Tetrafluoroethylene (TFE) refining method

A refining method and tetrafluoroethylene technology, which are applied in chemical instruments and methods, halogenated hydrocarbon preparation, halogenated hydrocarbon disproportionation separation/purification, etc. The effect of reducing energy consumption and optimizing separation conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

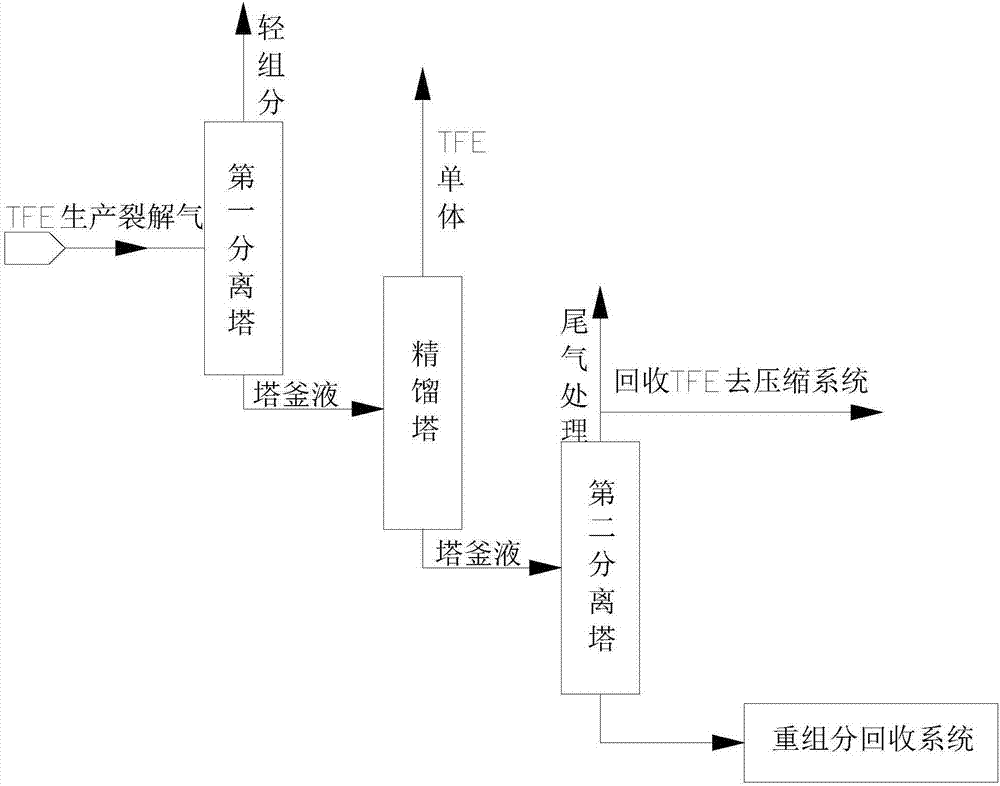

Image

Examples

Embodiment 1

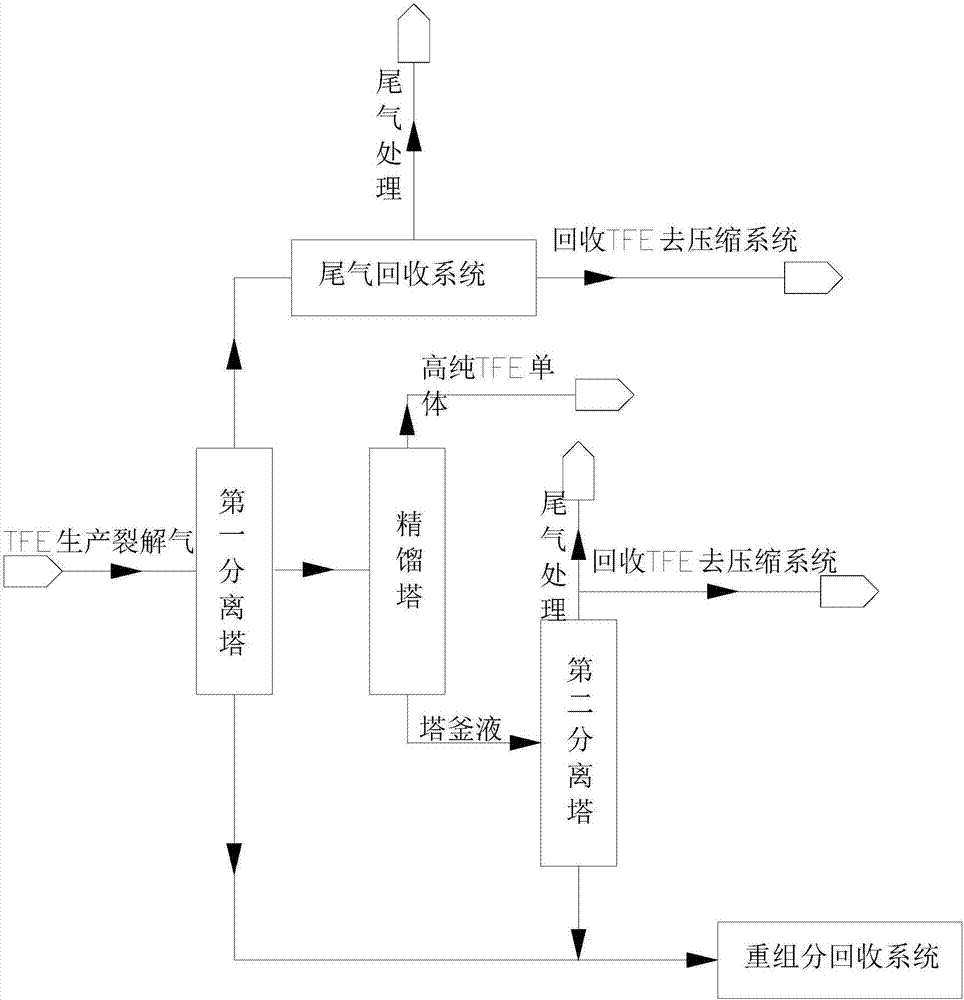

[0043] Please refer to figure 2 , a method for refining tetrafluoroethylene, comprising the steps of:

[0044] Step 1. After the cracked gas produced by TFE is sent to the first separation tower for separation, TFE is recovered from the top gas of the first separation tower, and the crude gas of the first separation tower is discharged from the middle of the first separation tower and then passed into rectification Tower, the liquid in the bottom of the first separation tower enters the heavy component recovery system;

[0045] Wherein, the pressure inside the tower of the first separation tower is controlled at 1.2MPa, and the temperature is controlled at 2.5°C;

[0046] Step 2, after the crude gas of the first separation tower enters the rectification tower for rectification, the TFE monomer is obtained from the top of the rectification tower, and the tower still liquid of the rectification tower enters the second separation tower;

[0047] Among them, the pressure inside...

Embodiment 2

[0051] Please refer to figure 2 , a method for refining tetrafluoroethylene, comprising the steps of:

[0052]Step 1. After the cracked gas produced by TFE is sent to the first separation tower for separation, TFE is recovered from the top gas of the first separation tower, and the crude gas of the first separation tower is discharged from the middle of the first separation tower and then passed into rectification Tower, the liquid in the bottom of the first separation tower enters the heavy component recovery system;

[0053] Among them, the pressure inside the first separation tower is controlled at 1.1MPa, and the temperature is controlled at -15°C;

[0054] Step 2, after the crude gas of the first separation tower enters the rectification tower for rectification, the TFE monomer is obtained from the top of the rectification tower, and the tower still liquid of the rectification tower enters the second separation tower;

[0055] Among them, the pressure inside the rectif...

Embodiment 3

[0059] Please refer to figure 2 , a method for refining tetrafluoroethylene, comprising the steps of:

[0060] Step 1. After the cracked gas produced by TFE is sent to the first separation tower for separation, TFE is recovered from the top gas of the first separation tower, and the crude gas of the first separation tower is discharged from the middle of the first separation tower and then passed into rectification Tower, the liquid in the bottom of the first separation tower enters the heavy component recovery system;

[0061] Wherein, the pressure inside the tower of the first separation tower is controlled at 1.3MPa, and the temperature is controlled at 20°C;

[0062] Step 2, after the crude gas of the first separation tower enters the rectification tower for rectification, the TFE monomer is obtained from the top of the rectification tower, and the tower still liquid of the rectification tower enters the second separation tower;

[0063] Among them, the pressure inside ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com