Integral die forged 151mm pitch pin track and scraper conveyer

A technology of integral mould and rail plate, applied in the direction of slitting machinery, underground transportation, transportation and packaging, etc., can solve the problems of rapid wear and tear of the traction system, frequent failures, and inability to achieve two-way coal cutting, so as to reduce organizational defects and improve the overall Longevity and the effect of improving the load-carrying capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

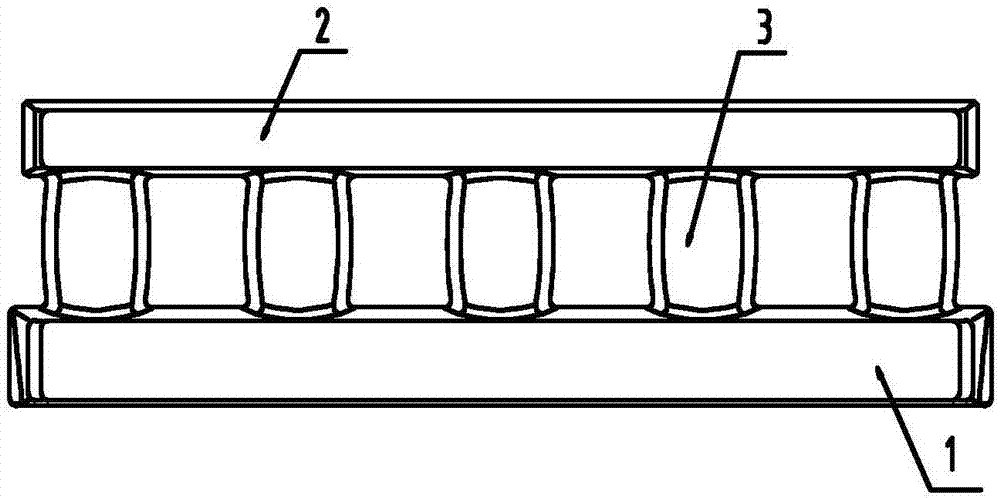

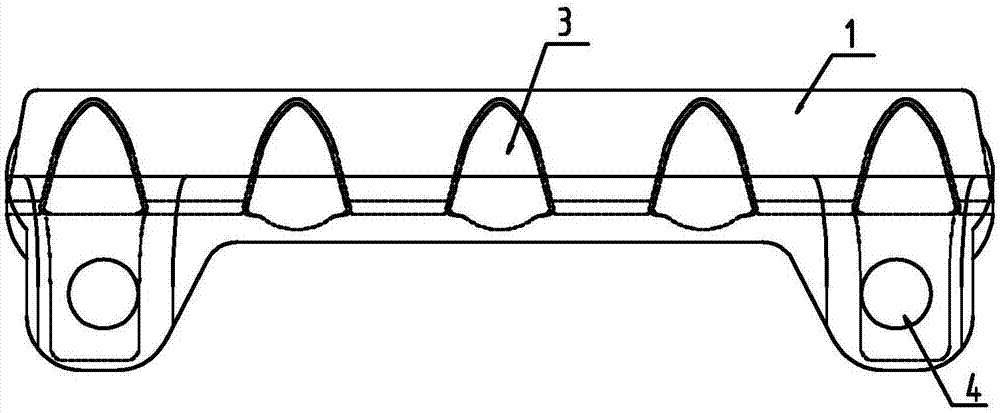

[0023] Such as Figure 1-3 As shown, an integral die forging 151mm pitch pin rail includes a main rail plate 1, an auxiliary rail plate 2 and a plurality of pin teeth 3, the main rail plate 1 and the auxiliary rail plate 2 are arranged in parallel, and the plurality of pins The teeth 3 are arranged at equal intervals between the main rail plate 1 and the auxiliary rail plate 2, the distance between adjacent pin teeth 3 is 151 mm, and the pin teeth 3 are set to 5, which is especially suitable for the middle slot with a slot length of 1500 mm It is used on the road, and the traction force that the conveyor can withstand is increased by increasing the pitch and the cross-sectional area of the pin tooth 3, thereby improving the overall life of the pin rail.

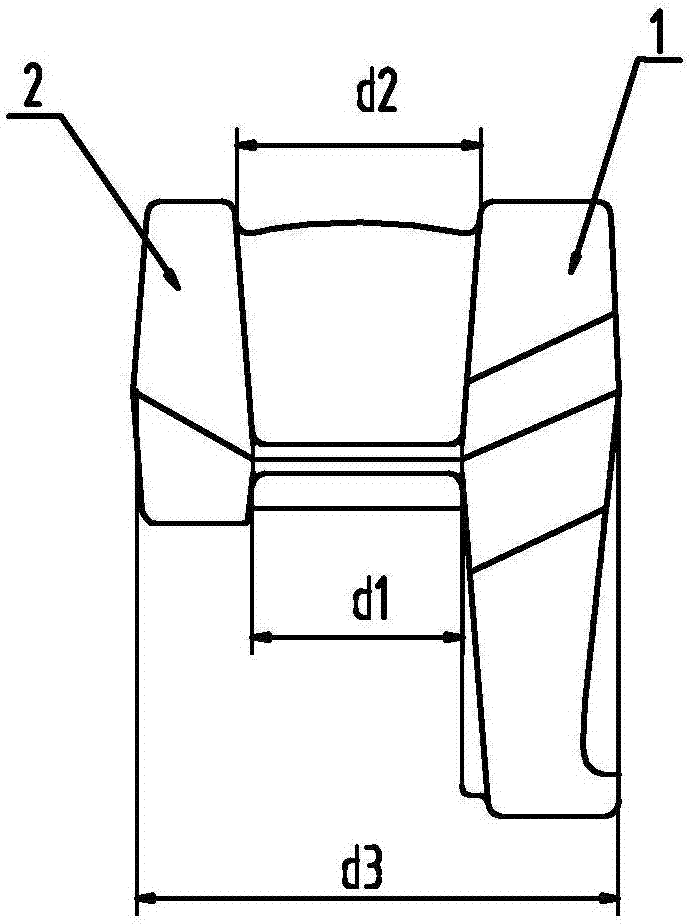

[0024] The main rail plate 1, auxiliary rail plate 2 and pin teeth 3 are formed at one time through the integral die forging process to reduce the structural defects of the material. The tooth shape of the pin teeth 3 is ob...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com