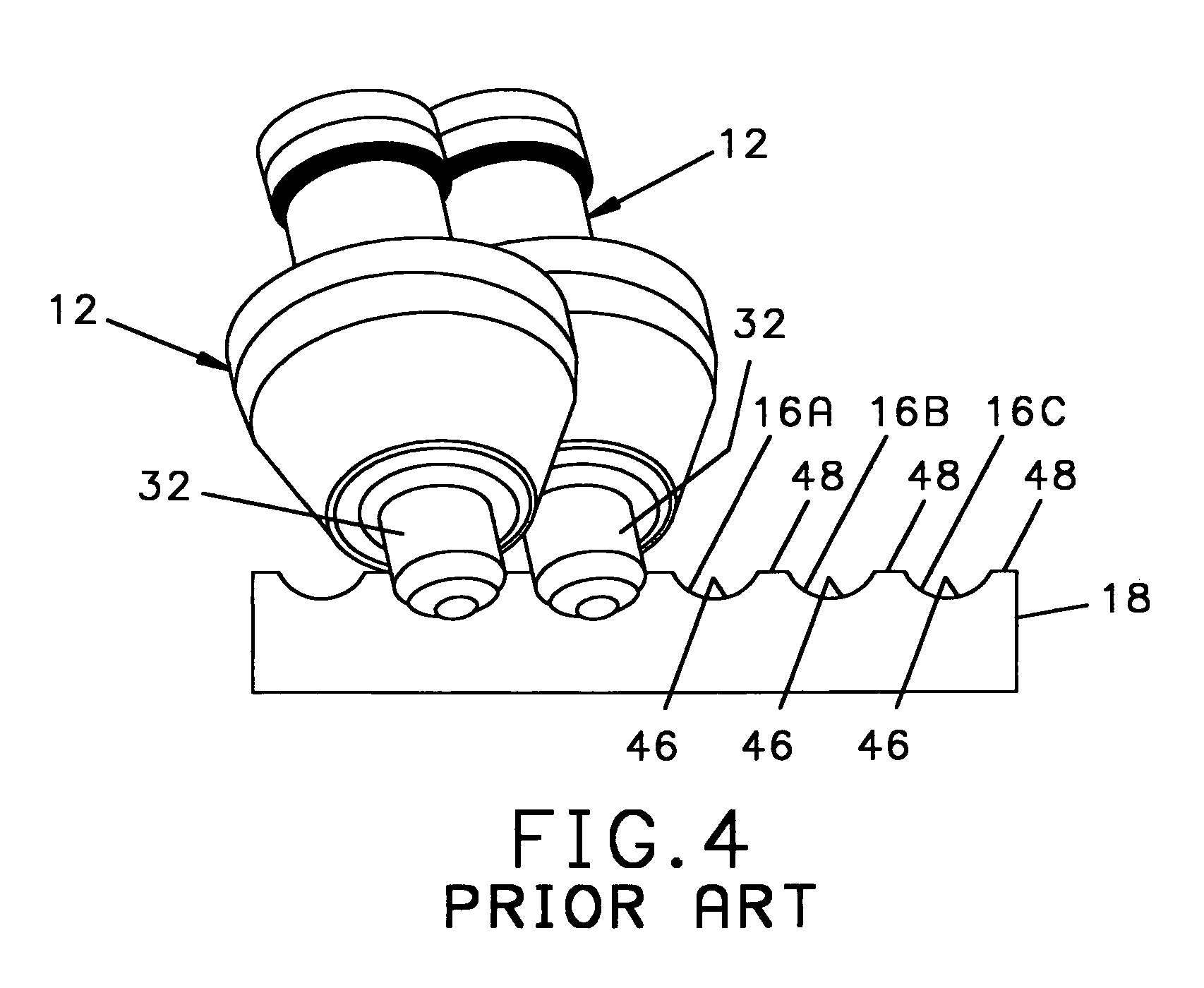

Hardened rotary cutting tip

ActiveUS6986552B1Smooth rotationMaximum service lifeDisloding machinesSlitting machinesKnife bladesErosion

An insert for a cutting tool has a conical cutting tip, and axially behind the cutting tip is a mid-section. Behind the mid-section is a cylindrical base. Where the insert is for use on a tool of a milling machine, the base has a diameter of at least 0.800 inch so as to be considerably larger than the standard base of inserts currently in use on such machines. The enlarged base protects the tool body to which the insert is attached from washaway. The invention is useable in other industries employing rotary cutting tools. In other industries, the insert is made with an enlarged diameter base so as to protect the tool body behind the insert from erosion or washaway. Indentations in the outer circumference of the base improve the rotation of the tool and provide channels through which loosened particles of hard material are directed, thereby further reducing erosion of the tool body.

Owner:THE SOLLAMI COMPANY

Wing structure for a waterfowl decoy

Owner:HALEY PATRICK

Manufacturing process for an adherent silicone healing tape/pad/dressing of specific shapes

InactiveUS20190314544A1Factor is lowPractical and safe and accurateAdhesive dressingsAbsorbent padsChemical reactionMedicine

A new MANUFACTURING PROCESS FOR AN ADHERENT SILICONE HEALING TAPE / PAD / DRESSING OF SPECIFIC SHAPES, for application in the medical area aiming to provide greater results in the healing of keloid scars as a fibroproliferative disorder, since the following specific properties make silicone useful for dressings: safe, low thermal conductivity, low chemical reactivity, low toxicity and rare adverse reactions, as the silicone cannot be absorbed into the body, repels the water and creates a watertight seal, it does not support microbial growth, has high gas permeability, and is adherent to dry skin.

Owner:MARIA CRISTINA DE PAULA MESQUITA +1

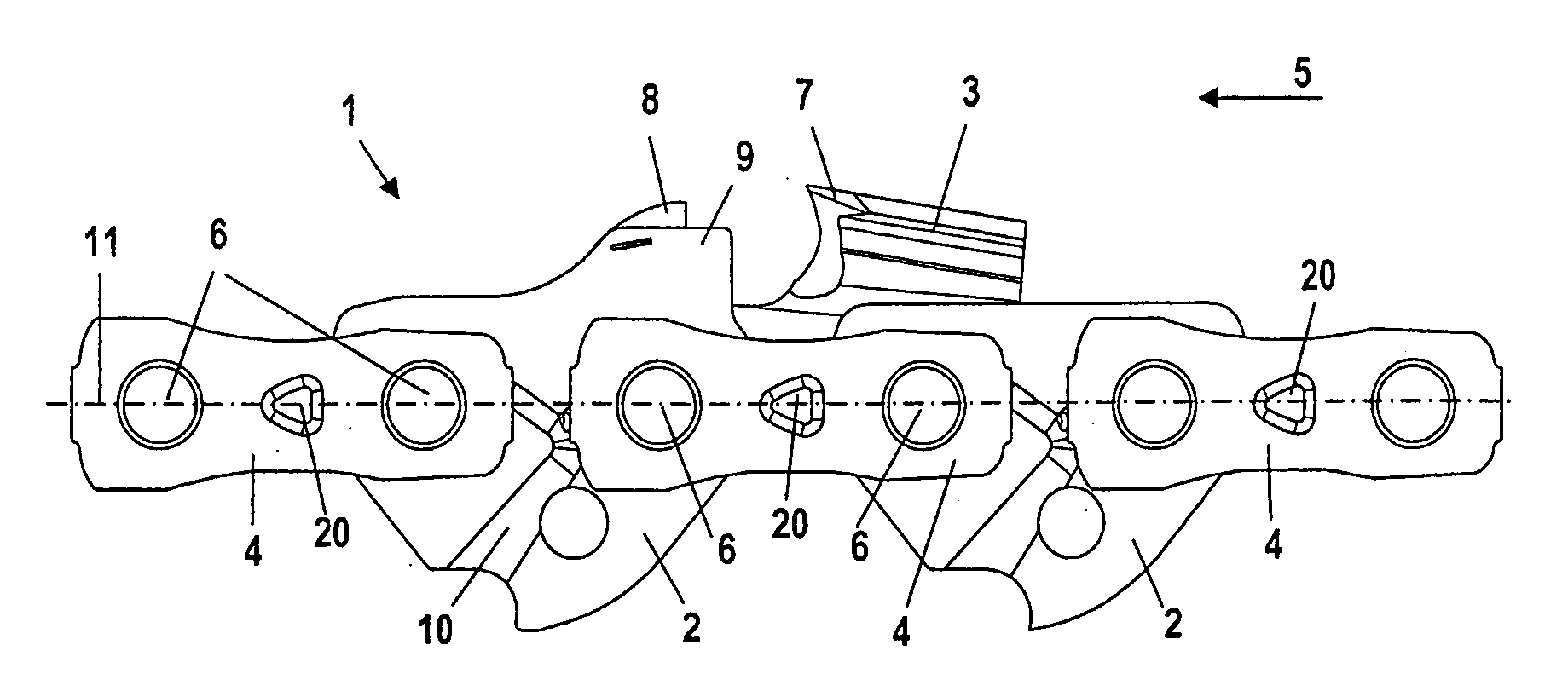

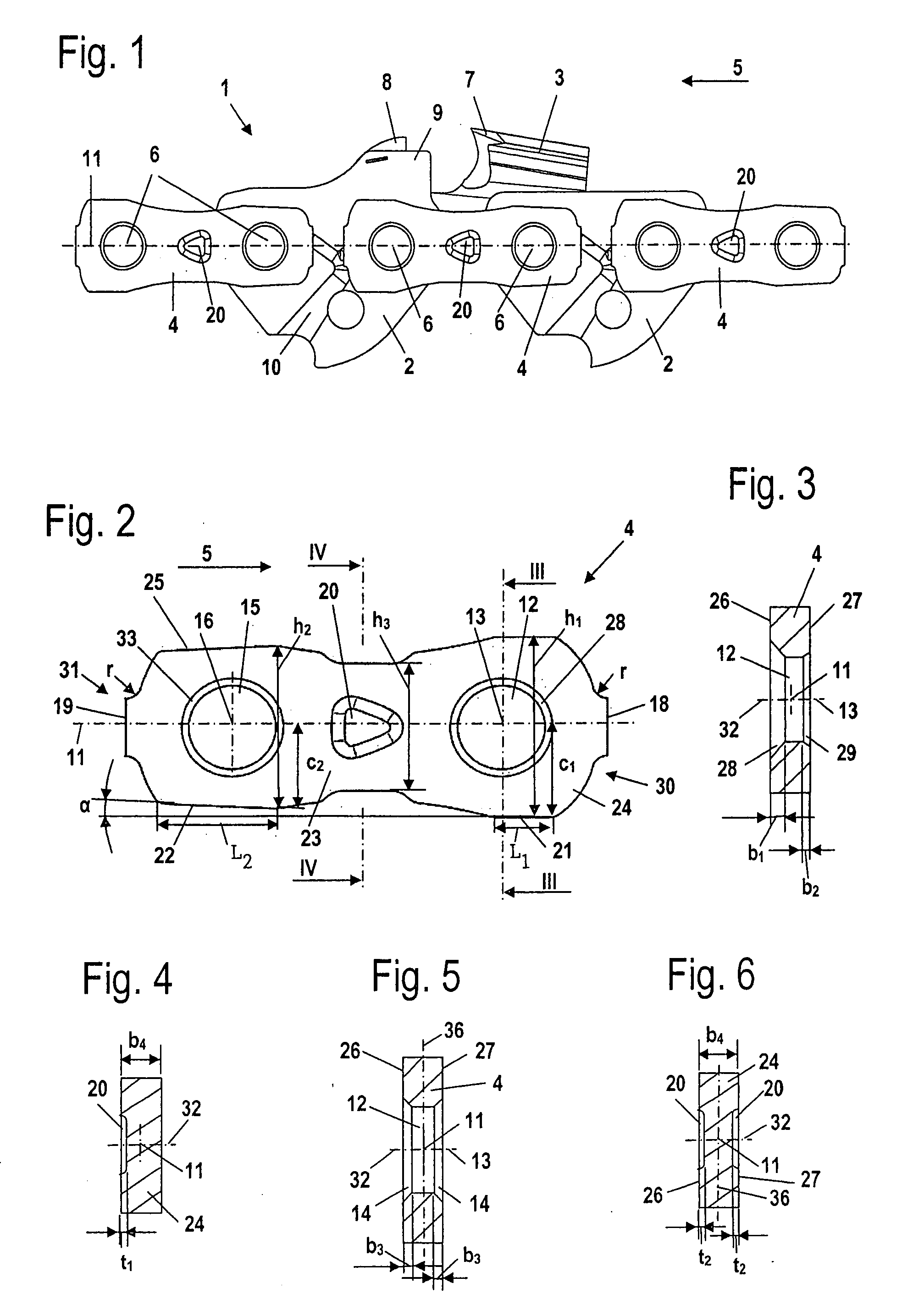

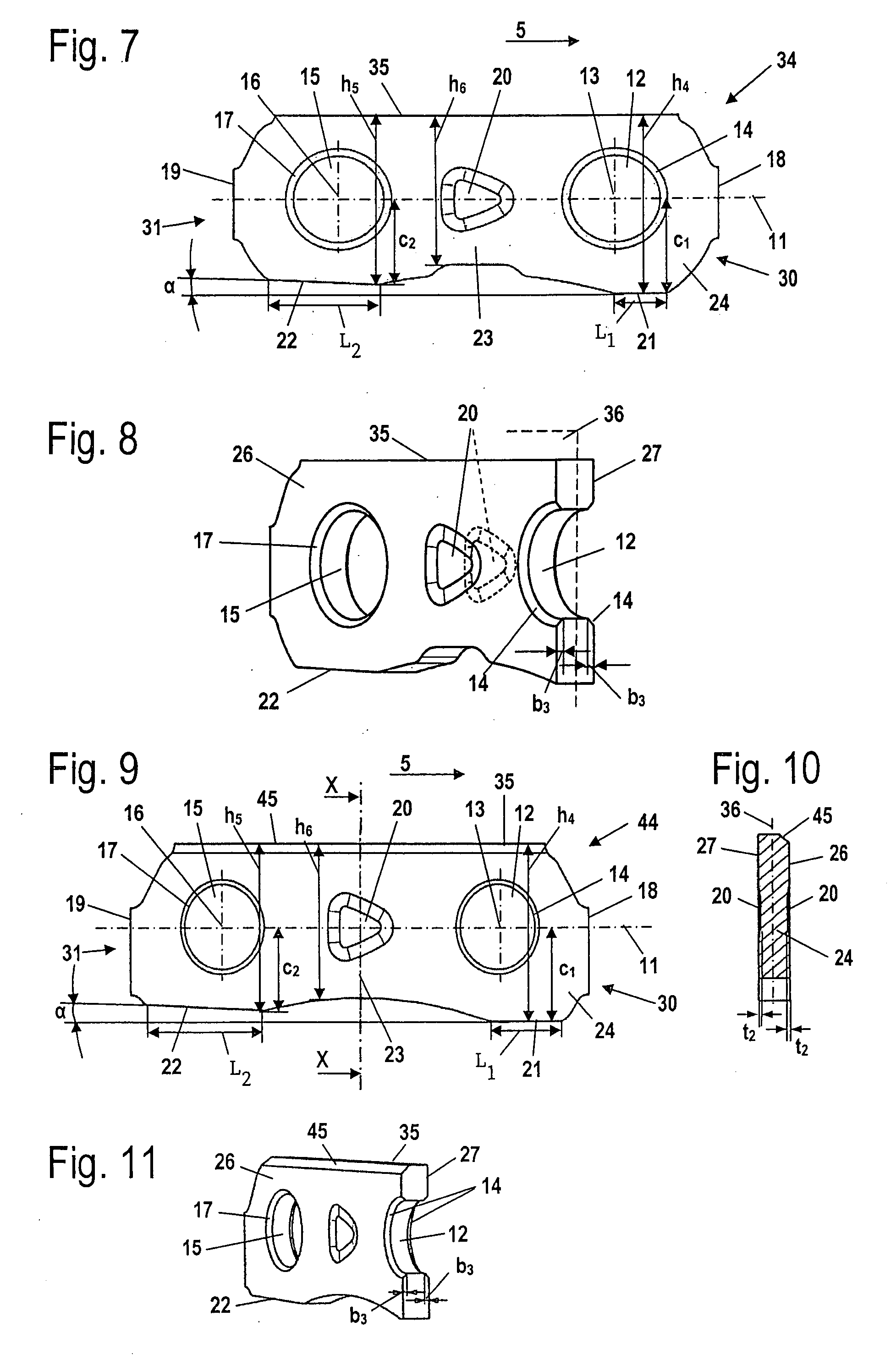

Connecting link for a saw chain

InactiveUS20080034938A1Easy to assembleEasy to processSaw bladesMetal working apparatusChain sawRivet

A connecting link (4, 34) for a saw chain (1) of a motor-driven chain saw has an areal base body (24) which has two rivet openings (12, 15). The connecting link (4, 34, 44) has a longitudinal center axis (11) which intersects the axes (13, 16) of rivet openings (12, 15) and runs in the base body (24). The functional regions of the connecting links (4, 34, 44) are mirror symmetrical to planes (32, 36), which contain the longitudinal center axis (11), and are unsymmetrical to each plane perpendicular to the longitudinal center axis (11). In this way, the connecting link (4, 34, 44) can be arranged on both longitudinal sides of the saw chain (1).

Owner:ANDREAS STIHL AG & CO KG

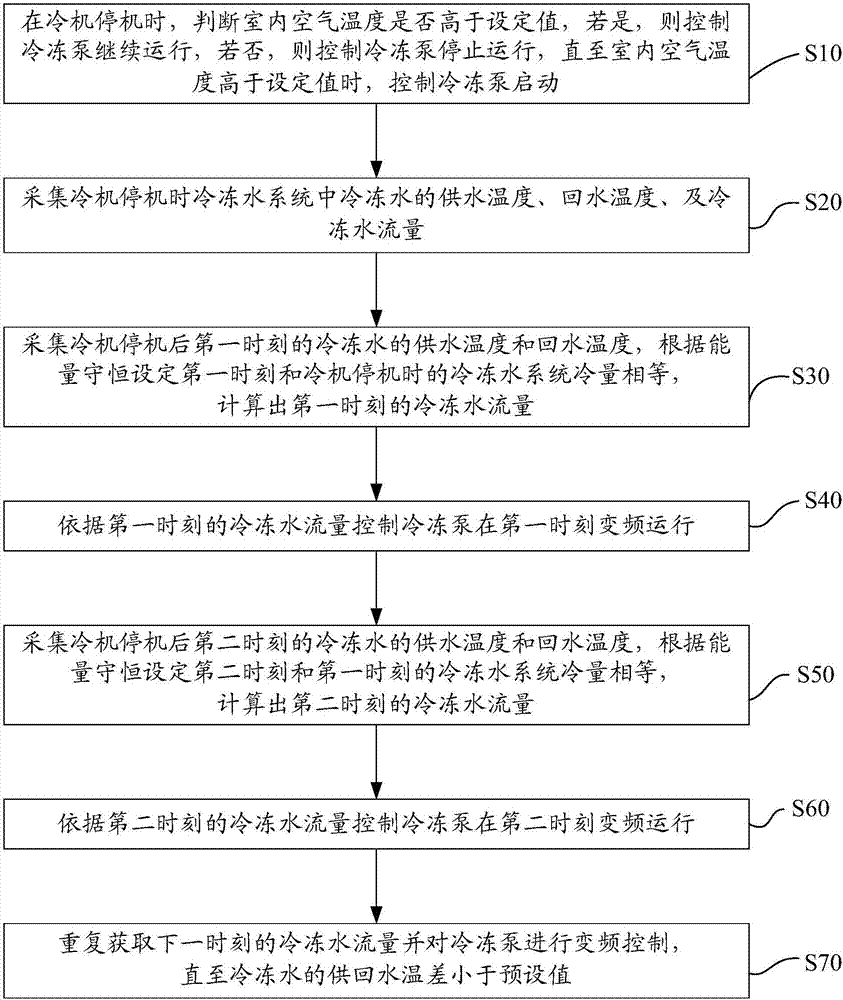

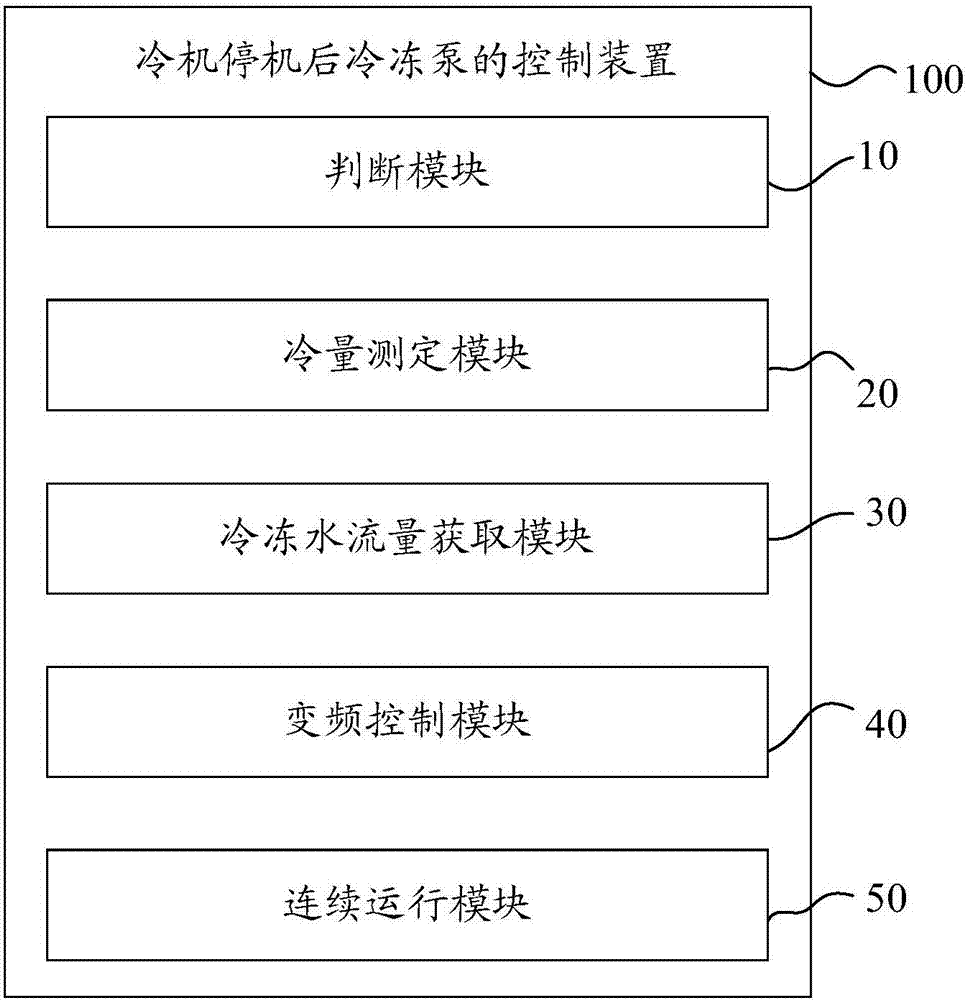

Control method and control device of freezing pump after refrigerator closing down and central air conditioner system

ActiveCN106989477AReduce elevationReduce energy consumptionMechanical apparatusSpace heating and ventilation safety systemsWater flowEngineering

The invention provides a control method and control device of a freezing pump after refrigerator closing down and a central air conditioner system. During refrigerator closing down, the water supply temperature, the water returning temperature and the freezing water flow of freezing water in a freezing water system are collected so as to obtain the remaining cold amount of a freezing water system, the water supply temperature and the water returning temperature of the freezing water are collected at the first moment after closing down, the energy conservation is used for enabling the cold amount at the front moment and the cold amount at the rear moment to be equal, the freezing water flow at the first moment is calculated, according to the freezing water flow, the freezing pump at the first moment is controlled to run in a frequency-converting manner, the freezing water flow at the second moment is obtained, the freezing pump is controlled to run in a frequency-converting manner, the freezing water flow of the next moment is repeatedly obtained, and the frequency converting running of the freezing pump is controlled until the water supply and returning temperature difference of freezing water is smaller than 1 DEG C. According to the method, through control over frequency-converting running of the freezing pump, the remaining cold amount in the freezing water system is continuously subject to heat exchange with the indoor environment, temperature rise in a room slows down, and the energy consumption is reduced.

Owner:SHENZHEN DAS INTELLITECH CO LTD

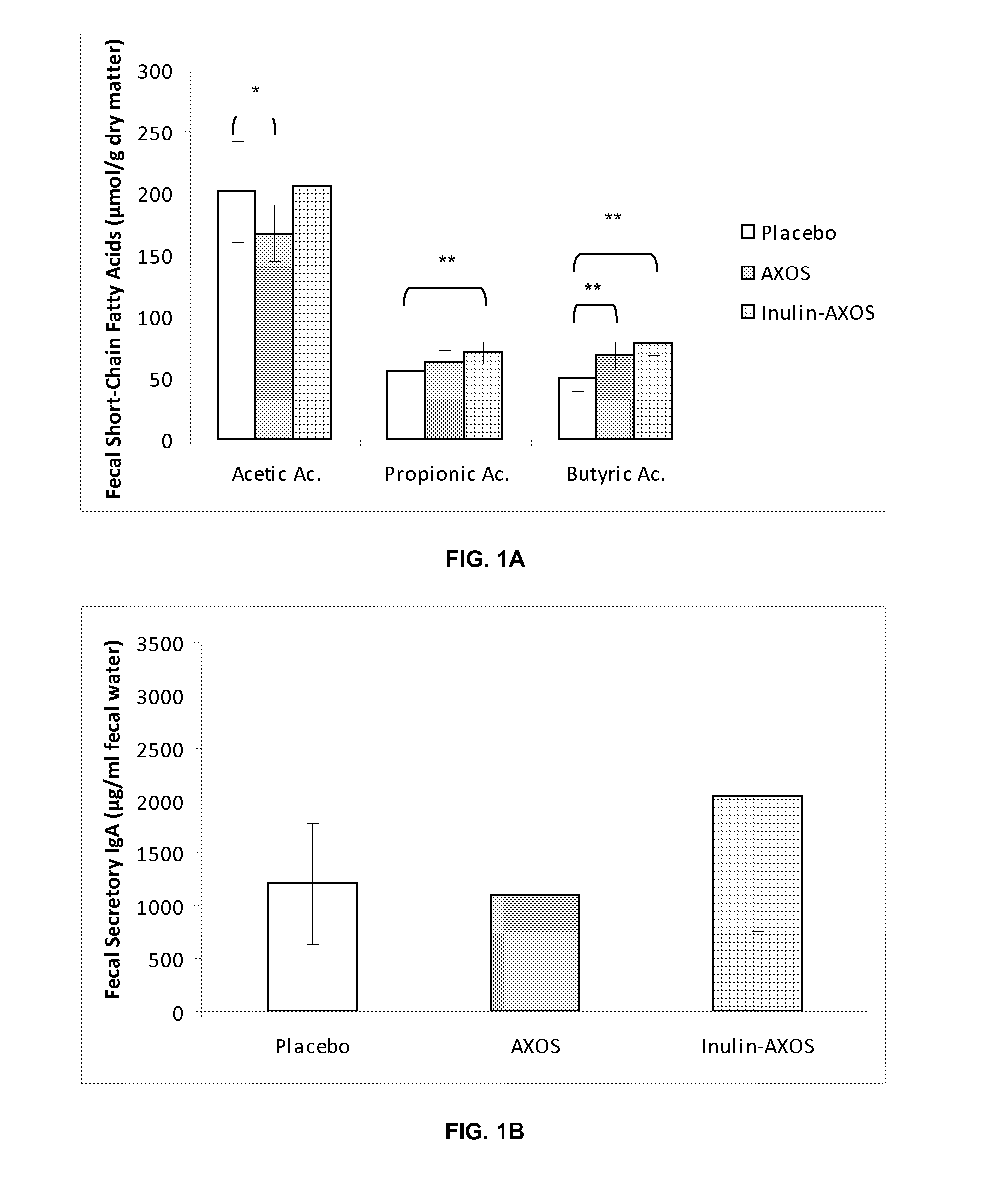

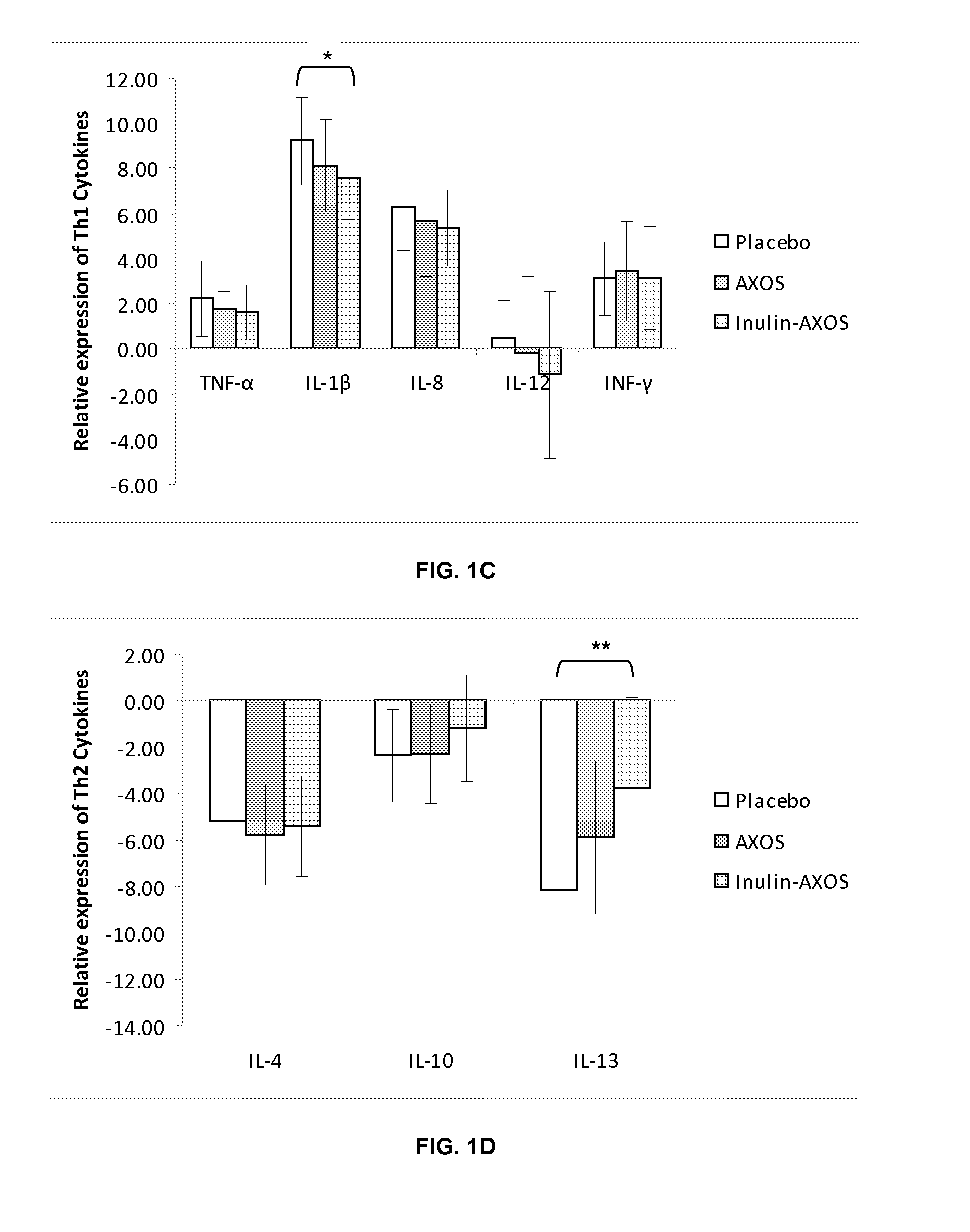

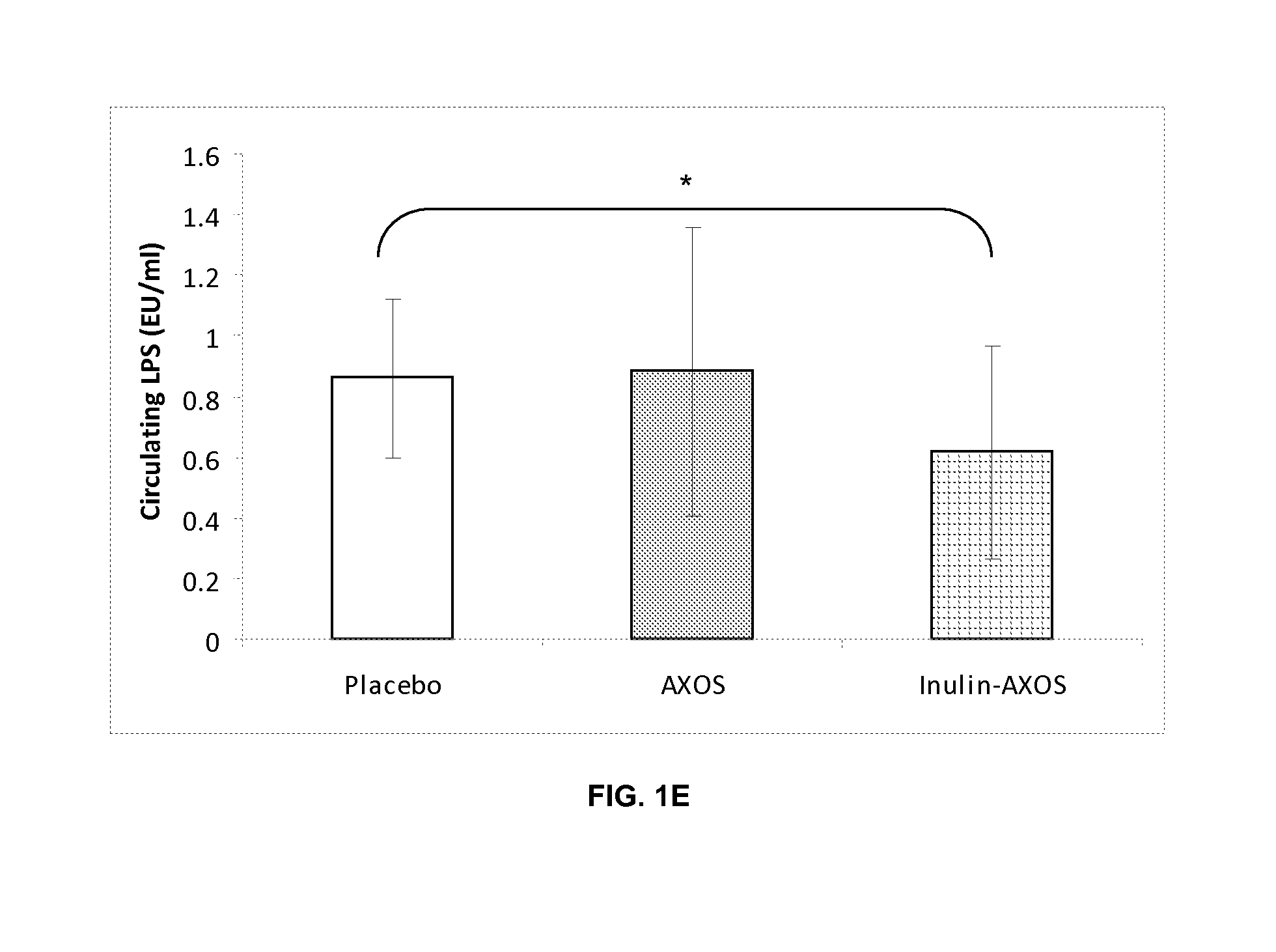

Compositions containing mixtures of fermentable fibers

ActiveUS20120135957A1Reduce and prevent and inflammationImprove the immunityOrganic active ingredientsBiocideArabinoxylanChemistry

The present invention relates to synergistic compositions comprising mixtures of fermentable fibers. The present invention specifically relates to composition comprising inulin and arabinoxylan for use in reducing, preventing and / or treating inflammation, wherein said arabinoxylan is partially hydrolyzed arabinoxylan and wherein the ratio of said inulin to said arabinoxylan and / or partially hydrolyzed arabinoxylan is between 65% / 35% by weight and 90% / 10% by weight.

Owner:COSUCRA GRP WARCOING

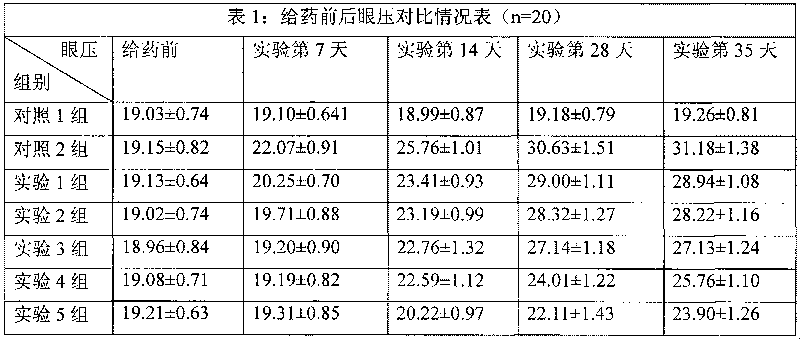

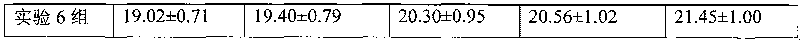

Cyclodextrin inclusion drug composition for ocular inflammation resistance

ActiveCN101757621AAchieve anti-inflammatory effectReduce elevationOrganic active ingredientsSenses disorderVitamin CGlucocorticoid

The invention relates to a cyclodextrin inclusion drug composition for ocular inflammation resistance, which consists of vitamin C or a derivative thereof as an active ingredient, glucocorticoid, cyclodextrin and one or more pharmaceutically acceptable pharmaceutical excipients capable of acting on eyes, wherein the glucocorticoid and / or the derivative of the vitamin C are included by the cyclodextrin.

Owner:TIANJIN JINYAO GRP

Non-fuel medium quenching process for casting grinding ball and casting grinding section

InactiveCN102140572AImprove efficiencyIncrease productivityQuenching agentsWater solubleNational standard

The invention relates to a non-fuel medium quenching process for a casting grinding ball and a casting grinding section, comprising the following operation steps of: firstly, preparing water-soluble quenching liquid with concentration of 10-25 percent, wherein the temperature of the quenching liquid is controlled to be 10-90DEG C; secondly, feeding the casting grinding ball and the casting grinding section in a quenching basket and then in a heating furnace, heating until the quenching temperature is 930-1,150DEG C, discharging from the furnace and uniformly spreading in a movable quenching cradle; thirdly, immersing the movable quenching cradle in the water-soluble quenching liquid of a quenching pond and quenching for 5-10 minutes; and fourthly, when the surface temperature of the casting grinding ball and the casting grinding section is reduced to be 250-350DEG C, finishing quenching operation. By using the process disclosed by the invention, various technical indexes of the casting grinding ball and the casting grinding section are respectively higher than those of current national standard and industrial standard. The quenching hardness is stabilized between 62 and 66HRc (Rockwell hardness) and the difference between the center and the surface hardness is smaller than 1.5HRc. The grinding ball and the grinding section treated by adopting the process disclosed by the invention not only have stable quality and remarkably-reduced cost. Meanwhile, the potential safety hazard of production fields and the pollution to the environment are avoided.

Owner:ANHUI FENGXING WEAR RESISTANT MATERIALS CO LTD

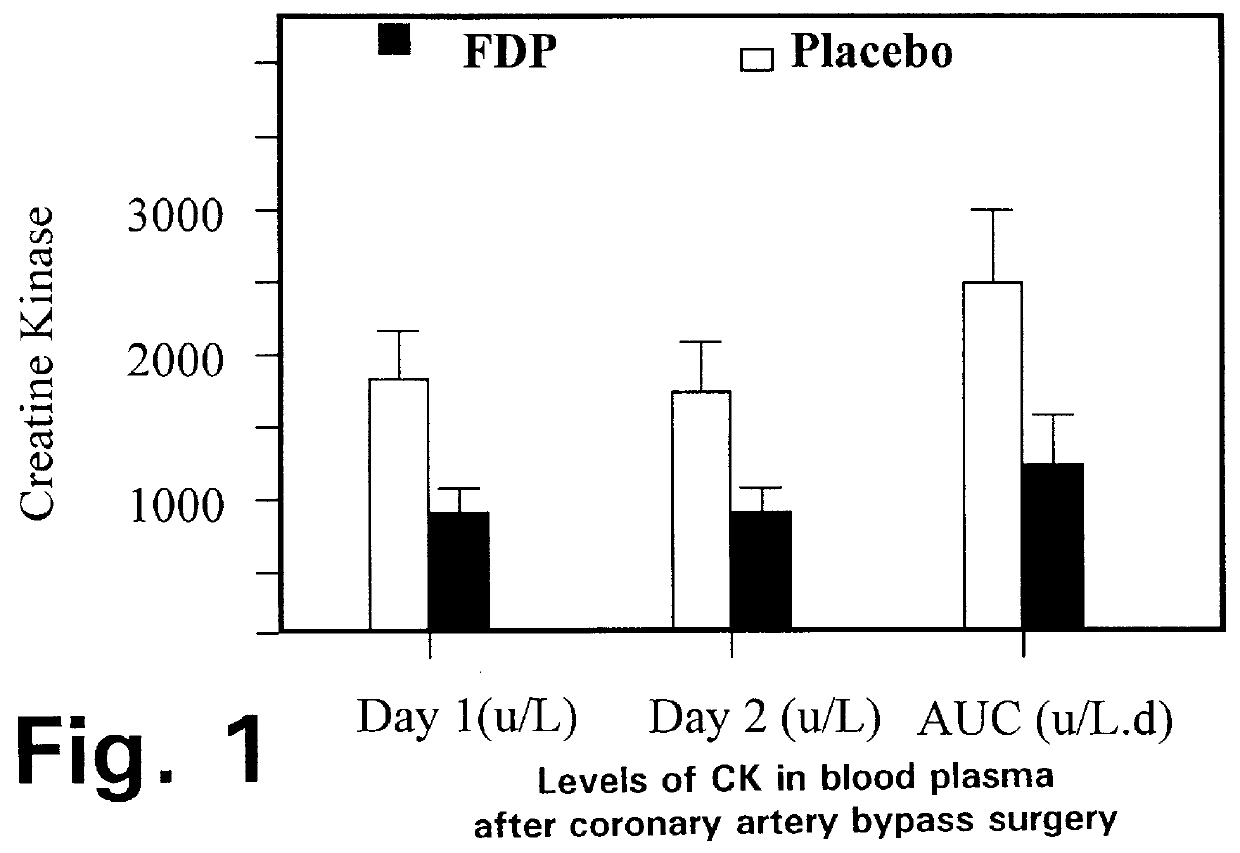

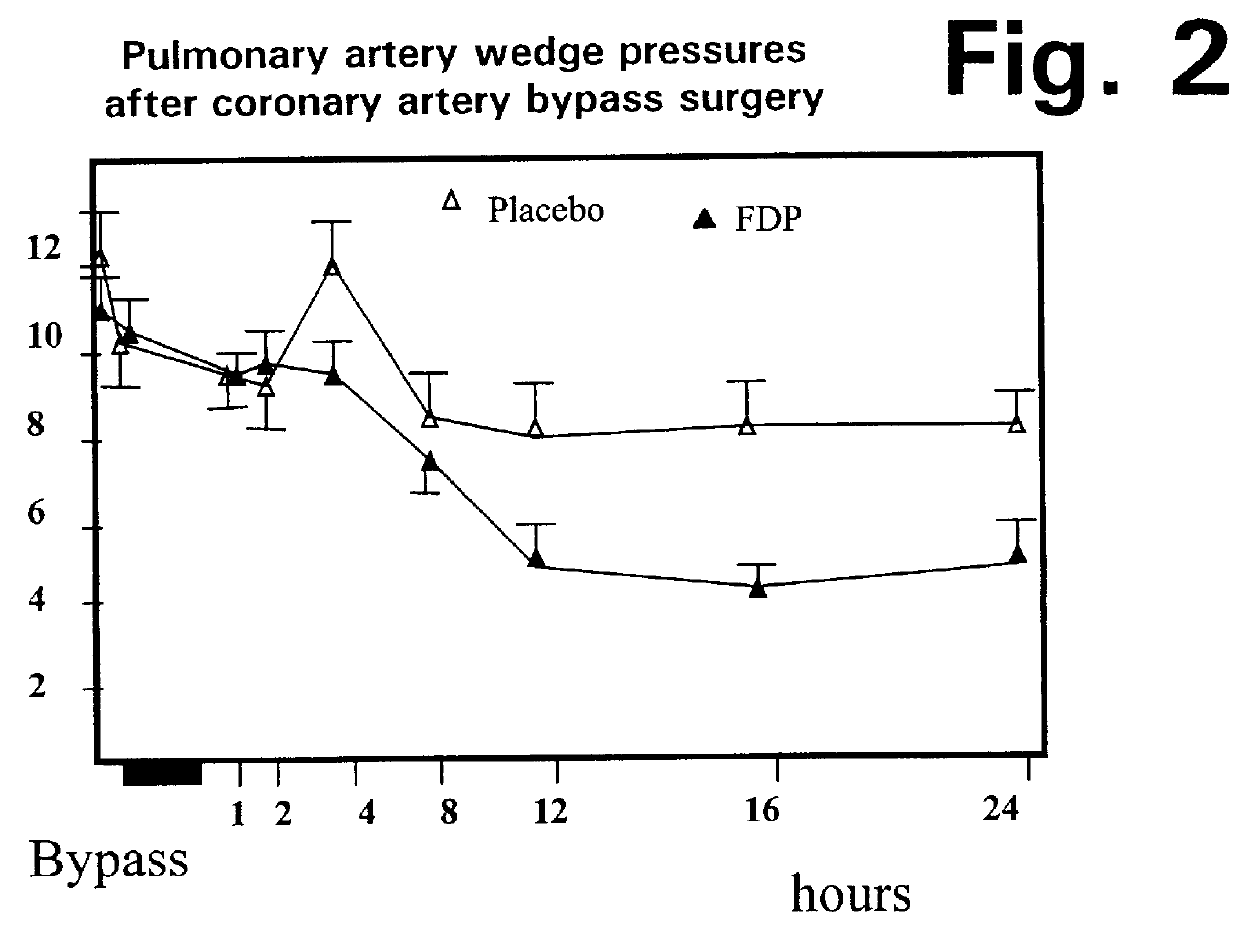

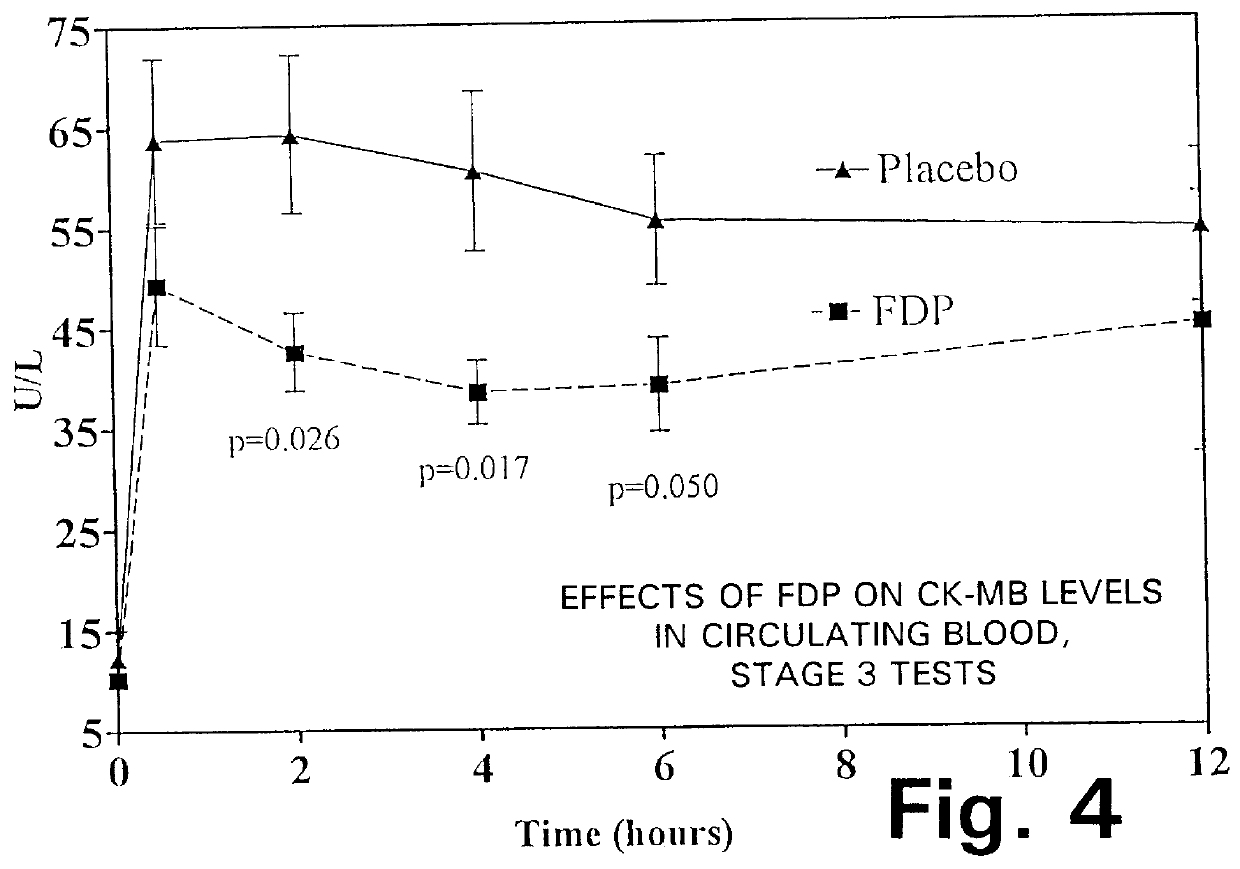

Injection of fructose-1,6-diphosphate (FDP) prior to coronary artery bypass grafting surgery

Fructose-1,6-diphosphate (FDP) is used to treat patients who are undergoing coronary artery bypass grafting (CABG) surgery. Before cardiopulmonary bypass begins, a liquid that contains FDP is intravenously infused in the patient, preferably for about 10 to 30 minutes, to allow the FDP to enter the heart and lung tissue while the heart is still beating. FDP can also be added to cardioplegia solution; in addition, FDP can be injected after bypass is terminated, but if post-bypass injection is used, steps should be taken to avoid excess lactic acid accumulation, which appears to increase the risk of atrial fibrillation. To prevent or control lactic acidosis, a buffering or alkalizing agent, such as sodium bicarbonate, or an agent which reduces lactic acid formation, such as dichloroacetate, can be used. In double-blinded trials, this use of FDP substantially reduced heart damage and improved overall outcomes, as shown by lower levels of creatine kinase in blood, improvements in pumping performance, reduced requirements for vasodilator and inotropic drugs, and shorter stays in intensive care units. Certain dosages also reduced the likelihood of atrial fibrillation; however, FDP at high dosages increased the likelihood of A-fib. FDP also helped reduce pulmonary vascular resistance (PVR); this is an important finding, since pulmonary hypertension following cardiopulmonary bypass is a very difficult and often intractable problem, and is a contributing factor in nearly all deaths following CPB surgery.

Owner:QUESTCOR PHARMA

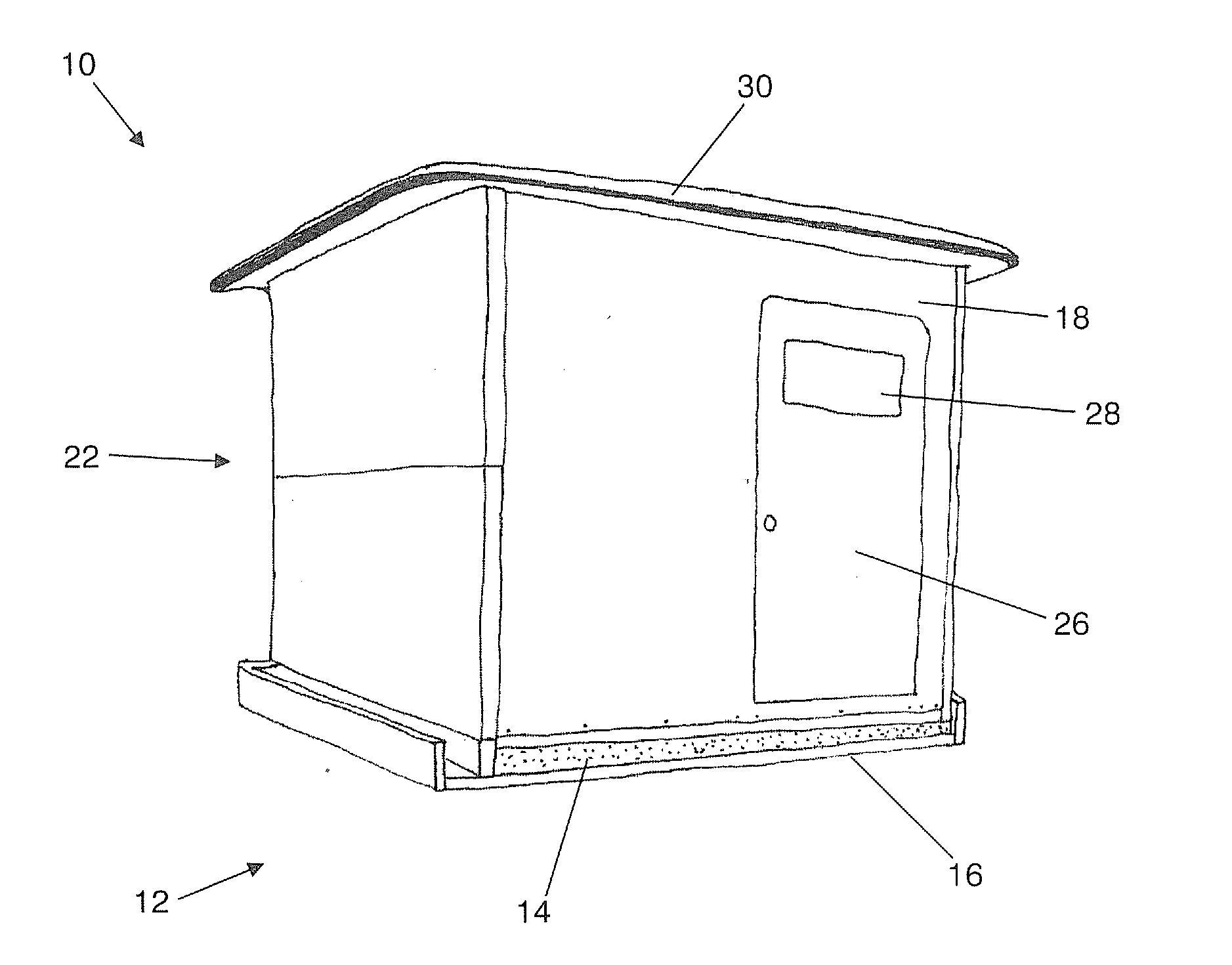

Portable sleeping assembly

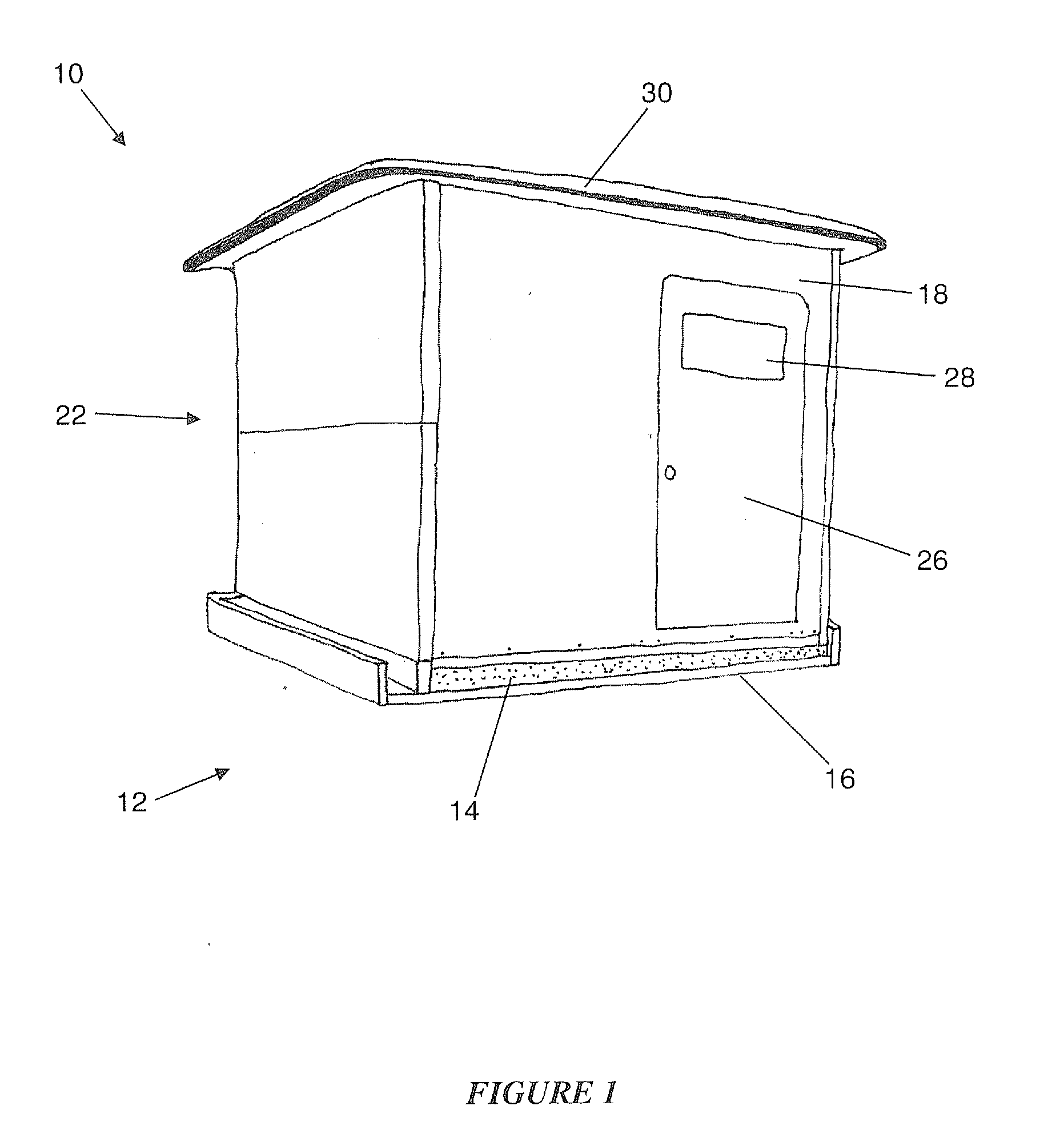

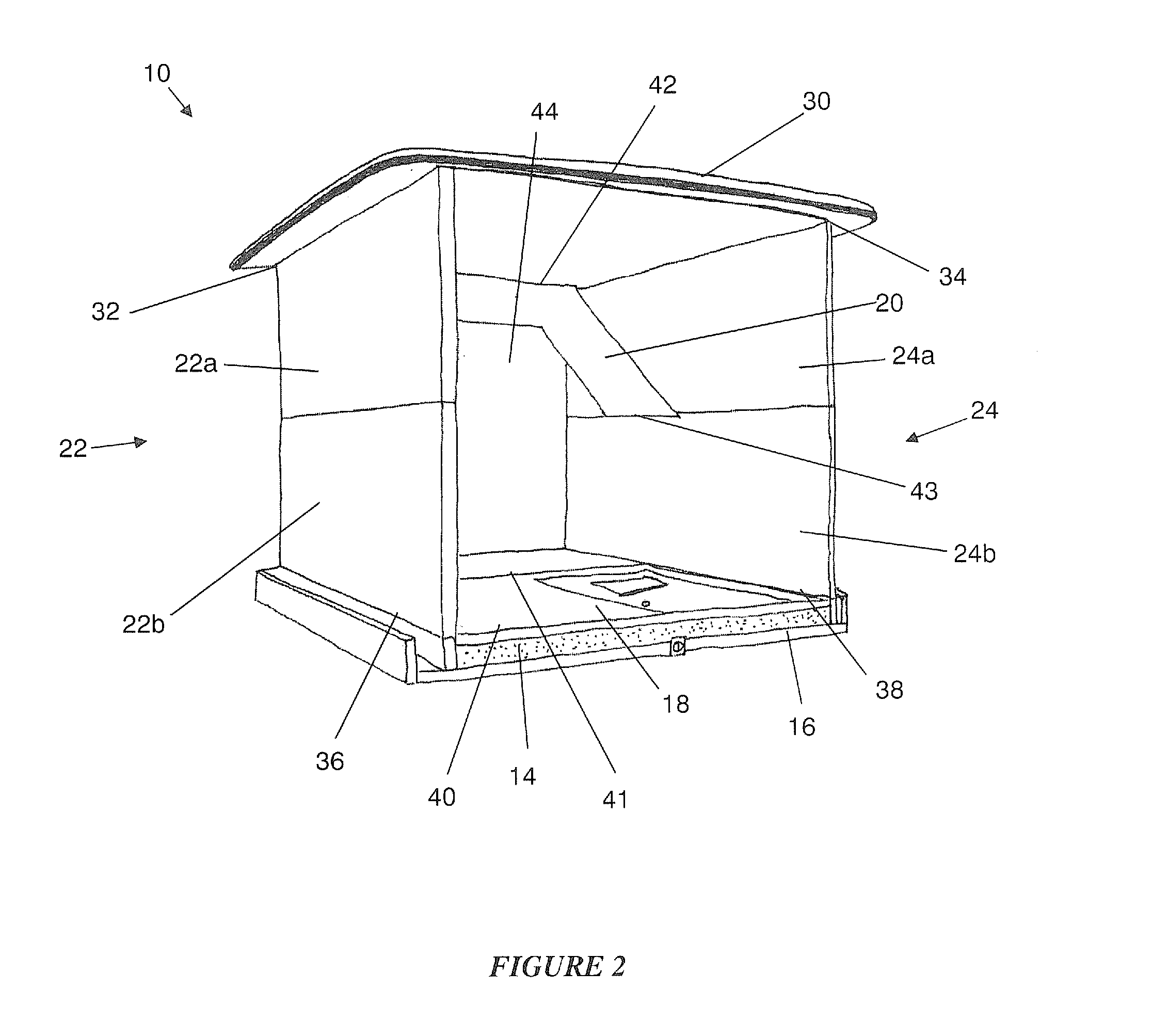

InactiveUS20140251401A1Eliminate troubleIncreased protection and insulationTents/canopiesVehicle with living accommodationEngineeringMechanical engineering

The present invention is directed to a portable sleeping assembly. The portable sleeping assembling includes a base for removably mounting to transport, one or more walls extending from the base, each wall including one or more rigid panels, and a roof from which the one or more walls extend such that movement of the one or more walls moves the roof relative to the base.

Owner:PATPRO QLD

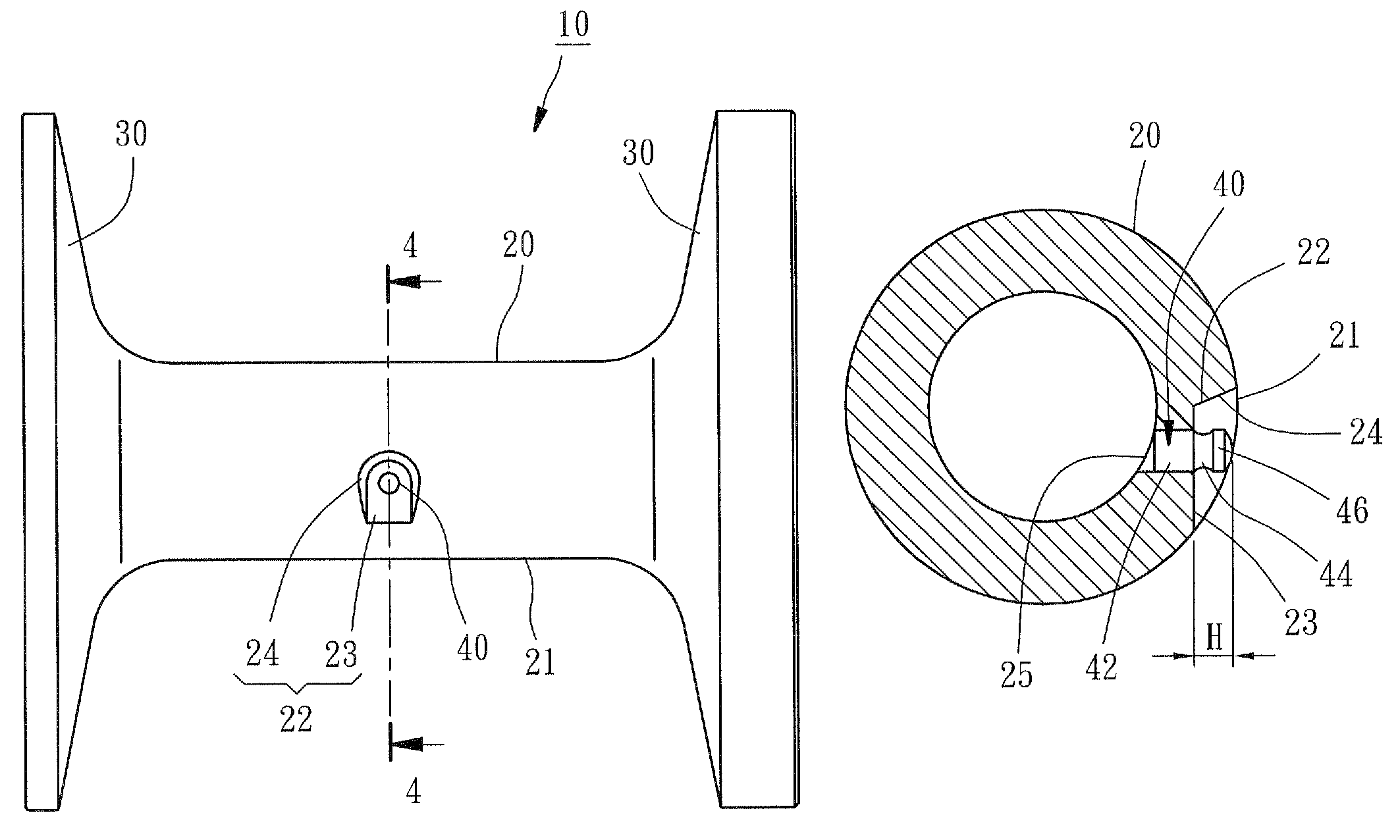

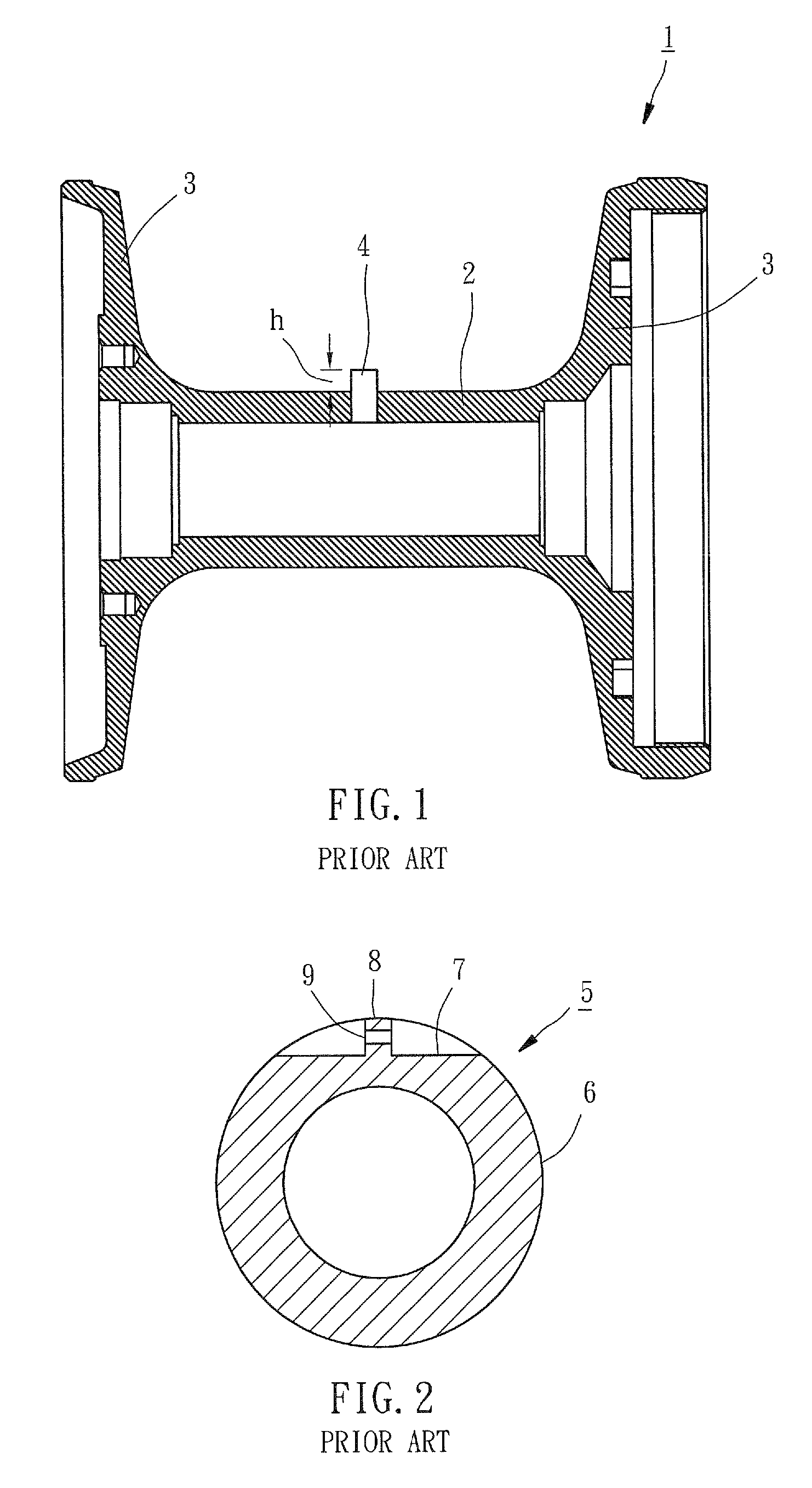

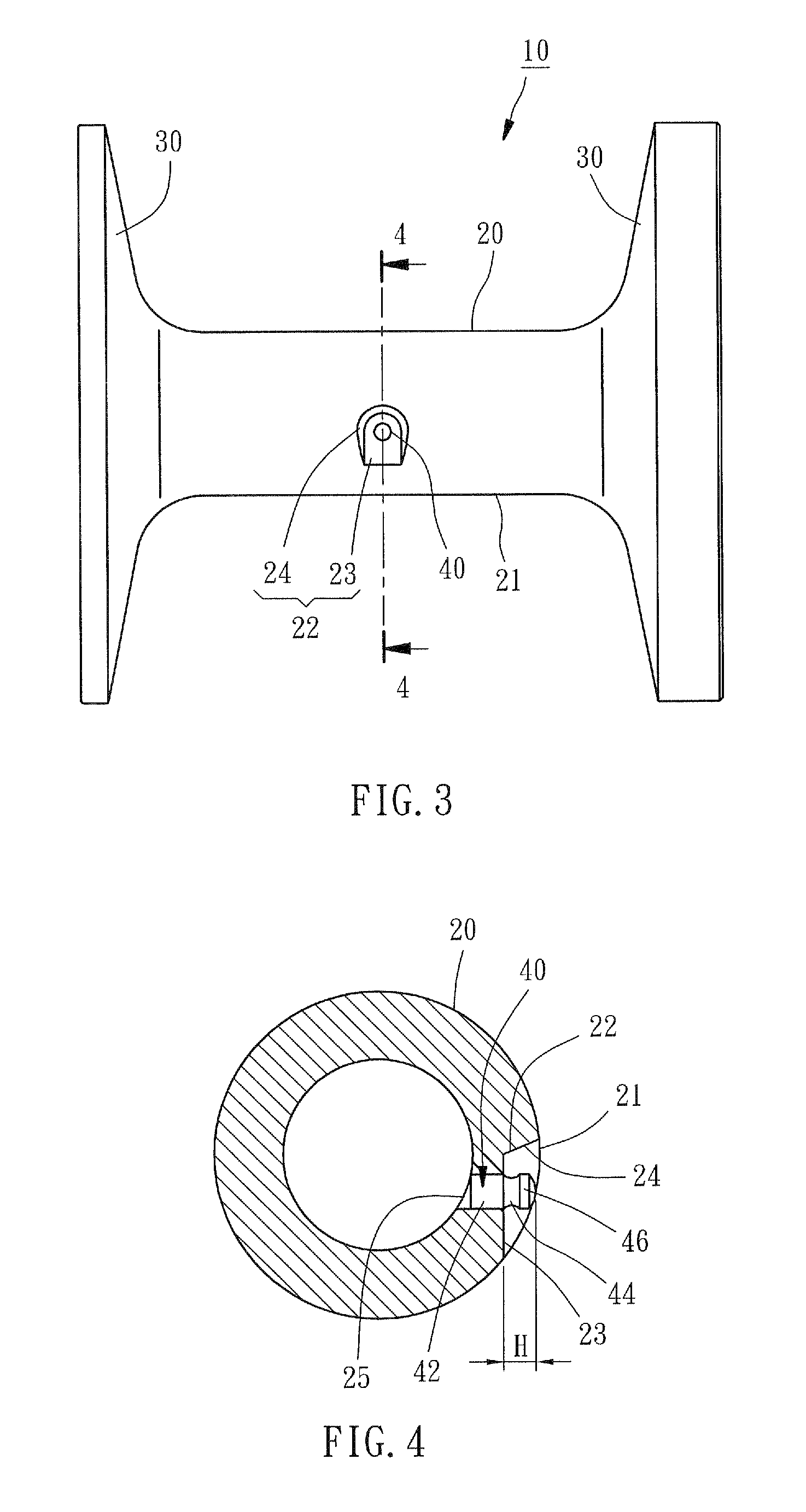

Spool for fishing reel

InactiveUS7490790B1Prevents unsmooth operationPositive fixationReelsWebs handlingEngineeringFishing lure

A spool for a fishing reel is disclosed to include an axle, which has a surface and a recess curved inwards from the surface, two sidewalls radially extending from the two distal ends of the axle, and a pin, which is disposed in the recess with the topmost edge thereof kept in flush with the surface of the axle for the fastening of a fishing line for allowing the spool to take up or let off the fishing line smoothly.

Owner:OKUMA FISHING TACKLE

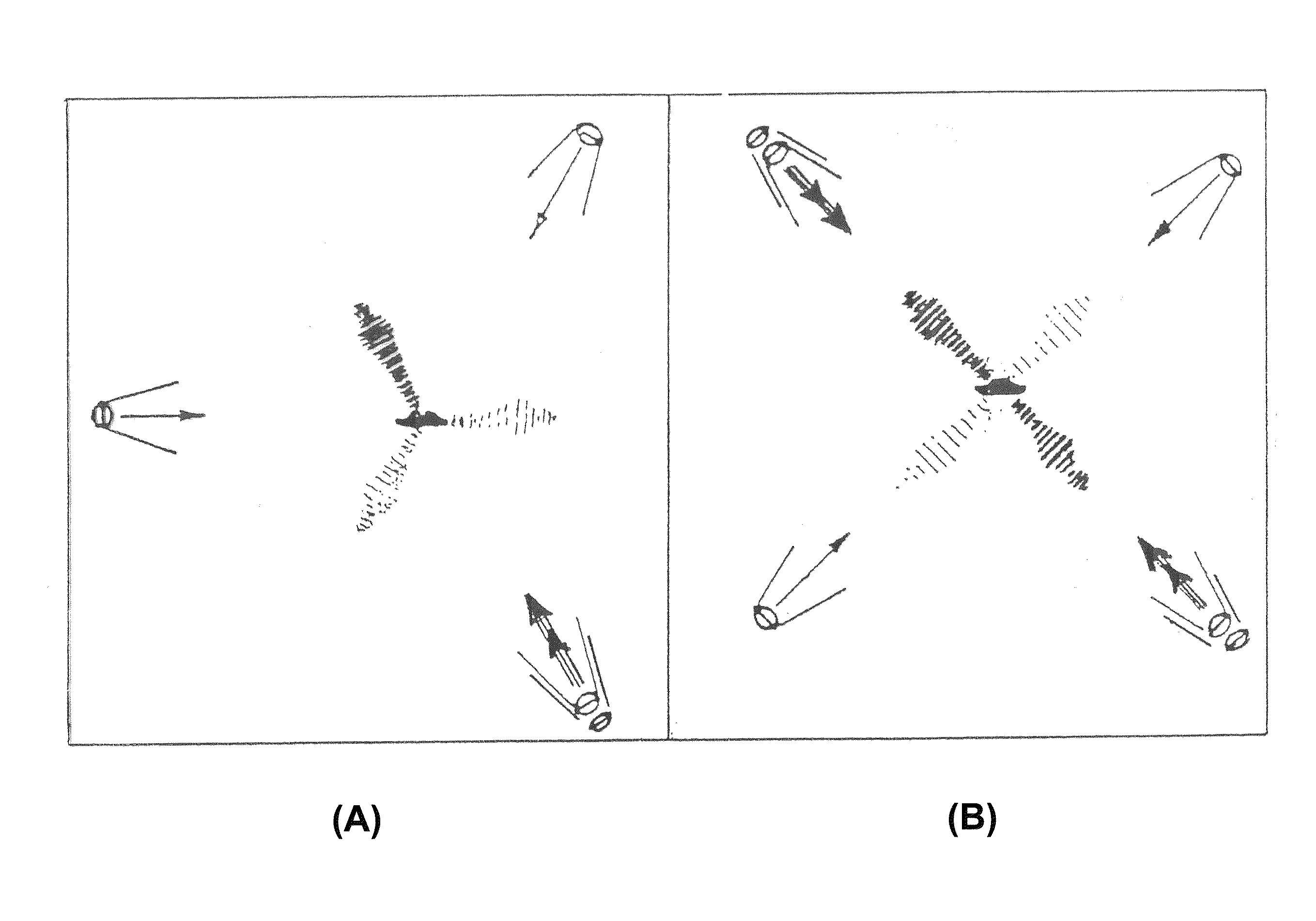

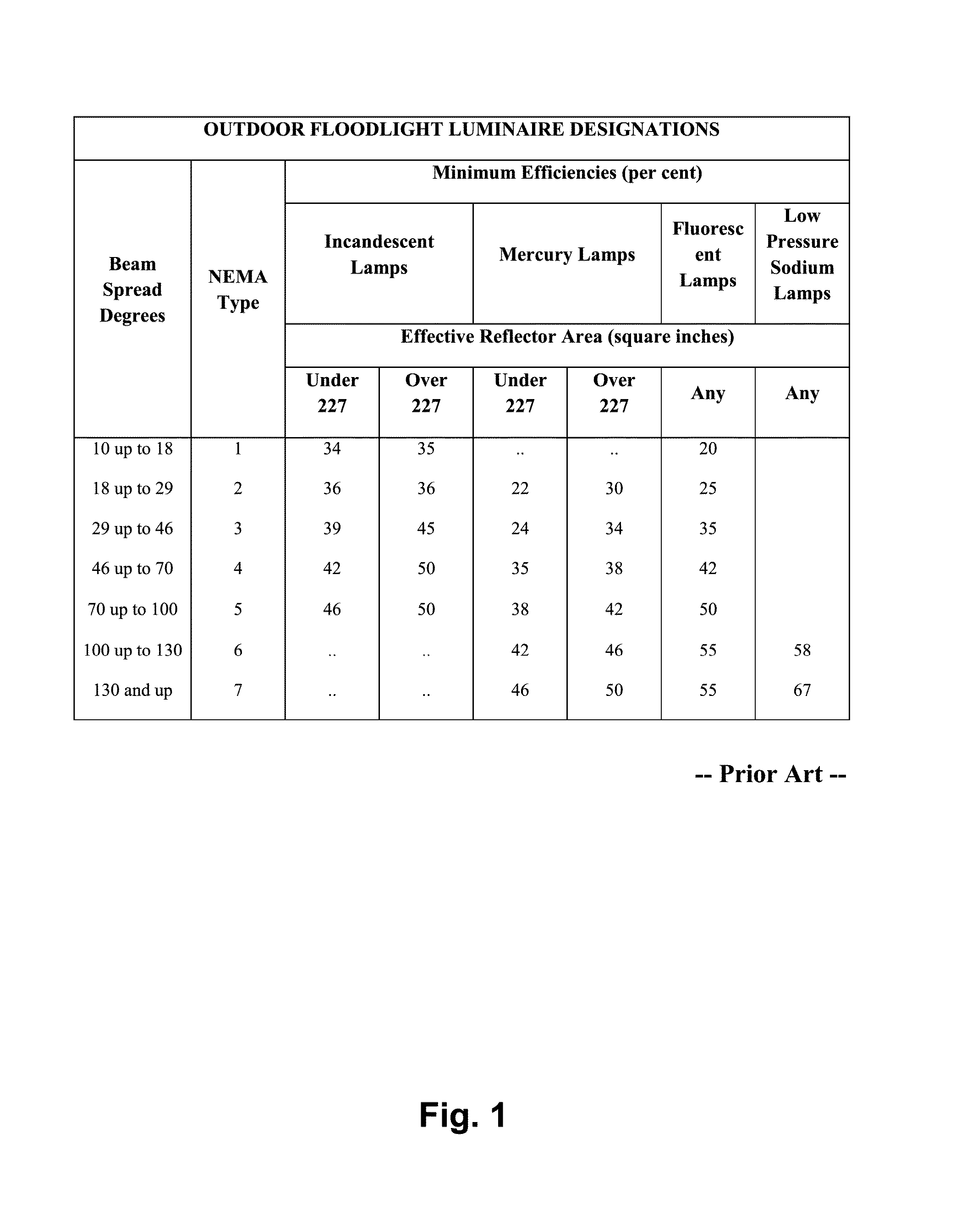

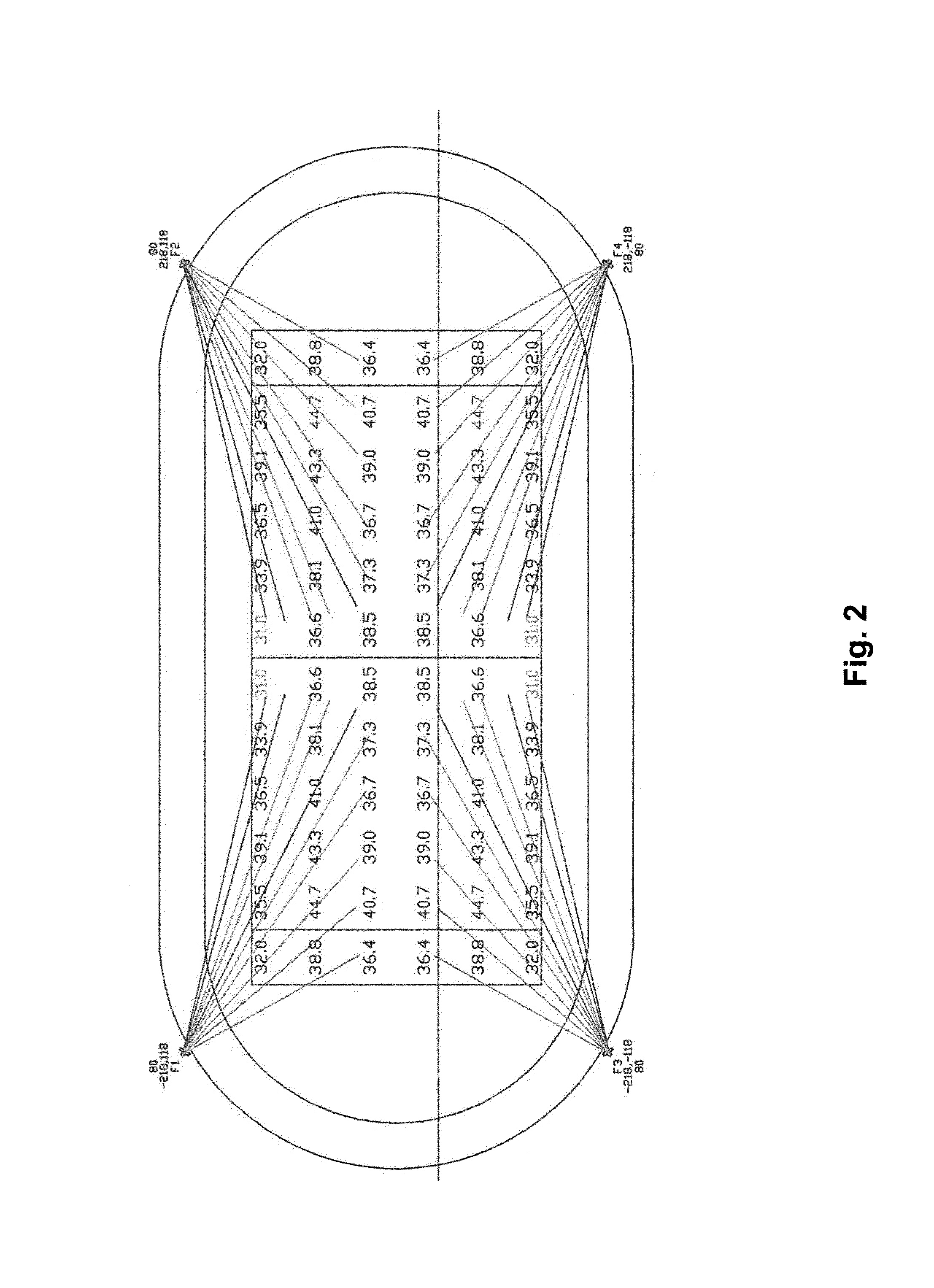

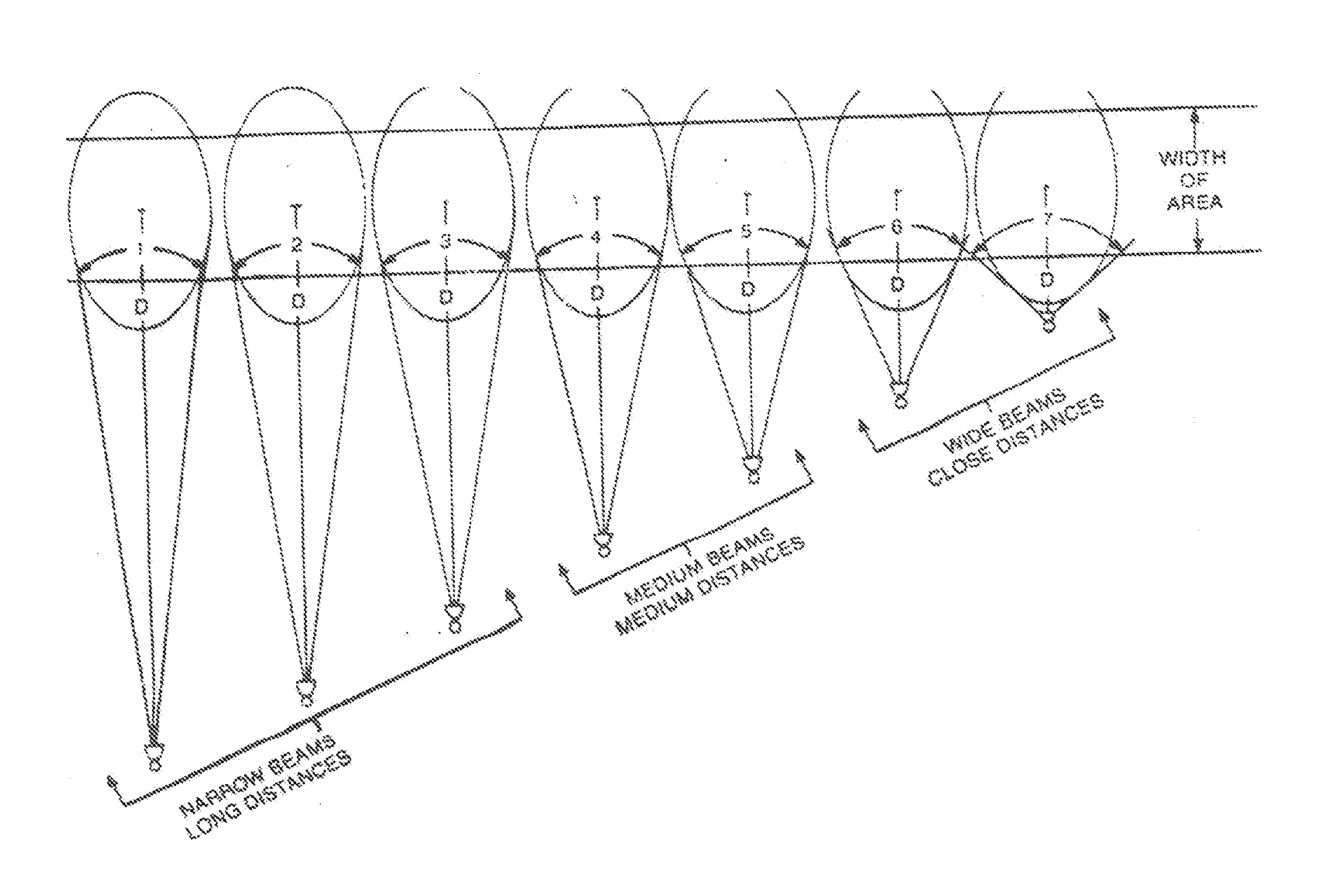

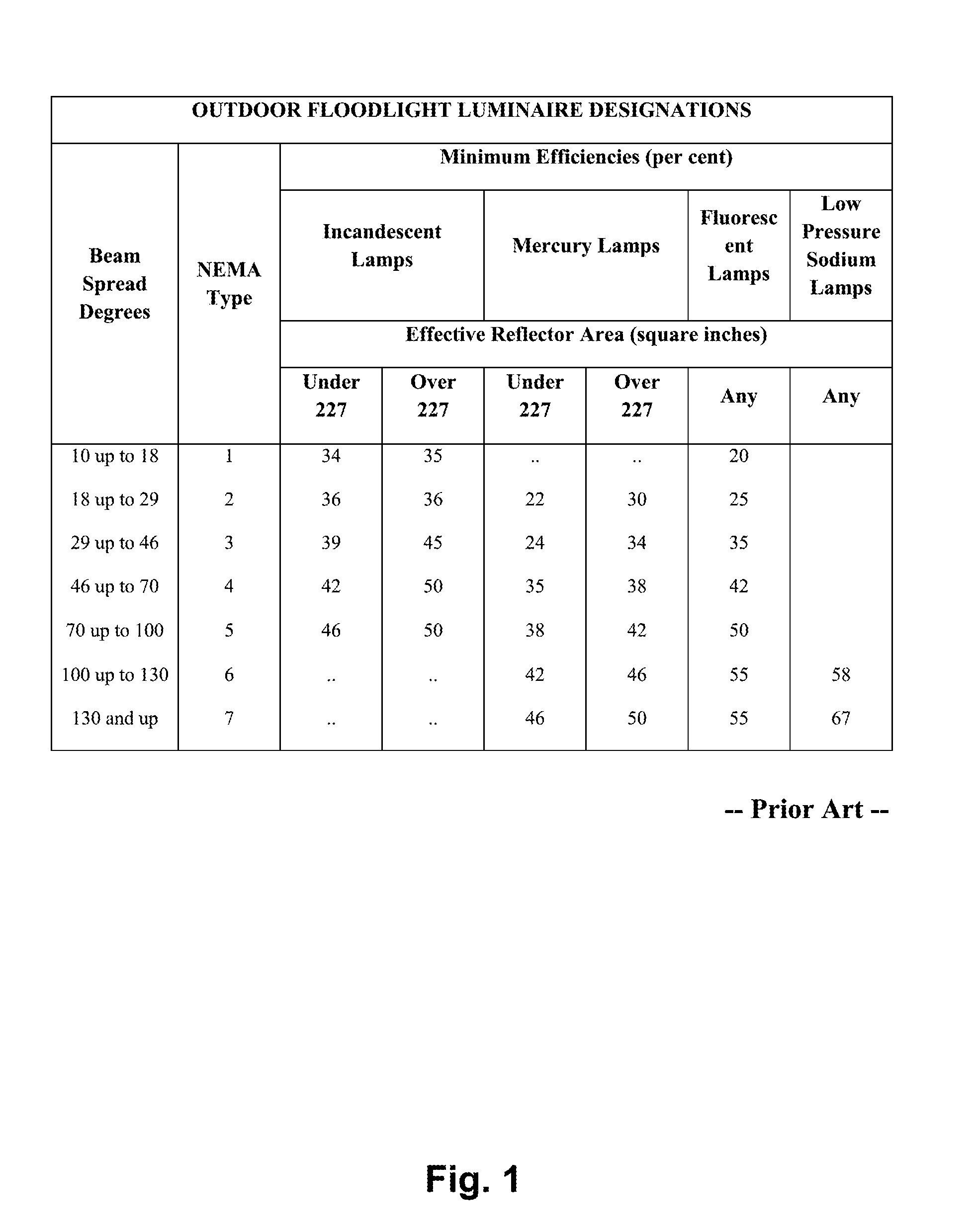

Light emitting diode (LED) sports lighting luminaire assembly

InactiveUS9206950B1Controlling glareLighting is limitedMechanical apparatusLighting support devicesEngineeringLED lamp

An assembly of LED luminaires is distributed at a sports venue, includes key, back, and fill light sources in such a way as to provide modeling within a significant portion of the playing area of the sports venue, uses beam types narrower than previously used, and achieves efficiencies higher than previously attained, while also reducing glare and spill light.

Owner:T&S LIGHTING SOLUTIONS

Six-degree-of-freedom motion simulator assembly

ActiveUS9842509B2Improve the forceIncrease gravityCosmonautic condition simulationsMechanical order telegraph apparatusDegrees of freedomEngineering

The invention is directed to a 6 degree-of-freedom motion hexapod simulator assembly comprising of a fixed base, a displaceable simulator platform comprising of a load bearing structure, and 6 linear actuators having upper ends thereof interconnected with the load bearing structure by three pairs of two-degree of freedom joints and lower ends thereof interconnected with the fixed base by means of three pairs of two-degree of freedom joints. The two degree of freedom joint comprises of two rotatable pivot means which are oriented 90° with respect to each other. One pivot means runs through the other pivot means. At the connection with the load bearing structure the center of one joint of a pair of joints is separated by part of the load bearing structure from the center of the other joint of the pair of joints.

Owner:E2M TECH

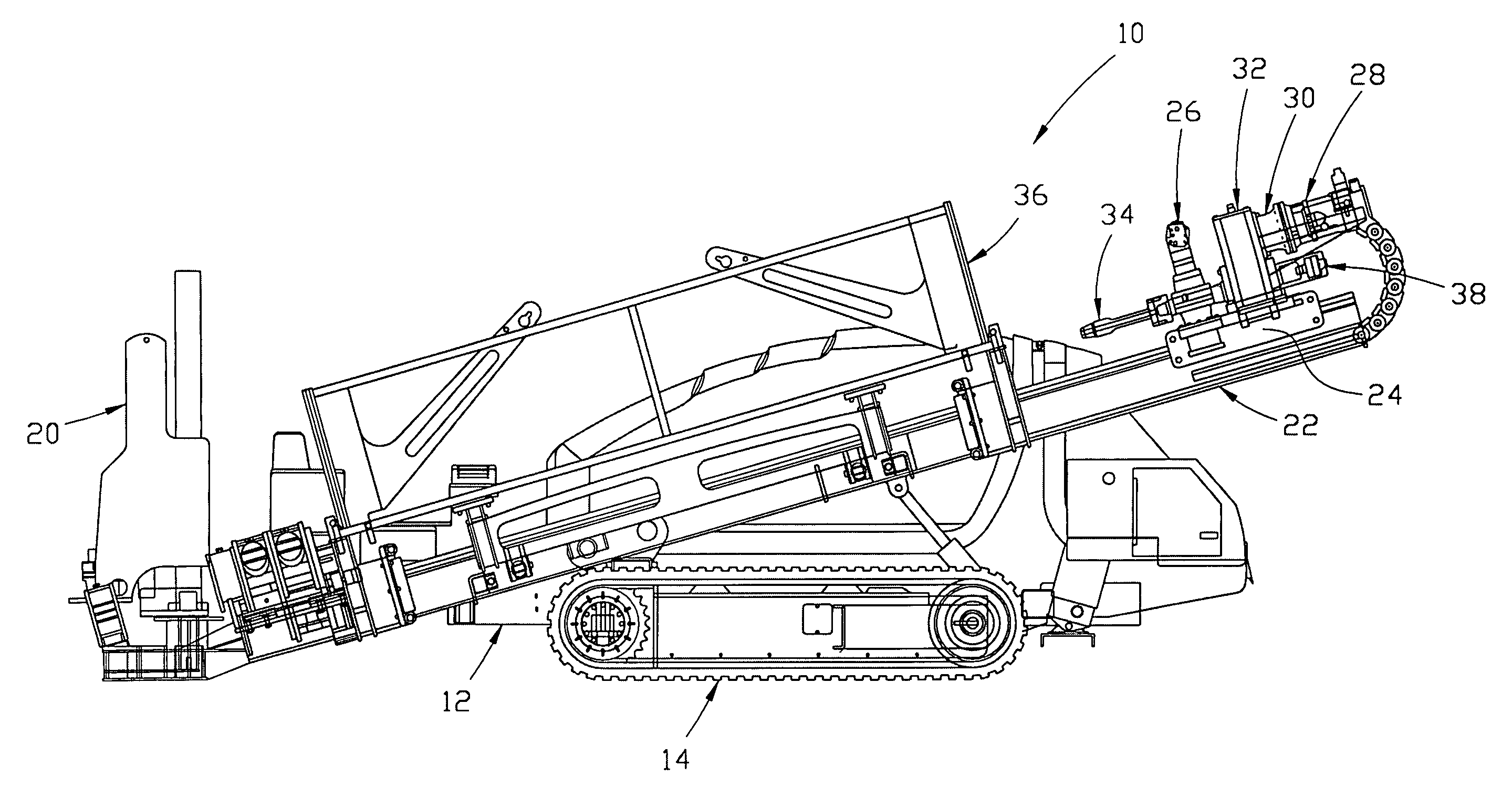

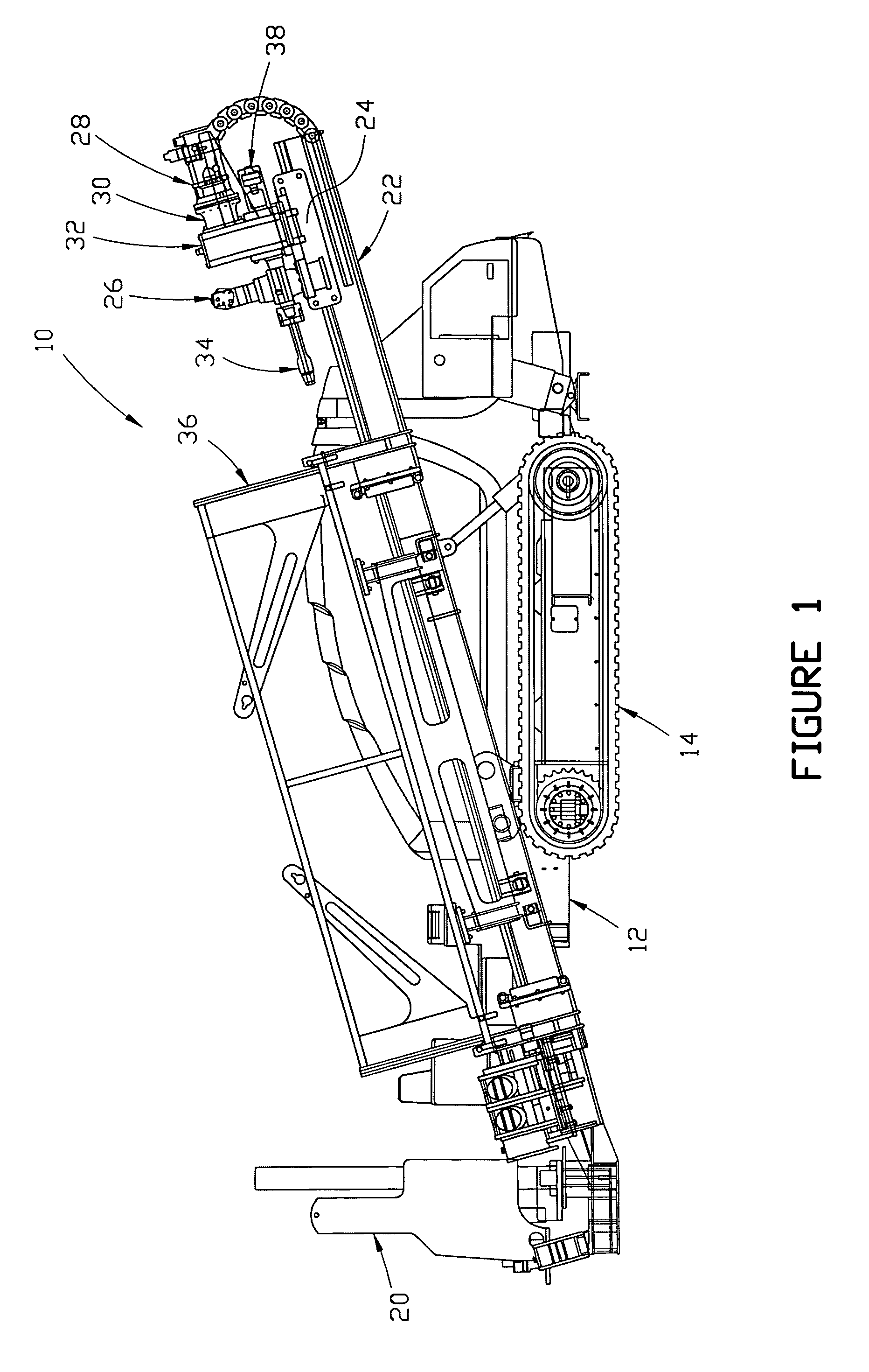

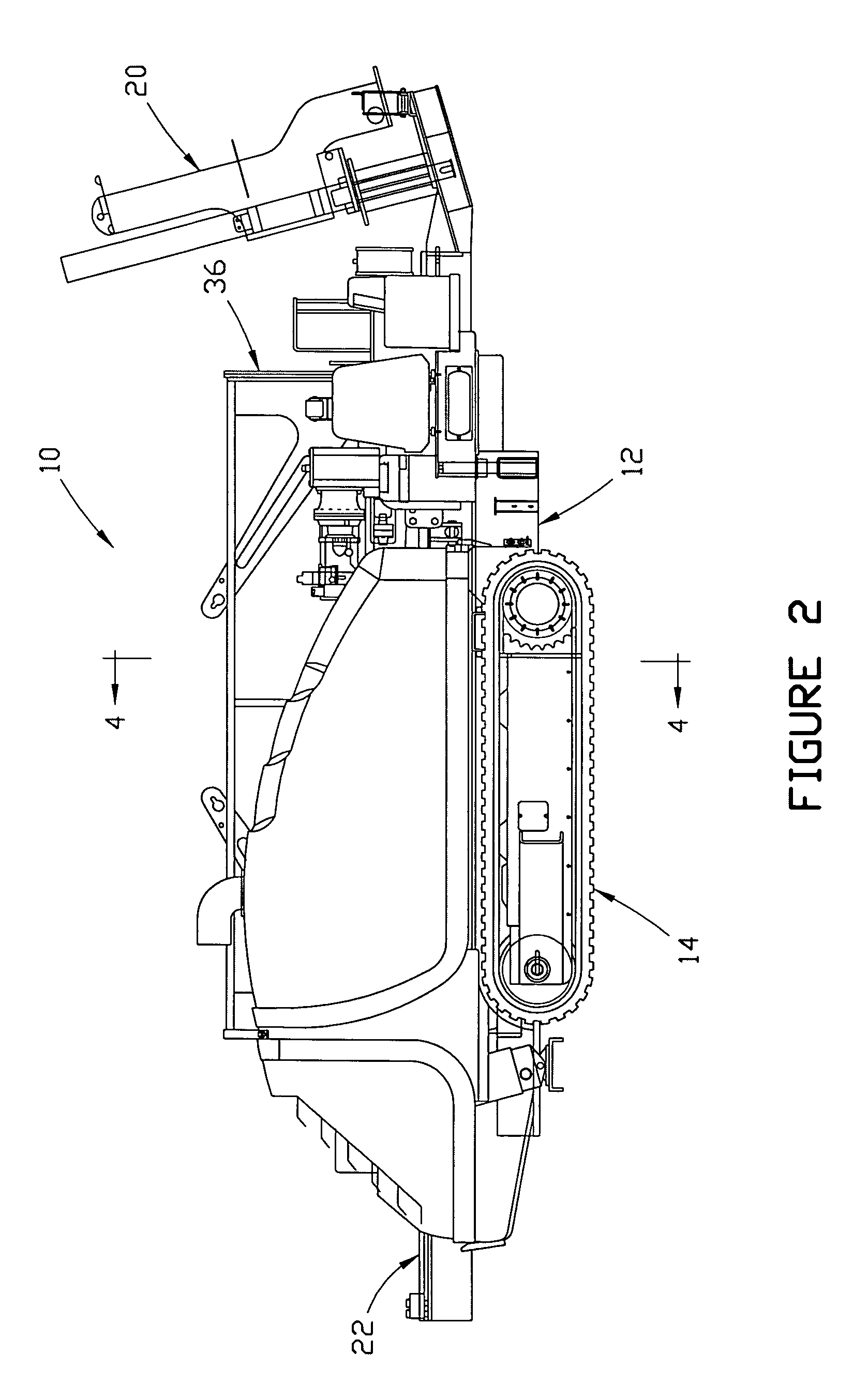

Hydraulic fluid tank for drilling machine

InactiveUS7497274B1Interference minimizationRaise the center of massDrilling rodsReciprocating drilling machinesWell drillingFuel tank

A hydraulic fluid tank for a drilling machine includes a primary chamber and a secondary chamber. The primary chamber is located entirely below the hydraulic pump of the drilling machine, and the secondary chamber is located above and in fluid communication with the primary chamber. The secondary chamber is adapted to maintain a hydraulic fluid level that is above the pump suction centerline of the drilling machine pump as the hydraulic fluid in the tank reaches its normal operating temperature during operation of the drilling machine. The secondary chamber is also sized and configured to allow for thermal expansion of hydraulic fluid in the amount of at least about 5% of the total tank volume as the hydraulic fluid in the tank reaches its normal operating temperature during operation of the drilling machine.

Owner:ASTEC INDS

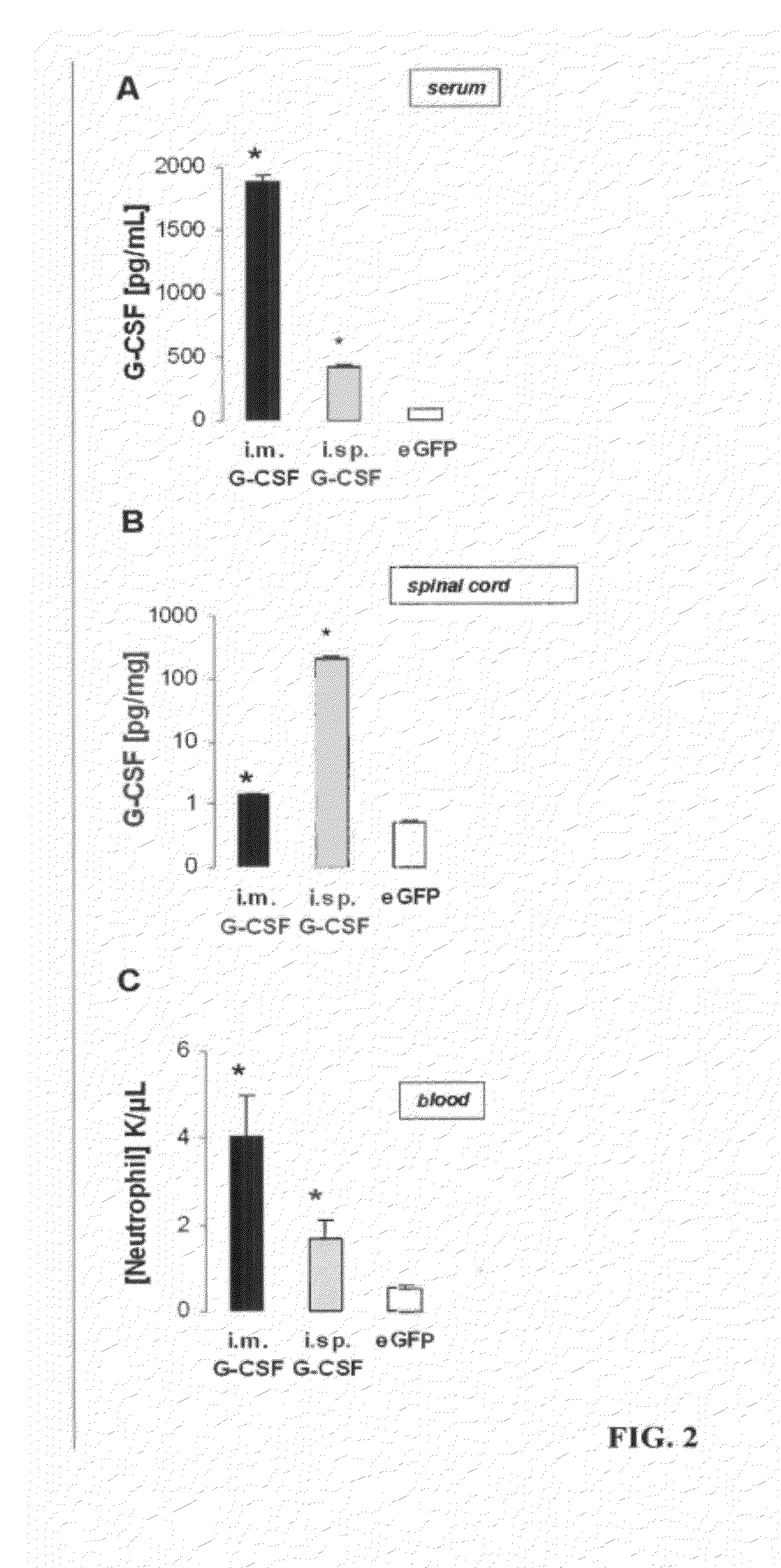

Targeted delivery of g-csf for the treatment of amyotrophic lateral sclerosis

InactiveUS20120141420A1Good curative effectDecreased peripheral loadBiocideNervous disorderAdeno associate virusAdeno-associated virus

The present invention relates to a method of treating Amyotrophic Lateral Sclerosis by the targeted delivery of granulocyte-colony stimulating factor to the central nervous system with an adeno-associated virus (AAV) vector.

Owner:SYGNIS BIOSCIENCE GMBH & CO KG

Compositions and methods for obesity, diabetes and metabolic syndrome control and management

InactiveUS20100247686A1Reduce the amount requiredEffective agent obesityBiocideMetabolism disorderCalorie intakeYerba santa extract

The invention relates to compositions and methods for controlling food, energy, and calorie intake a combination of a Mulberry leaf extract and CissusQuadrangularis extract or plant powder.

Owner:NATUREGEN

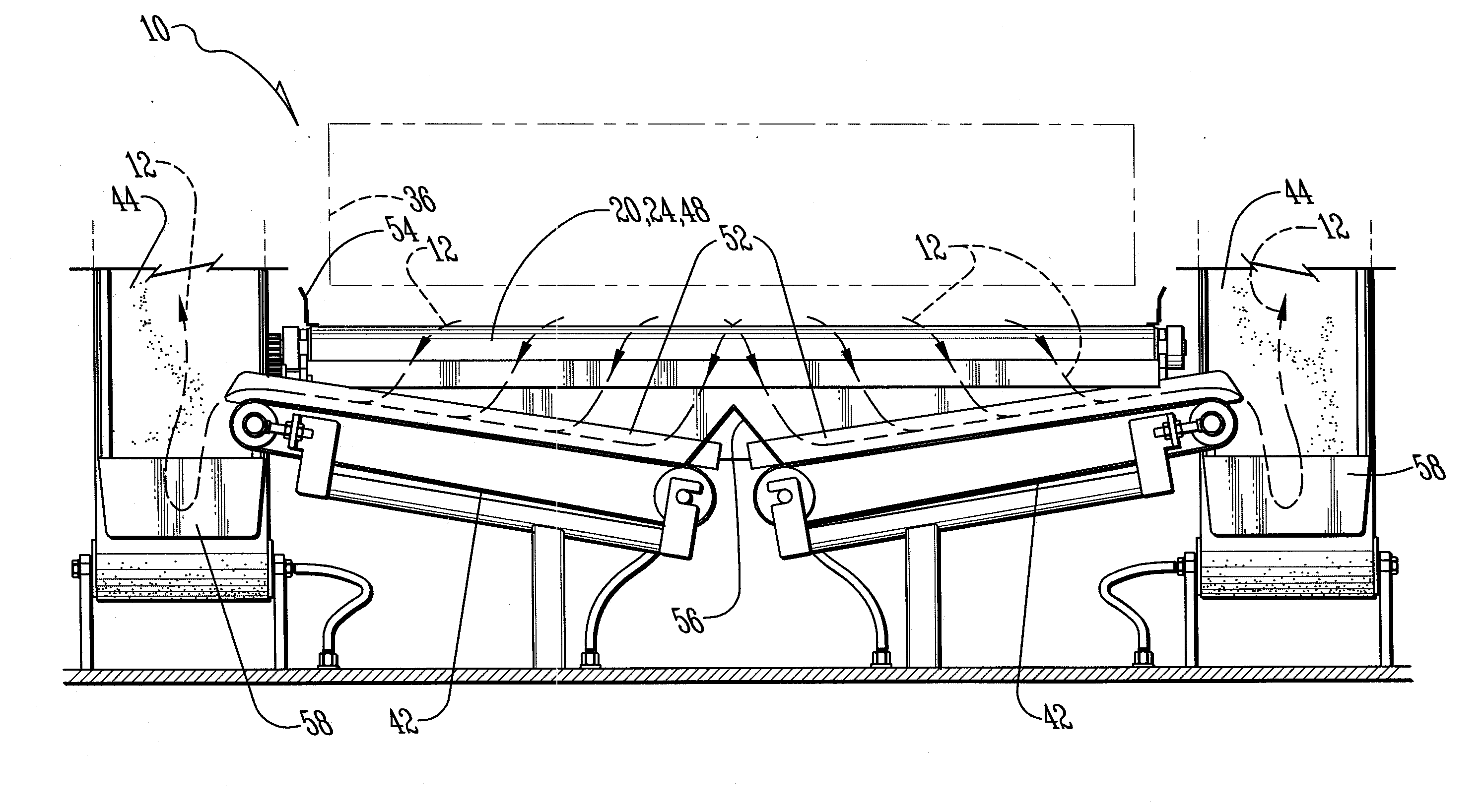

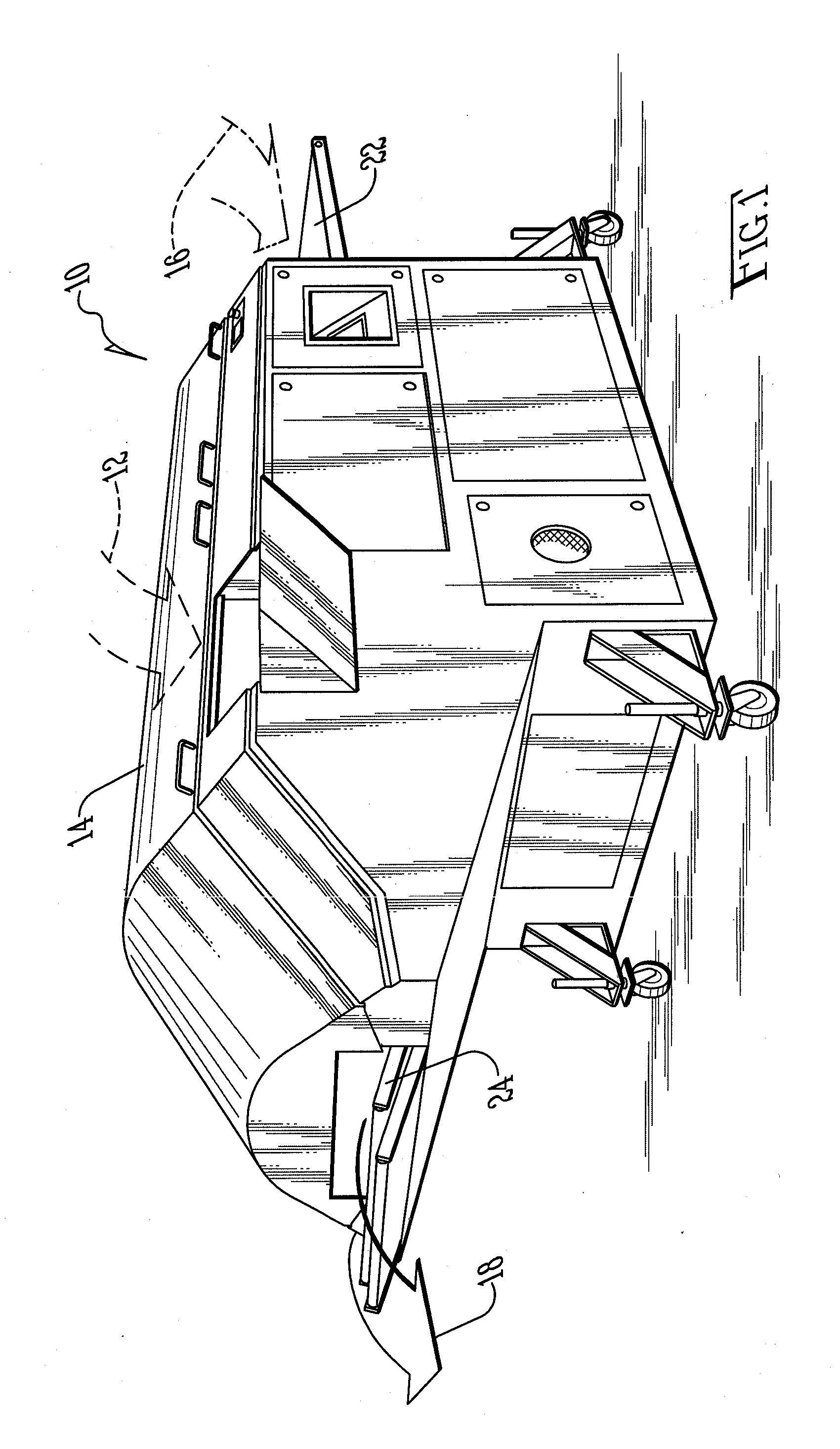

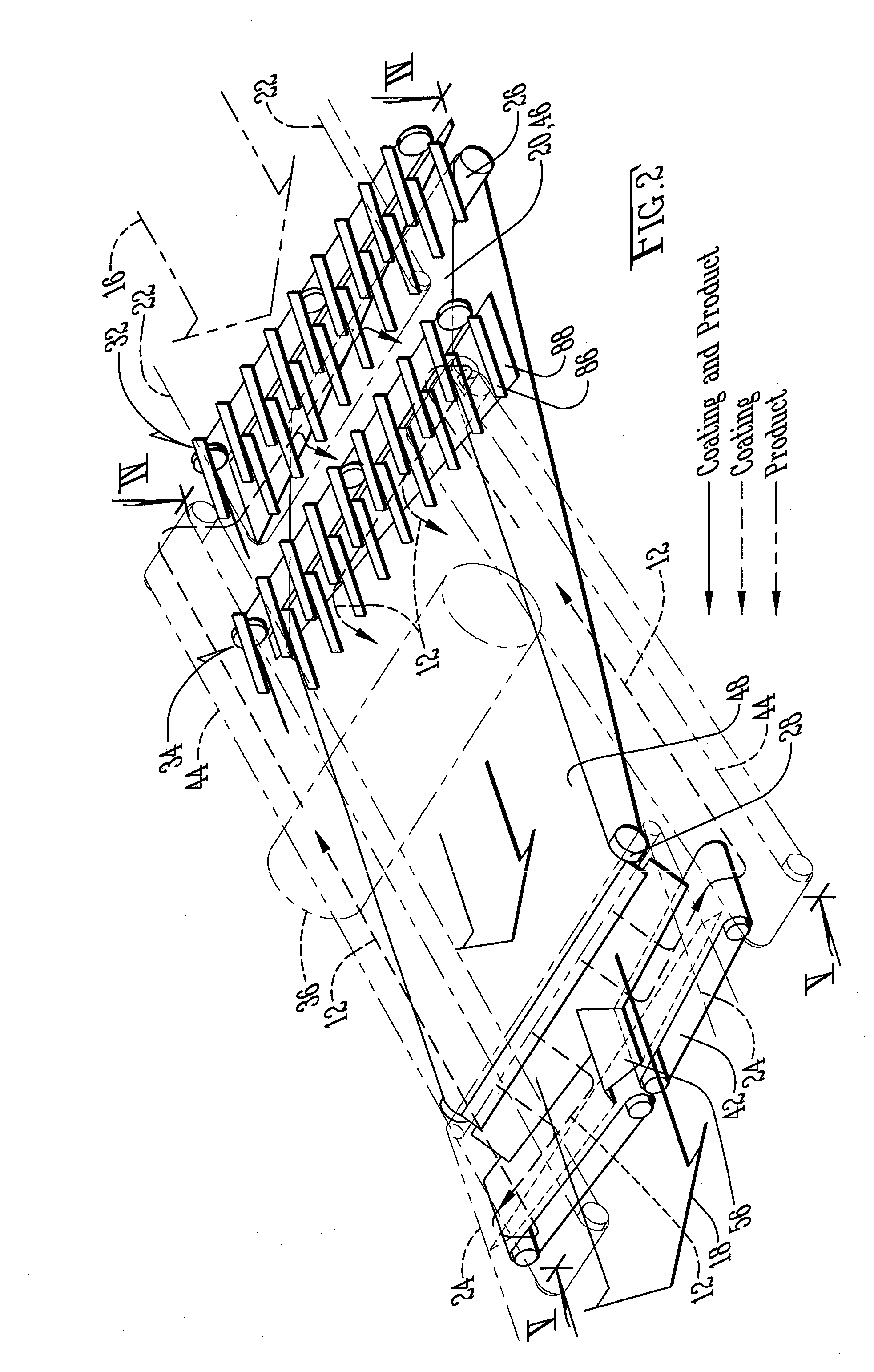

Food product coating apparatus for panko crumb and the like

ActiveUS20150047557A1Discharge fullyWork lessLiquid surface applicatorsFood coatingCounter flowMechanical engineering

A food product coating apparatus has a main conveyor, a coating-material spreading system for spreading coating material across the main conveyor, and a coating-material recirculation system for recirculating excess-coating material spilling out the discharge end of the main conveyor. The recirculation system has at least one transverse collection conveyor and at least one counter-flow return conveyor, both of which like the main conveyor made of solid web material. The coating-material spreading system comprises a first overhead sifting loader near the intake end and a spaced away second overhead sifting loader. A food-product inflow conveyor transfers an inflow of food product to the main conveyor between the first and second loaders.

Owner:NOTHUM JR ROBERT G

Light emitting diode (LED) sports lighting luminaire assembly

InactiveUS20150077995A1High utilization factorReduce energy requirementMechanical apparatusElectrical apparatusLight sourceEngineering

An assembly of LED luminaires is distributed at a sports venue, includes key, back, and fill light sources in such a way as to provide modeling within a significant portion of the playing area of the sports venue, uses beam types narrower than previously used, and achieves efficiencies higher than previously attained, while also reducing glare and spill light.

Owner:T&S LIGHTING SOLUTIONS

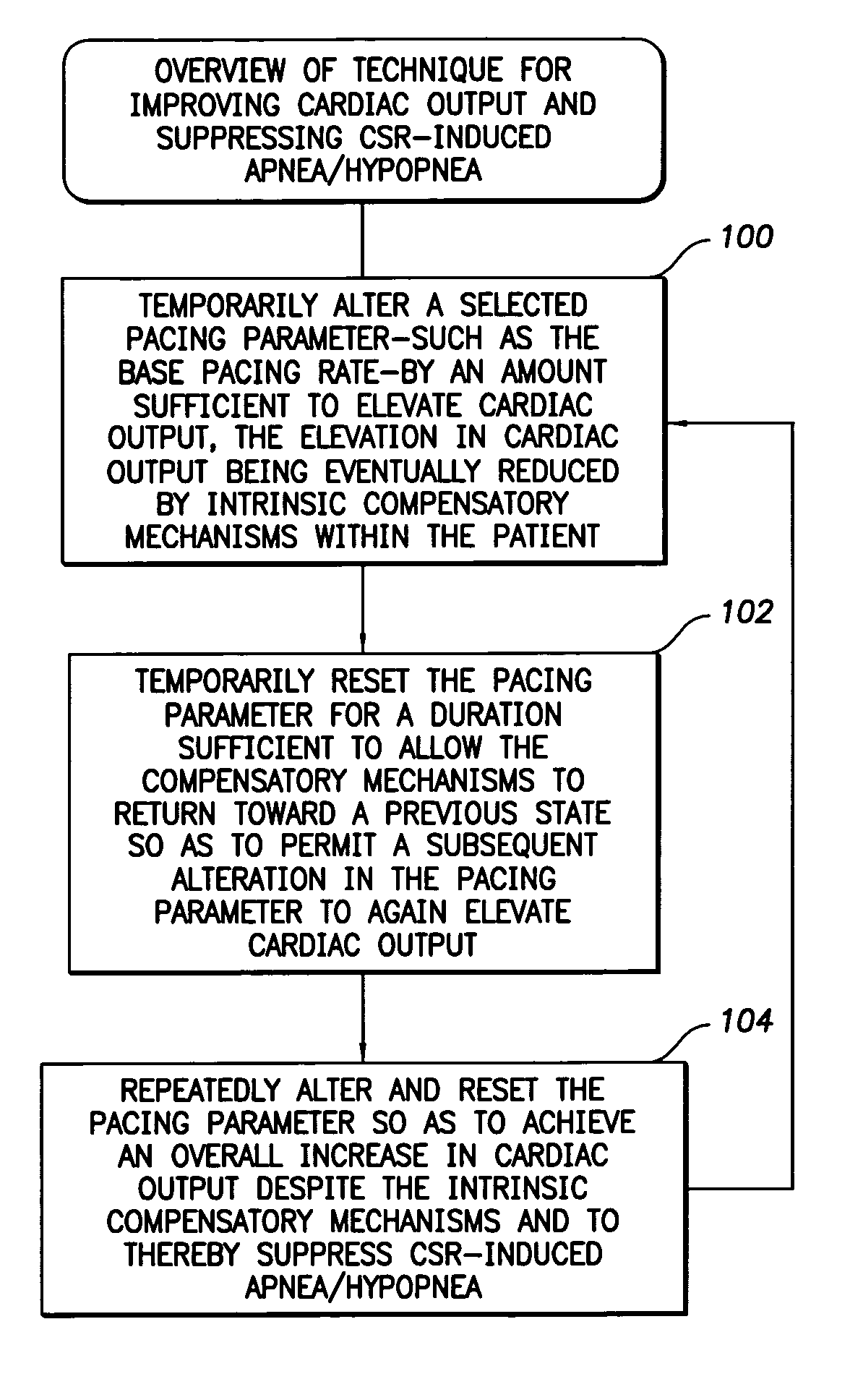

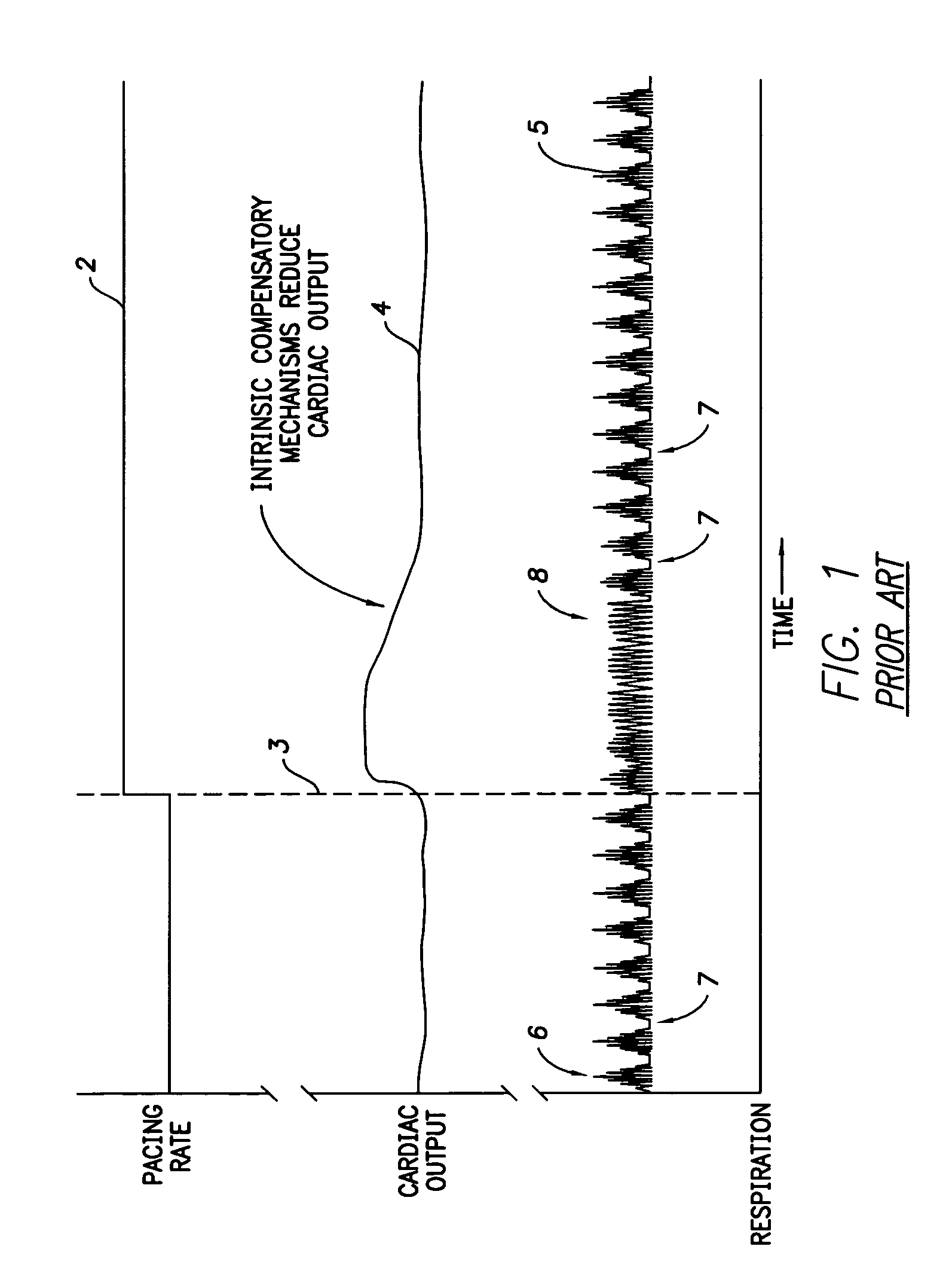

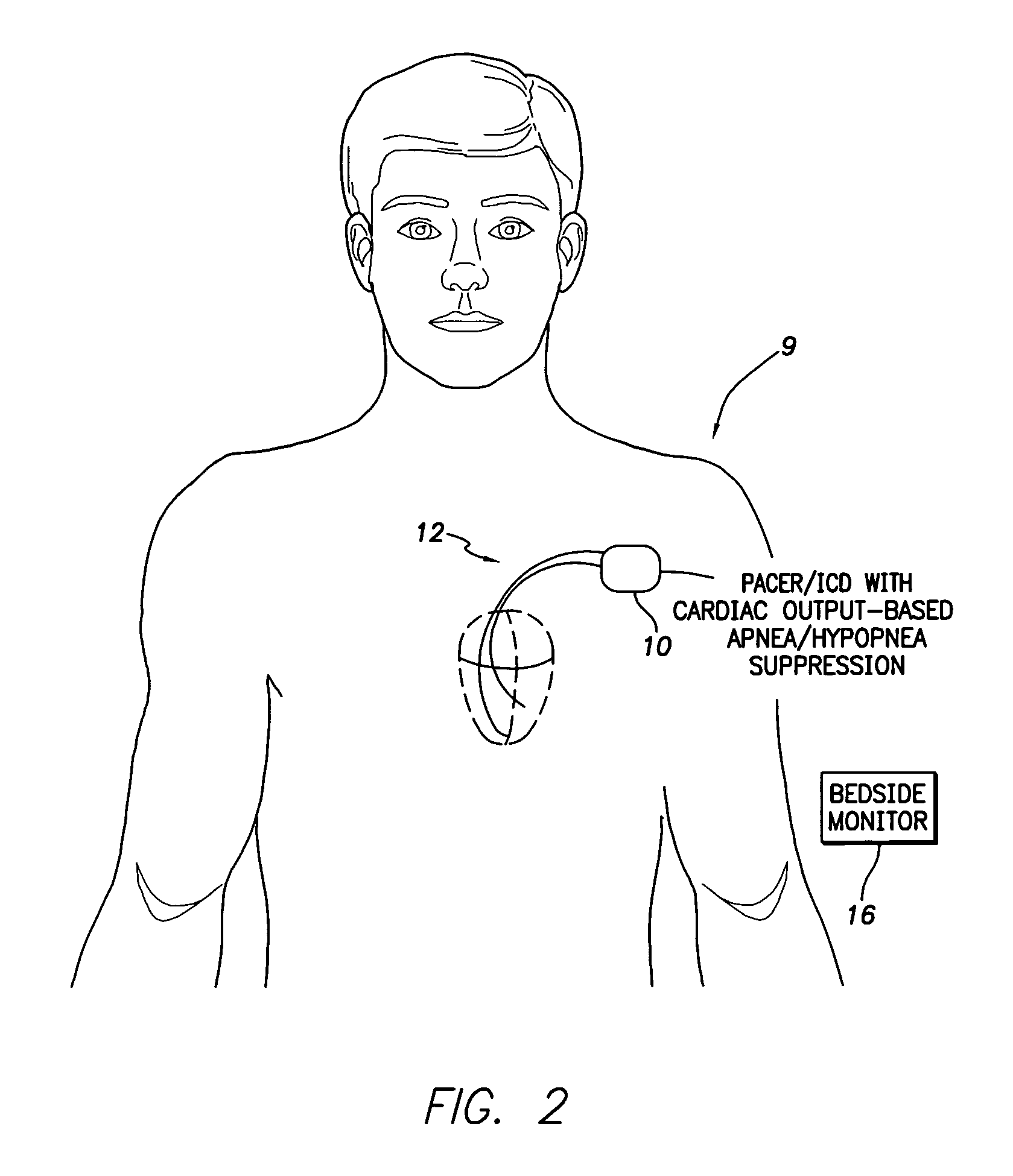

Implantable medical device with cardiac output- based apnea suppression

InactiveUS7706881B1Promote breathingMinimal levelHeart stimulatorsHypopneaCardiac pacemaker electrode

Techniques are provided for improving cardiac output and also suppressing certain forms of apnea / hypopnea within a patient using an implantable medical device, such as a pacemaker or ICD. In one example, a selected pacing parameter—usually the pacing rate—is temporarily altered by an amount sufficient to elevate cardiac output, the elevation in cardiac output being eventually reduced by intrinsic compensatory mechanisms within the patient. The pacing parameter is then temporarily reset for a duration sufficient to allow the compensatory mechanisms to return toward a previous state so as to permit a subsequent alteration in the pacing parameter to again elevate cardiac output. The pacing parameter is repeatedly altered and reset so as to achieve an overall increase in cardiac output despite the intrinsic compensatory mechanisms. The increase in cardiac output is often sufficient to suppress certain forms of apnea / hypopnea, particularly apnea / hypopnea arising from Cheyne-Stokes Respiration (CSR).

Owner:PACESETTER INC

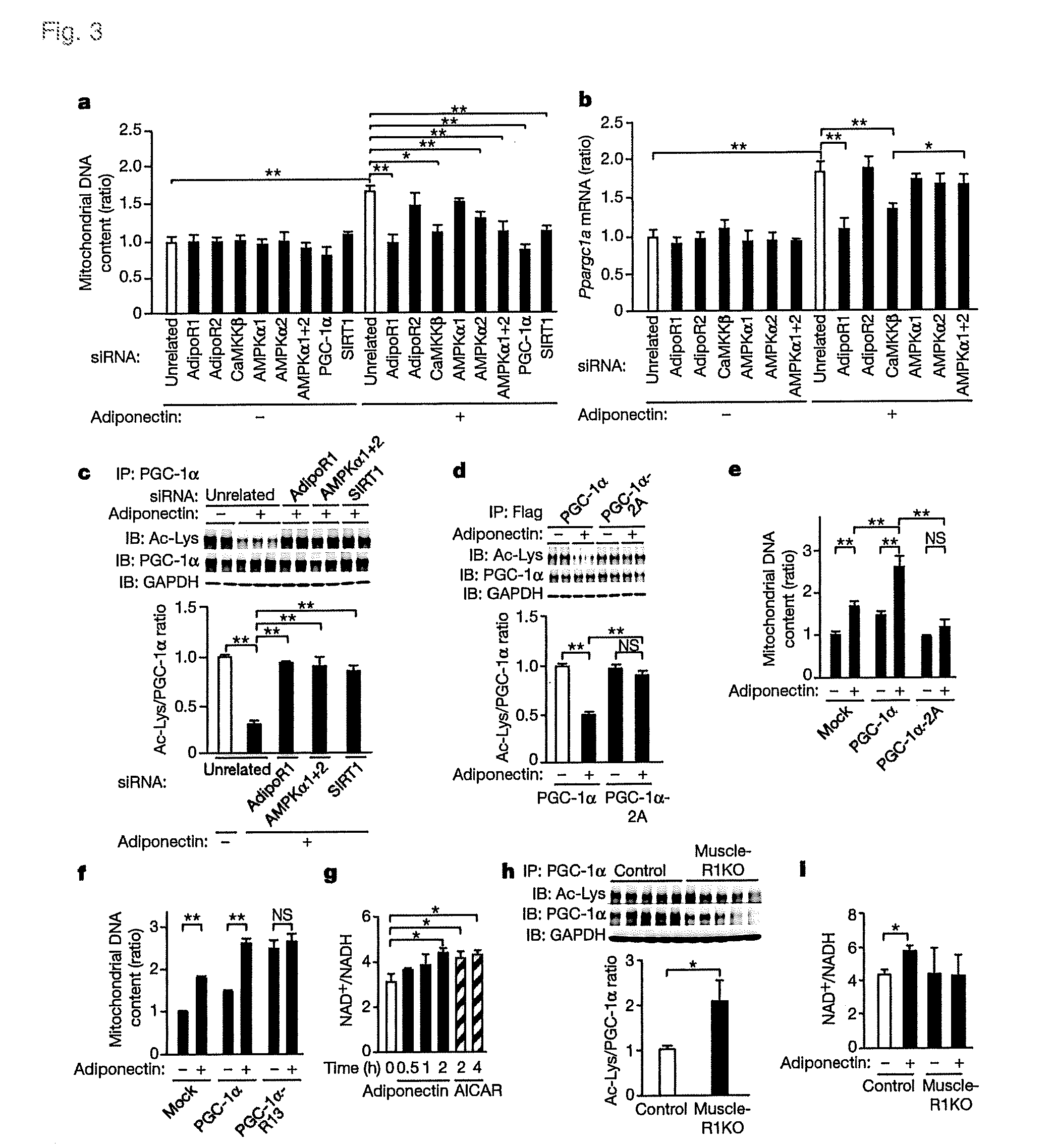

Screening Method for Candidate Agonist Compounds for Adiponectin Receptor I

InactiveUS20130273567A1Screened very easily and preciselyPrevent obesityHormone peptidesPeptide/protein ingredientsAdiponectin ReceptorChemistry

A method of screening for candidate compounds for adiponectin receptor 1 agonist including a step of bringing test compounds into contact with cells to determine whether they cause intracellular influx of extracellular calcium ions and selecting, from the test compounds, compounds causing the intracellular influx of extracellular calcium ions as the candidate compounds for adiponectin receptor 1 agonist.

Owner:THE UNIV OF TOKYO

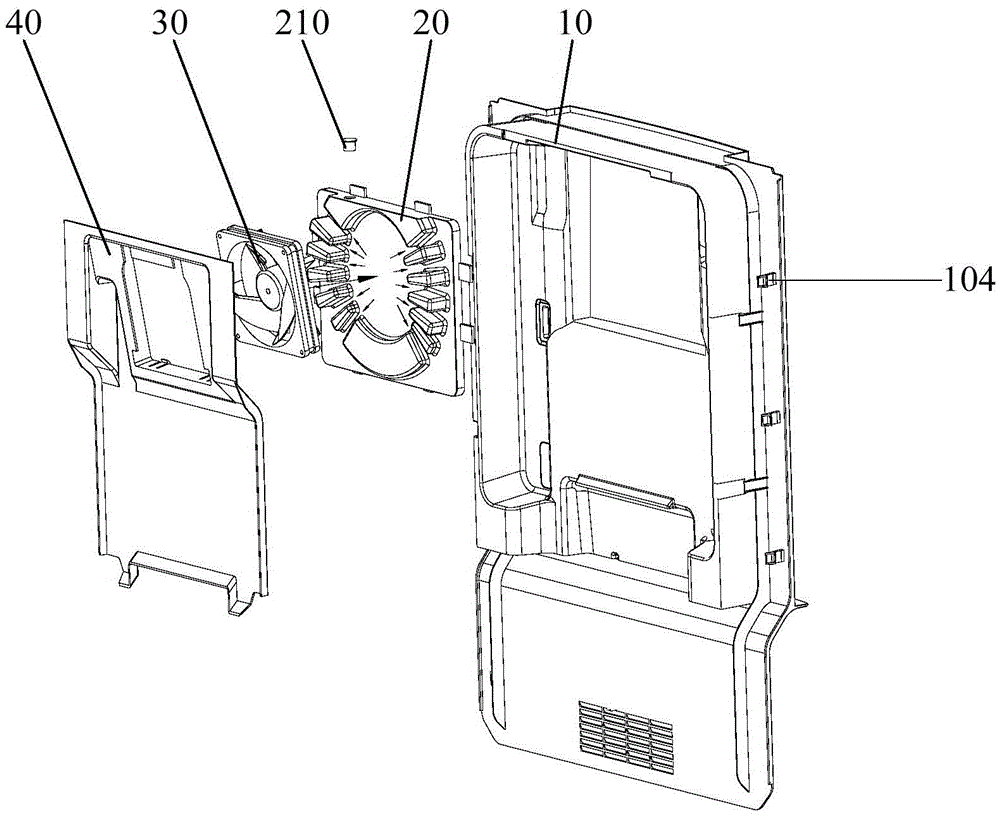

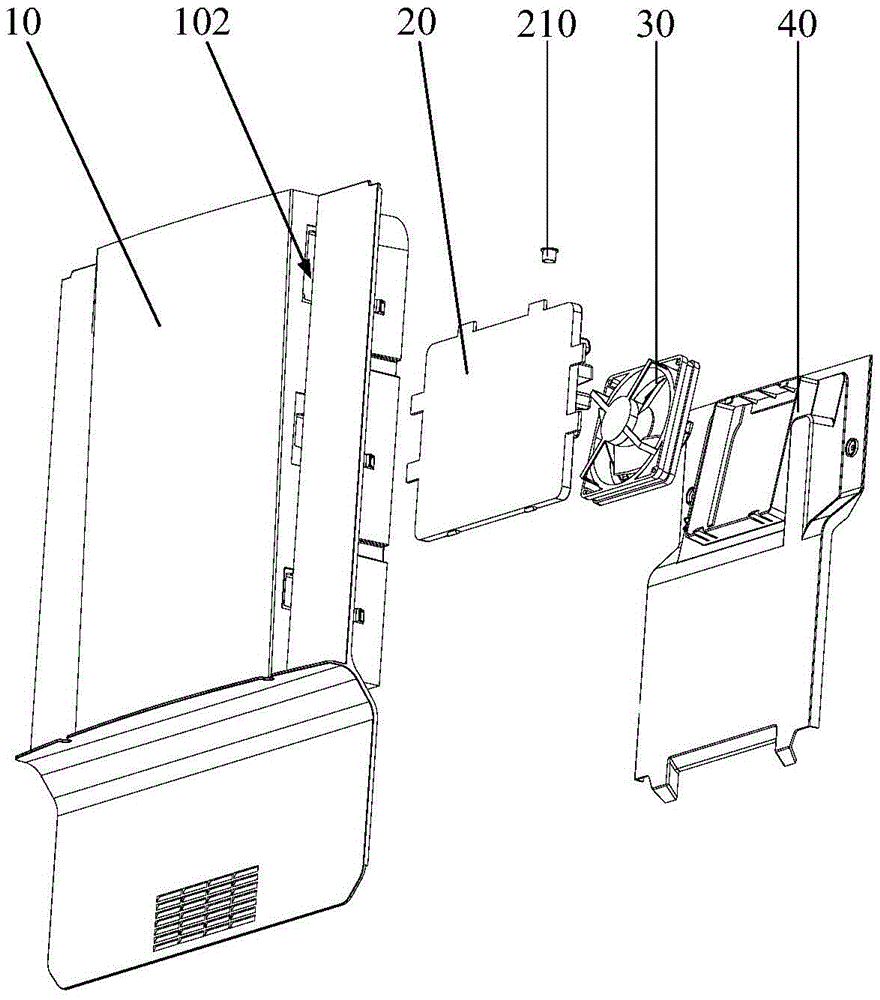

Air flue assembly and refrigerator

ActiveCN105674668AImprove freshnessImprove storage effectLighting and heating apparatusCooling fluid circulationCold airEngineering

The invention provides an air flue assembly which comprises an air flue shell and a cold accumulation box. The air flue shell is provided with a chamber air supply opening, and an air flue is formed by the air flue shell and an inner container of a refrigerator, wherein the cold accumulation box is installed in the air flue. According to the technical scheme, the cold accumulation box is embedded in the air flue, on one hand, the volume of a refrigerator chamber can be prevented from being occupied by the cold accumulation box, and the use experience of a user is improved; and on the other hand, when the refrigerator runs, cold air generated by the refrigerator passes through the cold accumulation box in the air flue firstly before entering the refrigerator chamber, and part of cooling capacity of the cold air is stored through the cold accumulation box, so that the temperature of the cold air entering the refrigerator chamber is increased. When the refrigerator shuts down, the cold capacity in the cold accumulation box can be properly released into the refrigerator chamber according to the temperature in the refrigerator chamber, and increasing of the temperature in the refrigerator chamber can be slowed accordingly. Thus, the fluctuation of the temperature in the refrigerator chamber can be effectively reduced, and the freshness preservation and storage effects of the refrigerator are improved.

Owner:HEFEI HUALING CO LTD +1

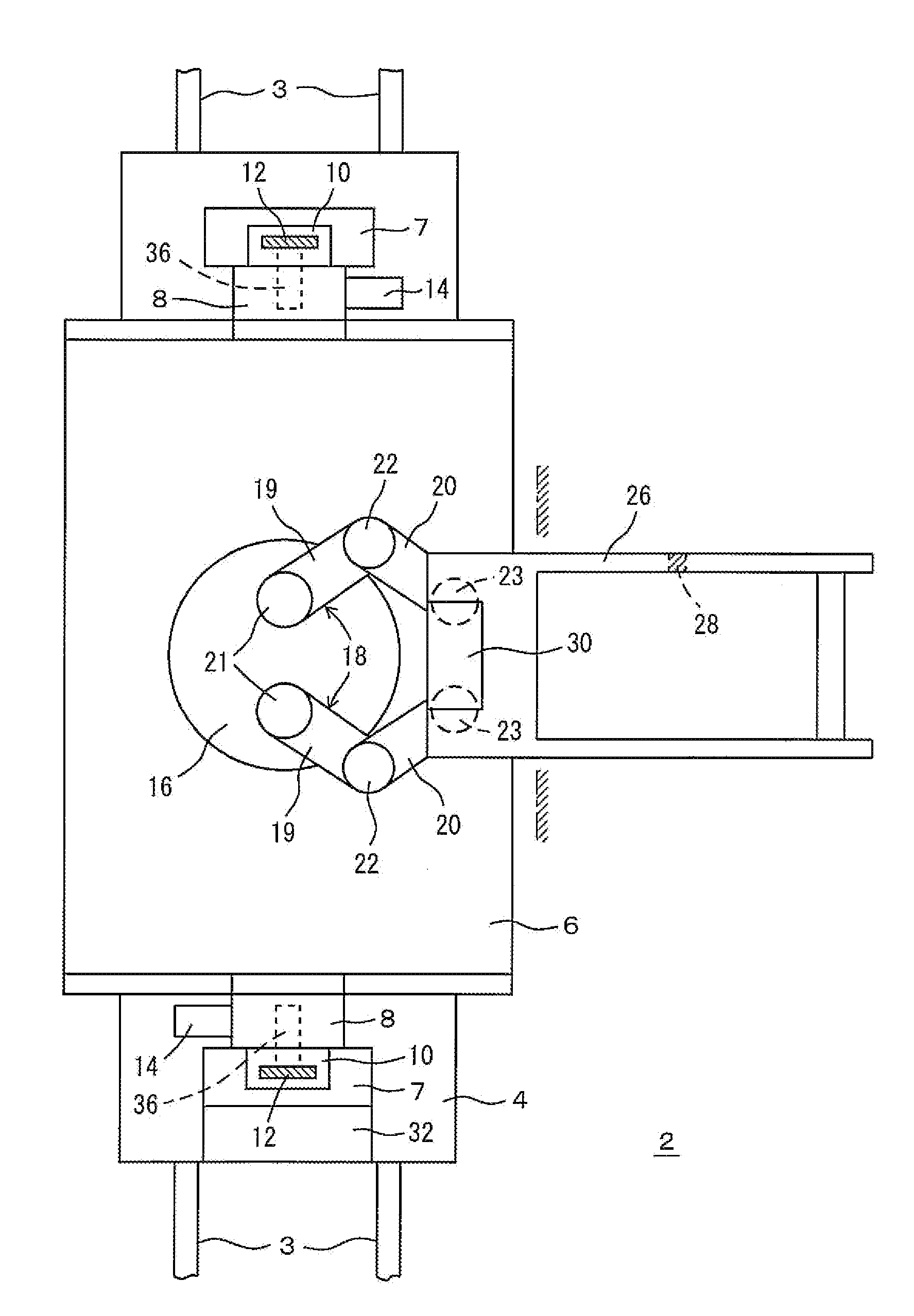

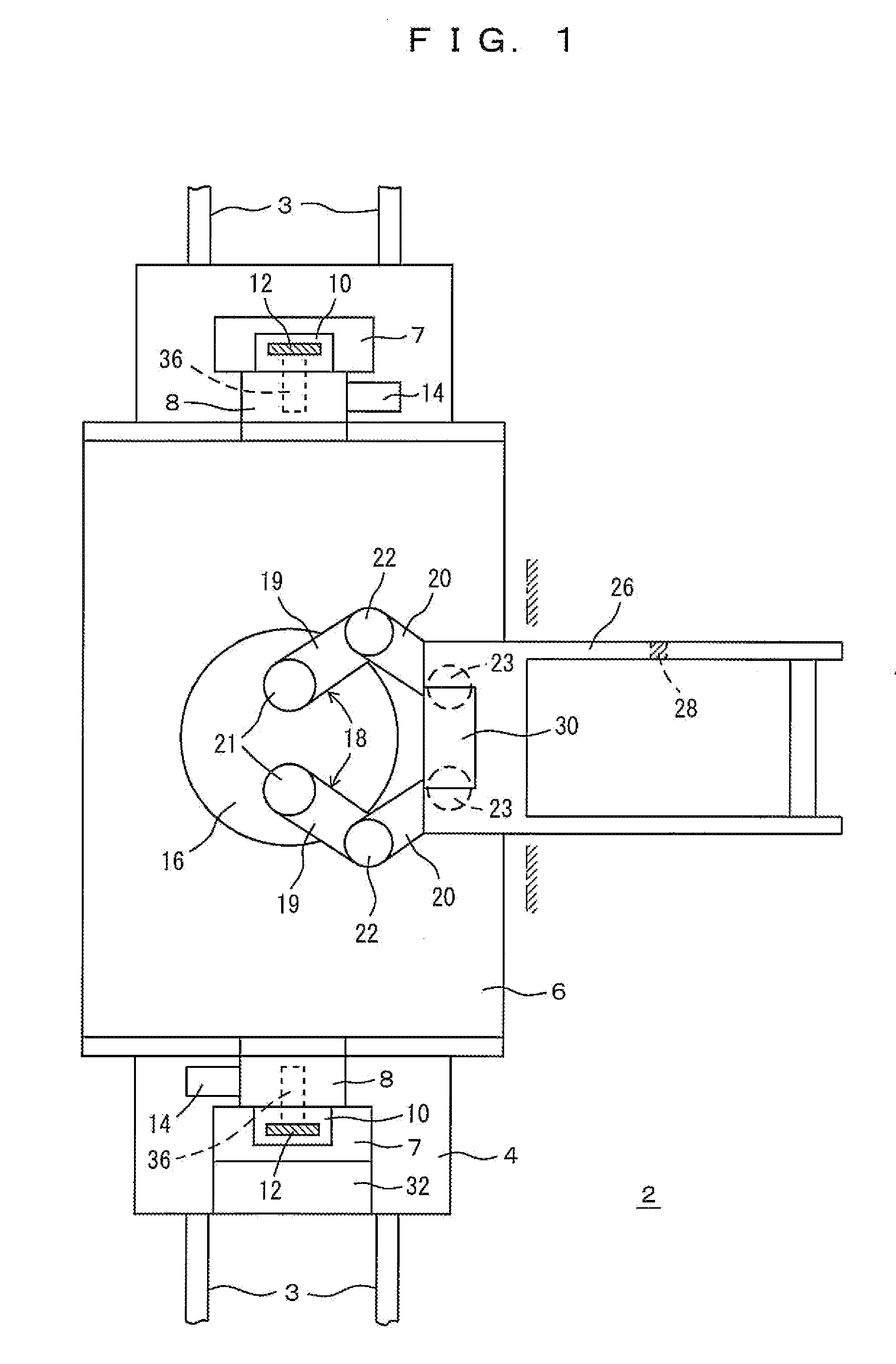

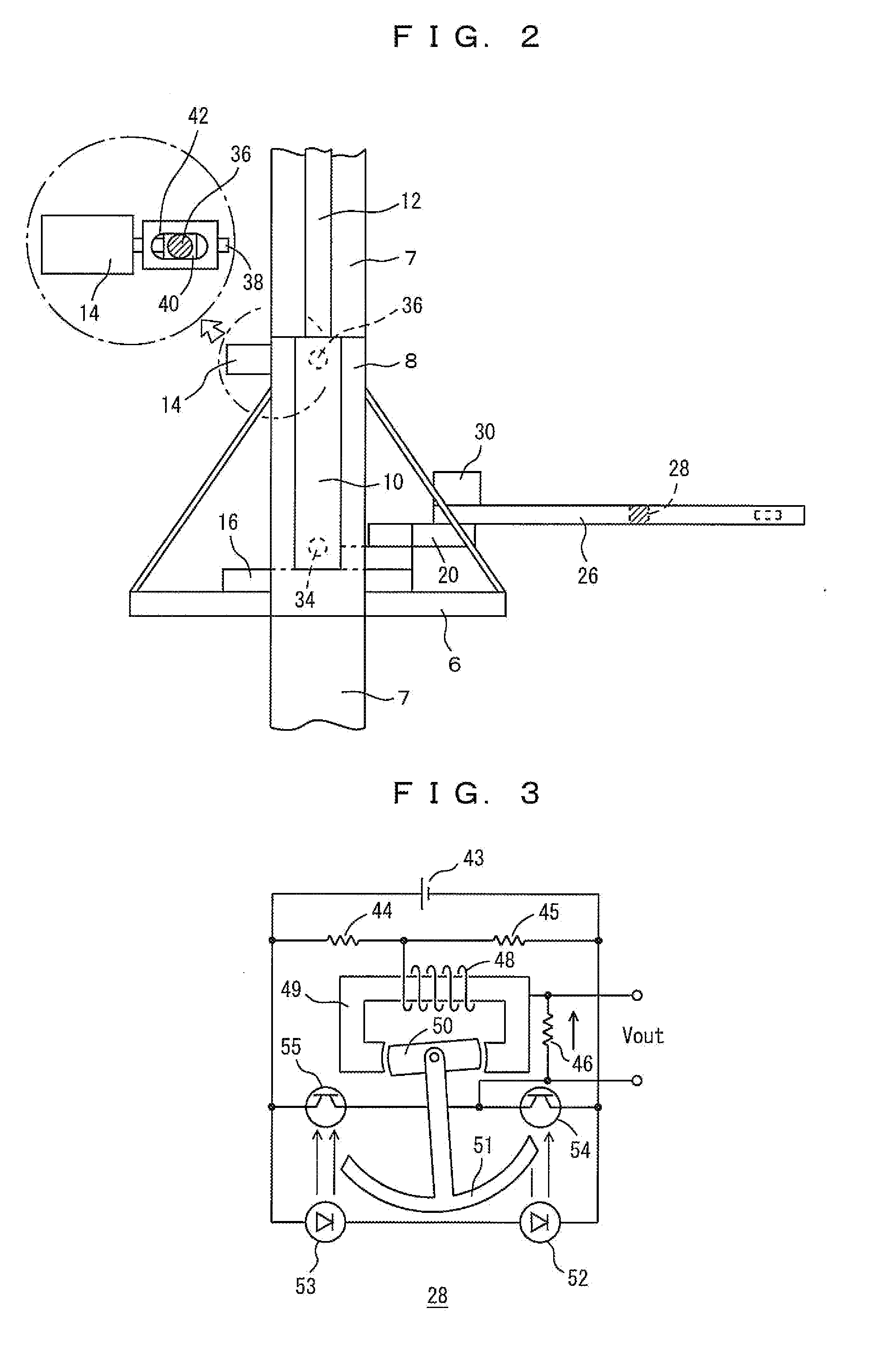

Transfer apparatus and transfer method

In a transfer apparatus, a SCARA arm is provided on an elevation platform. Further, a sensor arranged to detect inclination at a tip end of the arm and a sensor arranged to measure a position of an article on the arm are provided. A base is tilted to eliminate inclination of the detected inclination, and a stretching amount of the arm is corrected in correspondence with the measured position of the article on the arm.

Owner:MURATA MASCH LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com