Active wood drying method

A drying method and wood drying technology, applied in the direction of wood drying, drying gas arrangement, local stirring and drying machine, etc., can solve the problems affecting the utilization of fast-growing wood and solid wood.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

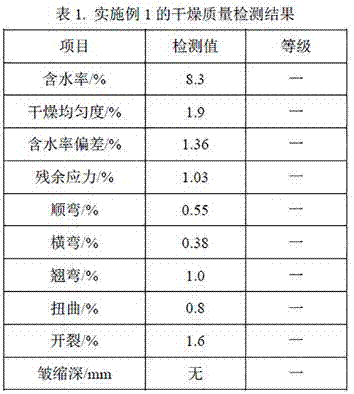

[0029] Embodiment 1: The tree species selected in this embodiment is fast-growing poplar, and the initial moisture content is 92%. The saw is made into a thickness of 30mm, a length of 2000mm, and a width of 200mm. Follow the steps below to dry fast-growing poplar.

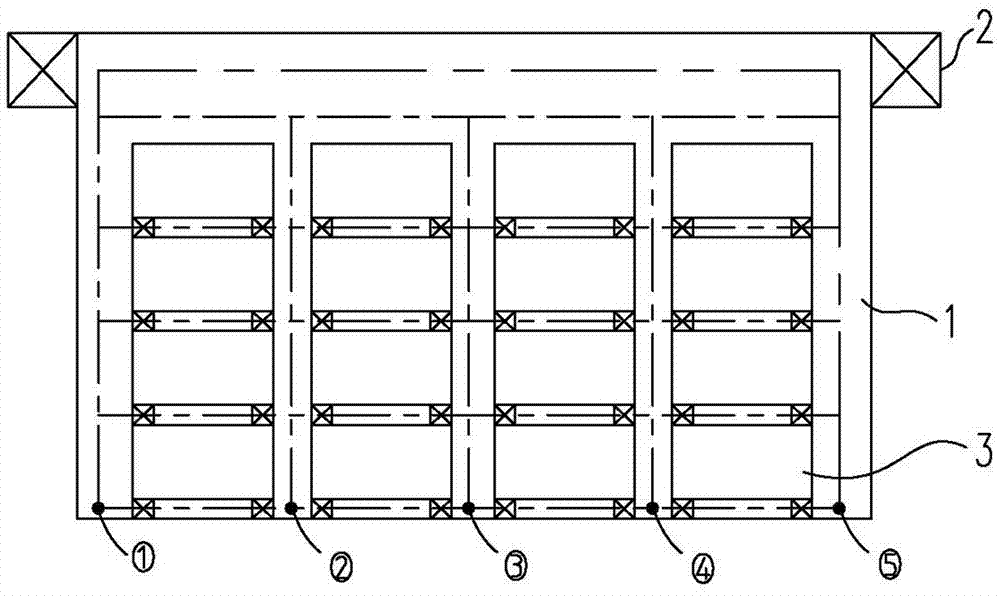

[0030] (1) Stacking and kiln loading, separate and stack the wood with a spacer with a thickness of 25mm. The pile of timber is 2000mm long, 1000mm wide, and 1000mm high. .

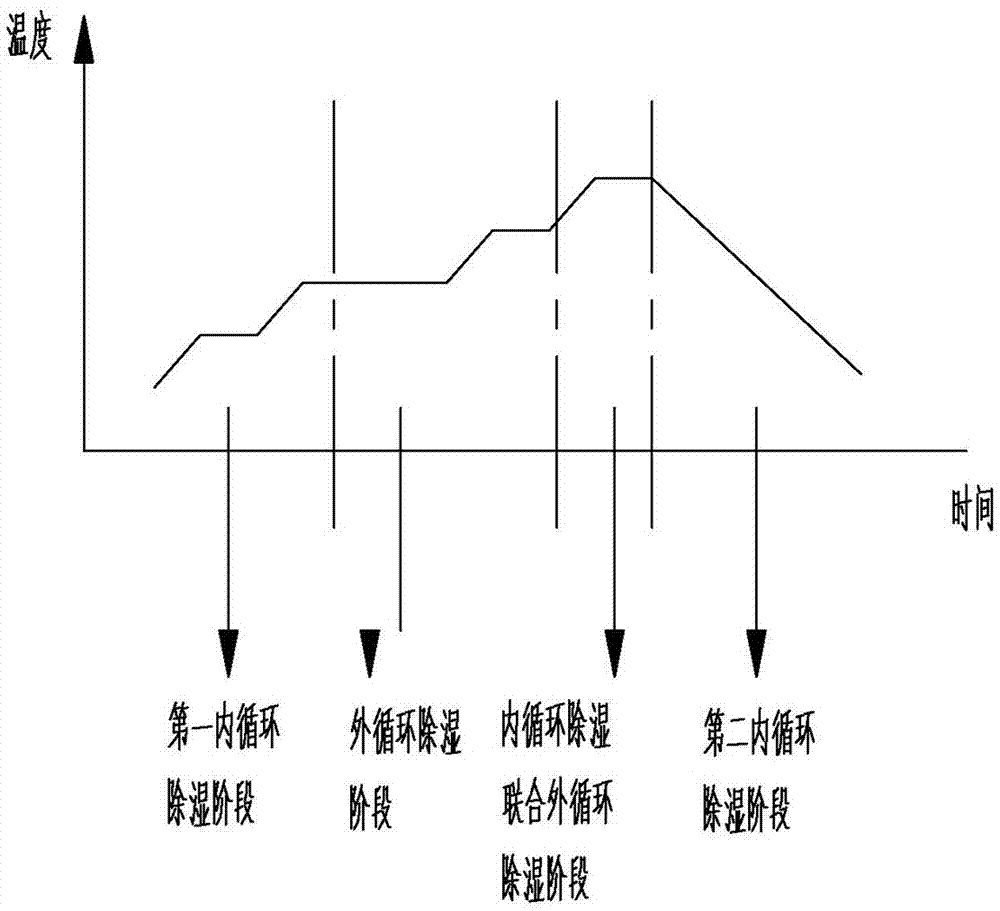

[0031] (2) When the moisture content of poplar sawn timber is greater than 40%, place a dehumidifier between the piles, and use the dehumidifier to circulate dehumidification to discharge the moisture evaporated from the wood in the drying kiln. The temperature of the drying medium is 40°C and the relative humidity is 70%. , the air circulation velocity is 5 m / s.

[0032] (3) When the moisture content of the poplar sawn timber is dried to 40%, the internal circulation dehumidification and drying are stopped, and the moisture evaporated fro...

Embodiment 2

[0038] Embodiment 2: The tree species selected in this embodiment is fast-growing eucalyptus, with an initial moisture content of 86%. The saw is made into a thickness of 45mm, a length of 2000mm, and a width of 150mm.

[0039] (1) Stacking and kiln loading, separate and stack the wood with a spacer with a thickness of 25mm. The pile of timber is 2000mm long, 1000mm wide, and 1000mm high. .

[0040] (2) When the moisture content of eucalyptus sawn timber is greater than 40%, a dehumidifier is placed between the wood pile and the wall of the drying kiln, and the moisture evaporated from the wood in the drying kiln is discharged by circulating dehumidification in the dehumidifier. The temperature of the drying medium is 35°C , The relative humidity is 85%, and the air circulation speed is 3 m / s.

[0041] (3) When the moisture content of eucalyptus sawn timber is dried to 40%, stop the internal circulation dehumidification and drying, and use the drying kiln dehumidification wi...

Embodiment 3

[0047] Embodiment 3: The tree species selected in this embodiment is fast-growing eucalyptus, with an initial moisture content of 90%. The saw is made into a thickness of 30mm, a length of 2000mm, and a width of 150mm.

[0048] (1) Stacking and kiln loading, separate and stack the wood with a spacer with a thickness of 25mm. The pile of timber is 2000mm long, 1000mm wide, and 1000mm high. .

[0049] (2) When the moisture content of the eucalyptus sawn timber is greater than 40%, a dehumidifier is placed between the wood pile and the wall of the drying kiln, and the moisture evaporated from the wood in the drying kiln is discharged by circulating dehumidification in the dehumidifier. The temperature of the drying medium is 38°C , The relative humidity is 80%, and the air circulation speed is 4 m / s.

[0050] (3) When the moisture content of eucalyptus sawn timber is dried to 40%, stop the internal circulation dehumidification and drying, and use the drying kiln dehumidificatio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com