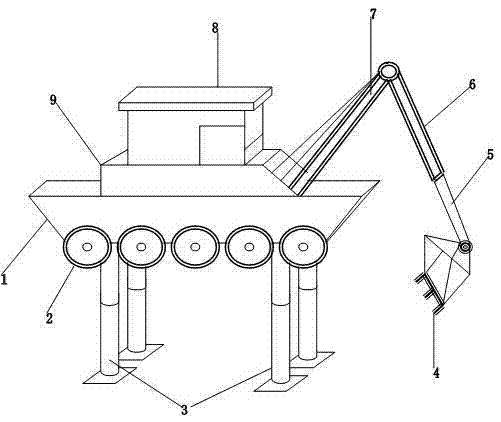

Three-dimensional energy-efficient excavation machine

A high-efficiency energy-saving, excavation machinery technology, applied in the field of machinery

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example

[0019] Drive the three-dimensional high-efficiency and energy-saving excavation machine to the land or water surface construction site. If land construction is carried out, the high-efficiency excavation work can be carried out by operating in the driving control room 8 according to the operation mode of an ordinary land excavation rig. If excavation and dredging constructions such as general shallow water surface and ditches are carried out, only the floating wheel 2 switch needs to be opened in the control room 8 to drive the floating hull 1 into shallow water areas and ditches, and only the floating wheel 2 or the floating hull 1 can be used. Or use the buoyancy of the floating wheel 2 and the floating hull 1 to support the body simultaneously and carry out the construction with the operation mode of the common drilling rig. If the construction in deep water area, the hydraulic switch in the control room 8 can be used to extend the water column 3 from the floating hull 1 sect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com