Cement prefabricated part direct-extrusion vibration method integral forming mold and machining method thereof

A technology for cement prefabrication and integral molding, applied in molds, manufacturing tools, ceramic molding machines, etc., can solve the problems of complex structural design, poor vibration compactness of complex three-dimensional products, and inability to eliminate bubbles attached to the surface of the mold. The effect of impermeability and strength improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

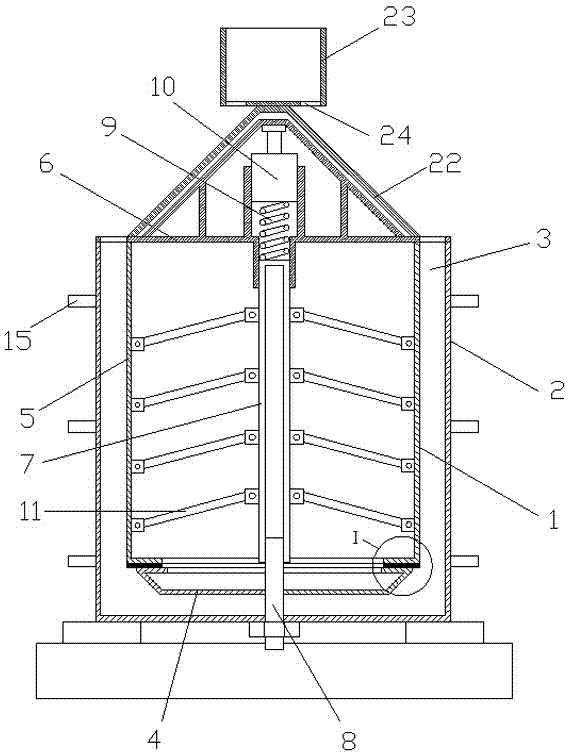

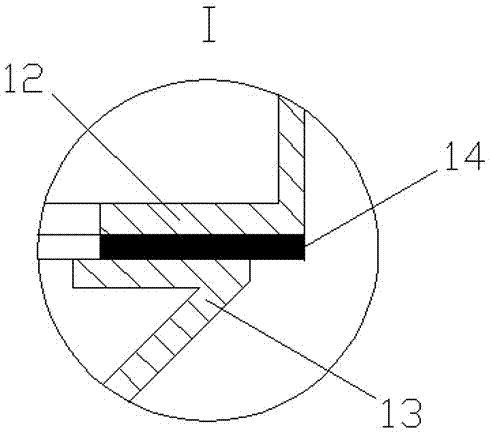

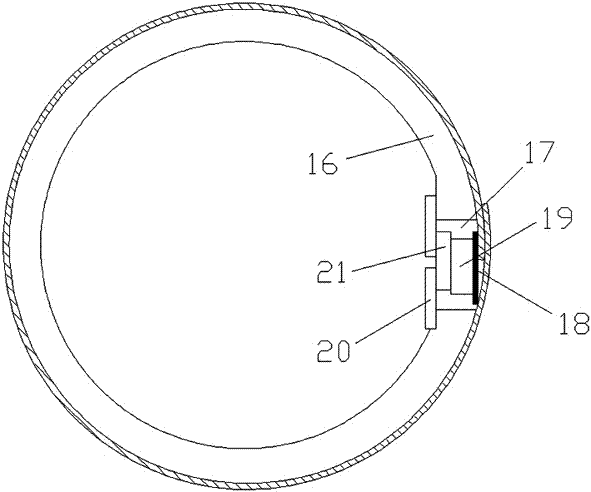

[0032] like Figure 1~3 Embodiment 1 of the present invention is shown: a cement prefabricated part direct extrusion vibration method integral forming mold, including an inner mold 1 and an outer mold 2, both of which are barrel-shaped structures; A cavity 3 for pouring is formed between them. The outer mold is spliced by the two-petal outer mold and the outer bottom film with the joints of the leak-proof slurry and locked by bolt connection. The outer mold and the outer bottom mold have Anti-extrusion ability, located in the inner mold 1, has a tensioning mechanism that pushes the inner mold 1 to expand outward and squeeze downward. When the inner cylinder mold is squeezed, it expands horizontally and also squeezes the inner bottom mold vertically downward. The inner mold 1 includes an inner bottom mold 4 located at the bottom and an inner cylinder mold 5 surrounded by a side wall. The inner cylinder mold 6 is surrounded by steel plates, and the two joints at the joints of ...

Embodiment 2

[0049] like Figure 4 Showing Embodiment 2 of the present invention: the main difference between this embodiment and Embodiment 1 is that the opening and closing mechanism is different. In this embodiment, the bottom of the outer mold is provided with a base, the middle part of the outer mold is straight, and the upper part of the outer mold is Trumpet-shaped structure, the bottom, middle and upper parts of the outer mold are connected by bolts. The inner mold includes an inner top mold 27 located in the upper horn-shaped structure of the outer mold. The inner cylinder mold is located on the outer mold. Inside the straight cylinder in the middle of the mold, a cavity for pouring and tamping concrete is formed between the outer mold and the inner mold, and feed inlets 26 are set on the base, the top of the inner cylinder mold, and around the inner cylinder mold. The iron plate is rolled into a seam overlapped by 5cm, and passes through the inner top mold and the base up and dow...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com