High-performance adhesive material and preparation method thereof

An adhesive material, high-performance technology, applied in the field of bionic materials, can solve the problems of poor viscosity, narrow application range, high production cost, etc., to achieve the effect of improving adhesion performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

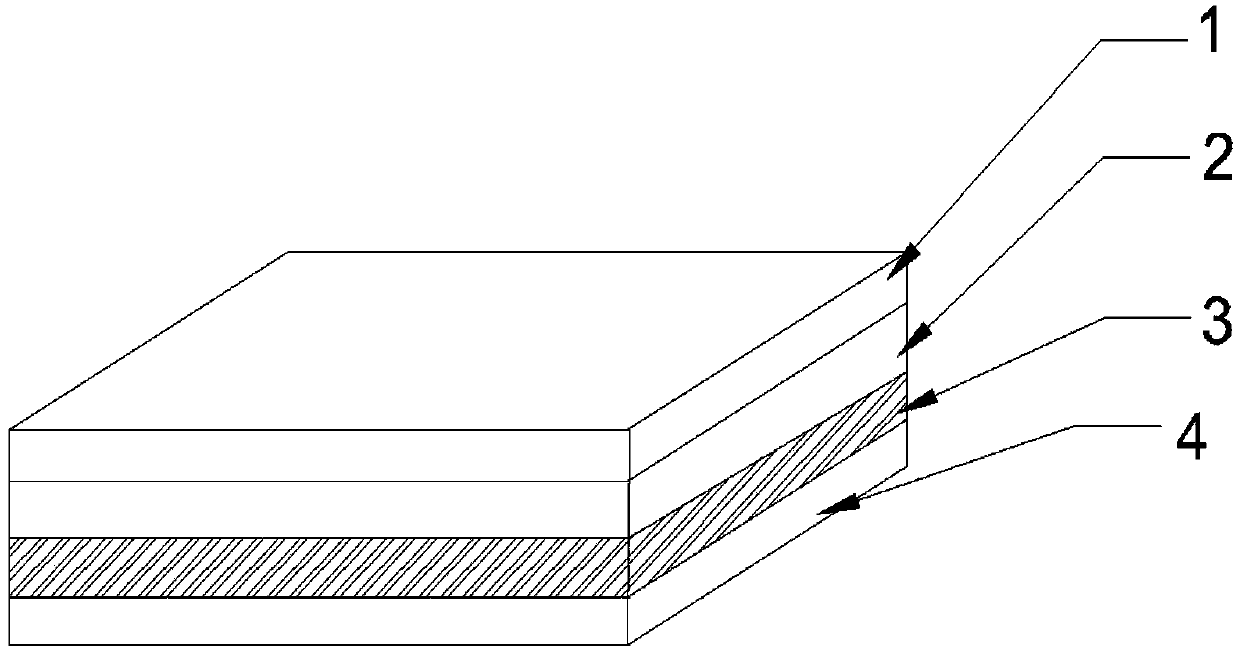

[0022] Example 1 discloses a high performance adhesive material such as figure 1 As shown, it is composed of four layers of material structure. The four layers of materials are bottom-up PMDS layer 4, carbon fiber cloth layer 3, top PDMS layer 2 and elm bark mucus layer 1, bottom PDMS layer 4 and top PDMS layer. 2 are the same material and are made by mixing liquid silicone rubber and silicone rubber curing agent. The material used in elm bark slime layer 1 is elm bark mucus; wherein, the mass ratio of liquid silicone rubber and silicone rubber curing agent is 10:1. The preparation method of the high-performance adhesive material in embodiment 1 comprises the following preparation steps:

[0023] 1) elm bark treatment, cut a certain amount of elm bark, rinse its surface with distilled water; then put the clean elm bark into a beaker filled with distilled water to soak, the mass ratio of elm bark to distilled water is about 1:50;

[0024] 2) Extraction of elm bark mucus, put m...

Embodiment 2

[0028] Embodiment 2 discloses a kind of high-performance adhesive material, and it is made up of four-layer material structure, and four-layer material is bottom layer PMDS layer 4, carbon fiber cloth layer 3, top layer PDMS layer 2 and elm bark mucus layer successively from bottom to top 1. The bottom PDMS layer 4 and the top PDMS layer 2 are made of the same material and are mixed with liquid silicone rubber and silicone rubber curing agent. The material used in the elm bark mucus layer 1 is elm bark mucus; wherein, liquid silicone rubber and silicon rubber The mass ratio of rubber curing agent is 10:1. The preparation method of the high-performance adhesive material in this embodiment comprises the following preparation steps:

[0029] 1) elm bark treatment, cut a certain amount of elm bark, rinse its surface with distilled water; then put the clean elm bark into a beaker filled with distilled water to soak, the mass ratio of elm bark to distilled water is about 1:50;

[0...

Embodiment 3

[0033] Embodiment 3 discloses a kind of high-performance adhesive material, and it is made up of four-layer material structure, and four-layer material is bottom layer PMDS layer 4, carbon fiber cloth layer 3, top layer PDMS layer 2 and elm bark mucus layer successively from bottom to top 1. The bottom PDMS layer 4 and the top PDMS layer 2 are made of the same material and are mixed with liquid silicone rubber and silicone rubber curing agent. The material used in the elm bark mucus layer 1 is elm bark mucus; wherein, liquid silicone rubber and silicon rubber The mass ratio of rubber curing agent is 10:1. The preparation method of the high-performance adhesive material in this embodiment comprises the following preparation steps:

[0034] 1) elm bark treatment, cut a certain amount of elm bark, rinse its surface with distilled water; then put the clean elm bark into a beaker filled with distilled water to soak, the mass ratio of elm bark to distilled water is about 1:50;

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com