Processing method of 6063 aluminum alloy for appearance parts of electronic products

A technology of electronic products and processing methods, applied in the field of non-ferrous metals, can solve the problems of anodizing "material grain, affecting the use of materials, etc., achieve good anodizing effect, broad market application prospects, and improve the effect of anodizing effect."

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

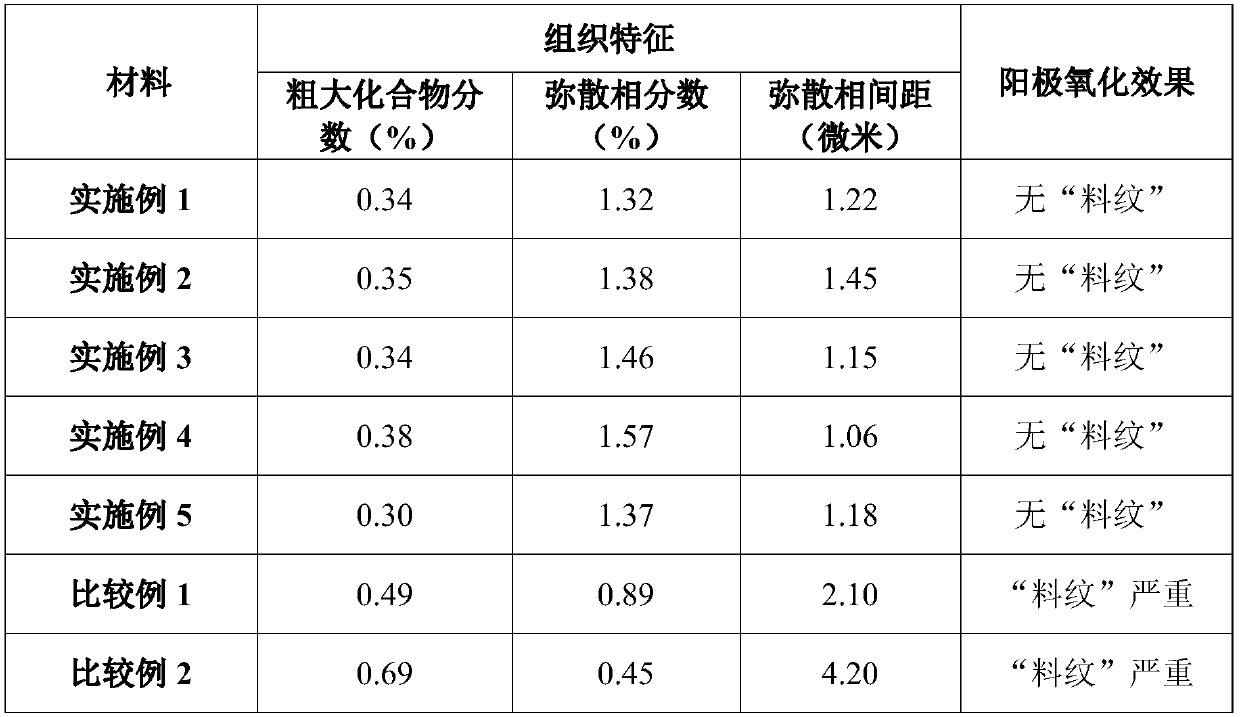

Examples

Embodiment 1

[0022] The 6063 ingot is kept at 330°C for 6 hours, then at 460°C for 5 hours, and then at 560°C for 6 hours; the homogeneous ingot is hot-rolled, the rolling temperature is 500°C, and the final rolling temperature is 260°C; Cold rolling, solution treatment, and aging treatment are carried out; in the material anodic oxidation sandblasting process, No. 203 zircon sand is used.

Embodiment 2

[0024] The 6063 ingot is kept at 380°C for 4 hours, then at 480°C for 3 hours, and then at 570°C for 4 hours; the homogeneous ingot is hot-rolled, the rolling temperature is 520°C, and the final rolling temperature is 300°C; Then cold rolling, solution treatment, and aging treatment are carried out; in the anodic oxidation sandblasting process of the material, No. 205 zircon sand is used.

Embodiment 3

[0026] The 6063 ingot is kept at 320°C for 8 hours, then at 420°C for 6 hours, and then at 550°C for 8 hours; the homogeneous ingot is hot-rolled, the rolling temperature is 460°C, and the final rolling temperature is 240°C; Then cold rolling, solution treatment, and aging treatment are carried out; in the anodic oxidation sandblasting process of the material, No. 170 zircon sand is used.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com