Composition for preparing flexible water permeable brick and flexiblewater permeable brick

A composition and technology of permeable bricks, which are applied to the paving, application, and household appliances paved with prefabricated blocks, can solve the problems of loss of functionality, waste, and many permeable bricks missing edges and corners, etc., to prolong the service life, Improve wear resistance and reduce transportation and construction loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

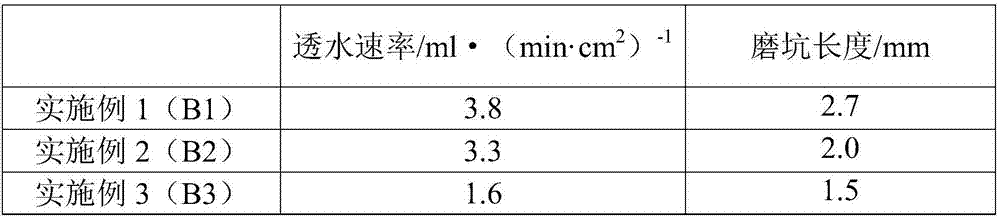

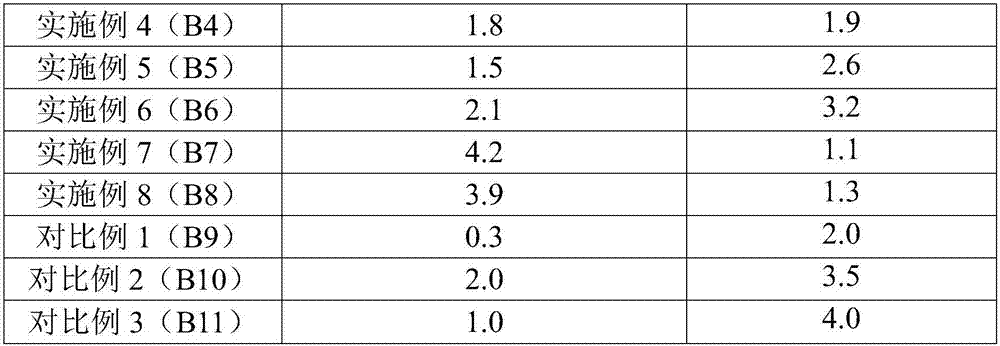

Examples

preparation example Construction

[0033] The preparation method of above-mentioned polyurethane modified epoxy resin can be well known to those skilled in the art, for example can be synthesized according to the method disclosed in (engineering plastic application, 2005,33 (5): 73~76) such as Hu Jiapeng, also can Commercially available, for example, the polyurethane modified epoxy resin can be purchased from Dongguan Tuoxin Composite Materials Co., Ltd., product number TX8810 polyurethane modified epoxy resin.

[0034] Optionally, the polyethersulfone modified epoxy resin can be disclosed according to Zhang Qiang et al. ("Research on Polyethersulfone Modified Epoxy Resin", Shanghai Paint, 2014, 52(3): 10-11) Synthesized by the method. The flexible polyurethane resin can be 8250B two-component polyurethane adhesive purchased from Beijing Gaomeng New Material Company.

[0035]In a preferred embodiment of the present disclosure, the flexible binder is polyurethane modified epoxy resin and polyethersulfone modifi...

Embodiment 1

[0047] This example is used to illustrate the composition of the present disclosure for preparing flexible permeable bricks.

[0048] Get 100 parts by weight of silica sand, 2.1 parts by weight of ME-2 type waterborne epoxy resin (contact angle is 62 °), 0.7 parts by weight of polyurethane modified epoxy resin (elongation at break after curing is 130%) and 1.2 parts by weight The curing agent TX-5501 was mixed uniformly to obtain the composition C1 for preparing flexible permeable bricks in this embodiment.

Embodiment 2

[0050] Get 100 parts by weight of silica sand, 1.67 parts by weight of ME-2 type waterborne epoxy resin (contact angle is 62 °), 1.67 parts by weight of polyurethane modified epoxy resin (elongation at break after curing is 130%) and 0.69 parts by weight The curing agent diethylenetriamine was mixed uniformly to obtain composition C2 for preparing flexible permeable bricks in this embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

| epoxy value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com