A processing device for an insulating end ring

A technology of processing device and insulating end, which is applied in the field of transformer manufacturing, can solve the problems of low manufacturing precision, increased cumbersomeness and labor intensity, and can not ensure that the external dimensions of the end ring meet the tolerance requirements of drawings, etc., so as to achieve high work efficiency and save labor. , the effect of small error

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

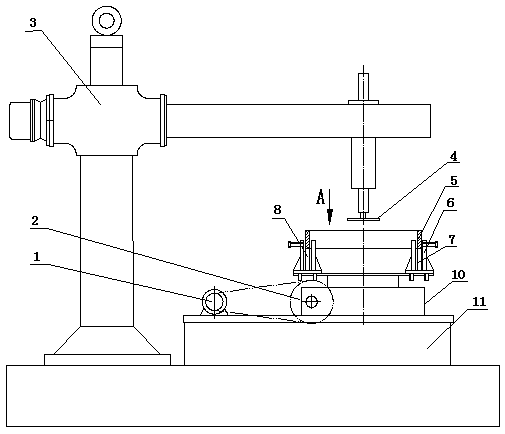

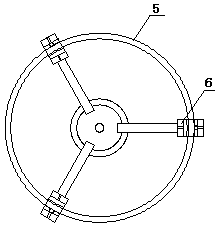

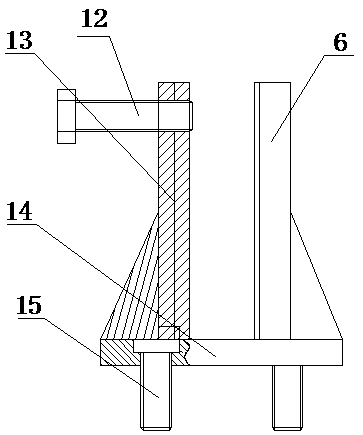

[0015] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 and Figure 7 As shown, this embodiment includes a radial drilling machine 3, three (four, five, etc.) clamping parts 6, three (four, five, etc.) pads 7 , 8, 9, circular milling cutter 4 and rotary table 11. Circular milling cutter 4 is installed on the drill bit position of radial arm drilling machine 3. The rotary table 10 is fixed on the table 11 of the radial drilling machine by bearings through the fixed rotating shaft at its lower end, which is driven to rotate by the motor 1 through the pulley 2 . The clamping part 6 comprises a base plate 14, two vertical clamping plates 13 fixed on the upper end surface of the base plate 14 and a clamping bolt 12 threaded on the left vertical clamping plate 13 (or the right vertical clamping plate), and the lower...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com