Socket and spigot joint pipeline anti-seismic connector

A socket type and pipeline technology, which is applied in the field of anti-seismic pipe joints and anti-seismic joints, can solve the problems of complex processing, poor ability to resist large deformation under earthquake action, inconvenient installation on site, etc., and achieve the effect of improving lateral shear stiffness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

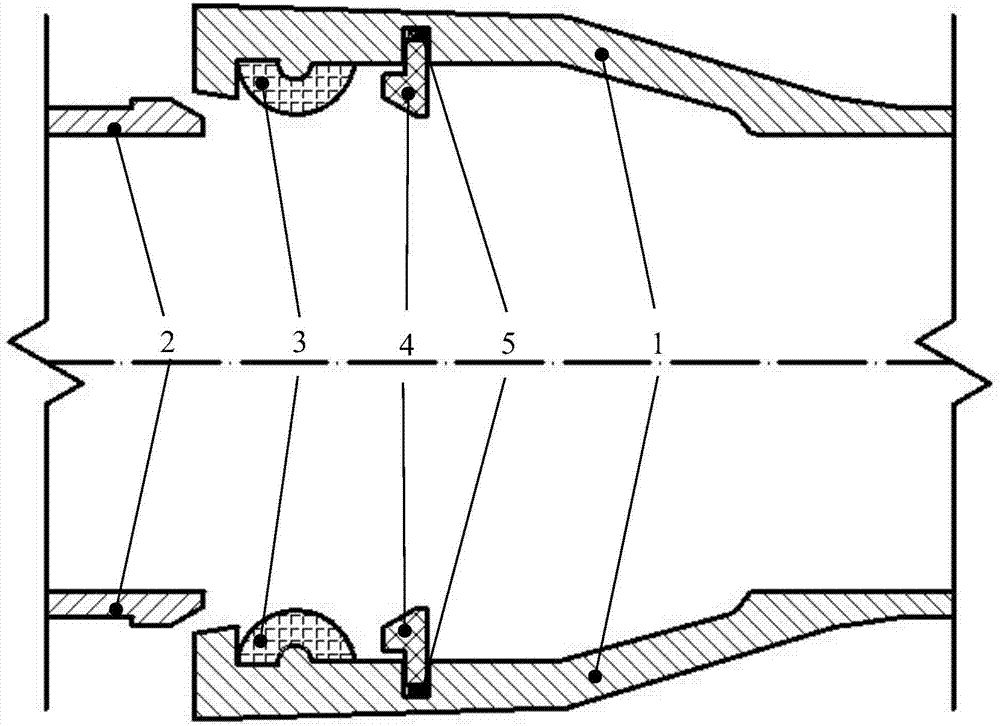

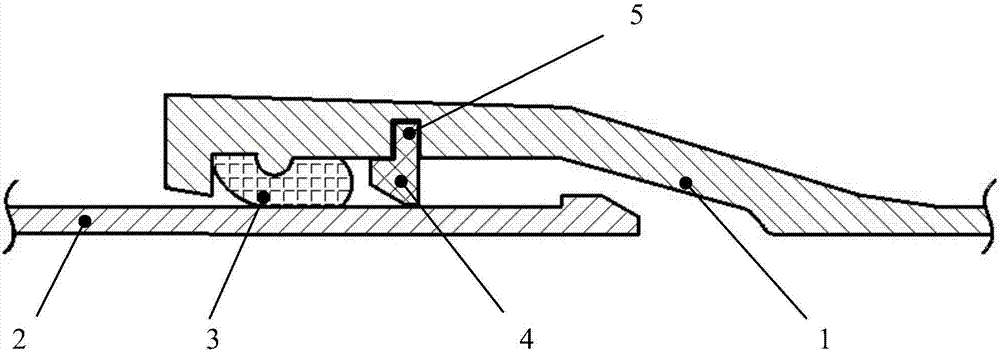

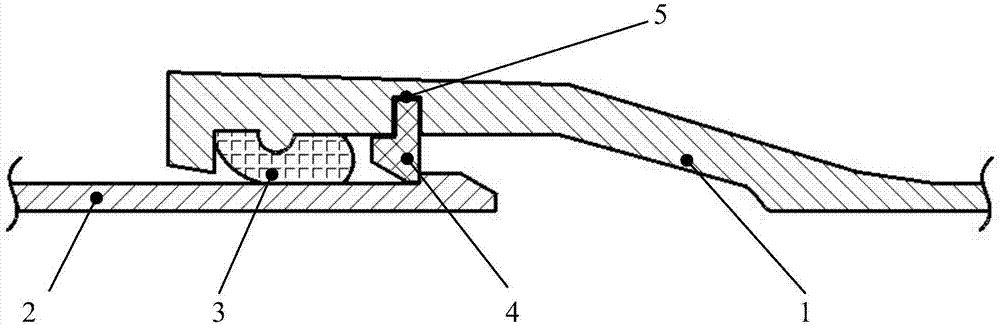

[0045] The present invention is described in detail below in conjunction with the accompanying drawings: the anti-seismic pipeline interface comprises a pipeline socket (1), a pipeline socket (2), a water-stop rubber ring (3), and a metal stop ring (4). See attached figure 1 , attached figure 2 , attached image 3 , attached Figure 4 , attached Figure 5 .

[0046] First install the rubber gasket (5) in the groove of the pipe socket;

[0047] Install the three circular arcs that make up the metal limit ring (4) in the groove of the pipe socket (1) in sequence. After the three rings are assembled into a complete ring, they can be firmly stuck on the pipe socket ( 1) in the groove;

[0048] Then install the water-stop rubber ring (3) on the raised position of the pipe socket (1);

[0049] After installing the water-stop rubber ring (3), insert the pipe socket (2) into the pipe socket (1), and apply a layer of lubricant to the water-stop rubber ring (3) and the metal sto...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com