Combined platform for gravity center measurement and correction for paddle of controllable-pitch propeller

A technology of pitch control propellers and blades, which is applied in the direction of measuring devices, testing of machines/structural components, static/dynamic balance testing, etc. It can solve problems such as tilting of measuring frames, overloading of weighing sensors, time-consuming, etc., and achieve Prevent the blade from moving, reduce the measurement error, and reduce the effect of the error

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0068] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific preferred embodiments.

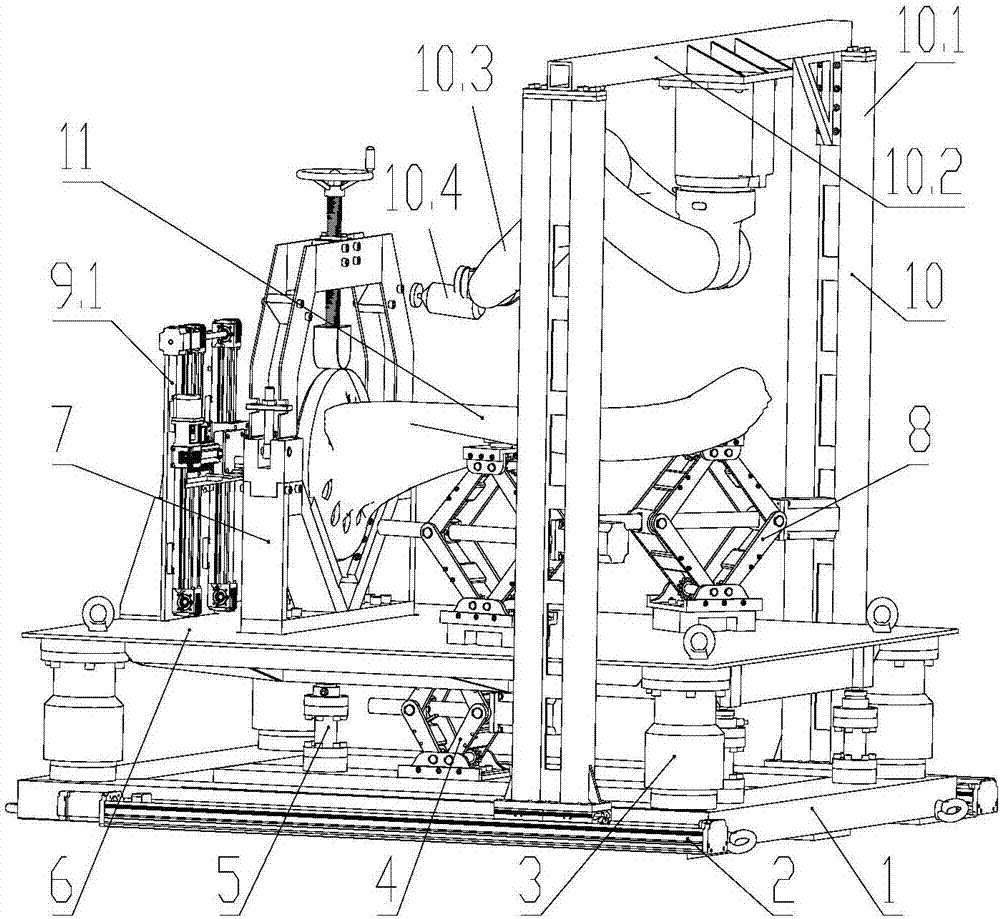

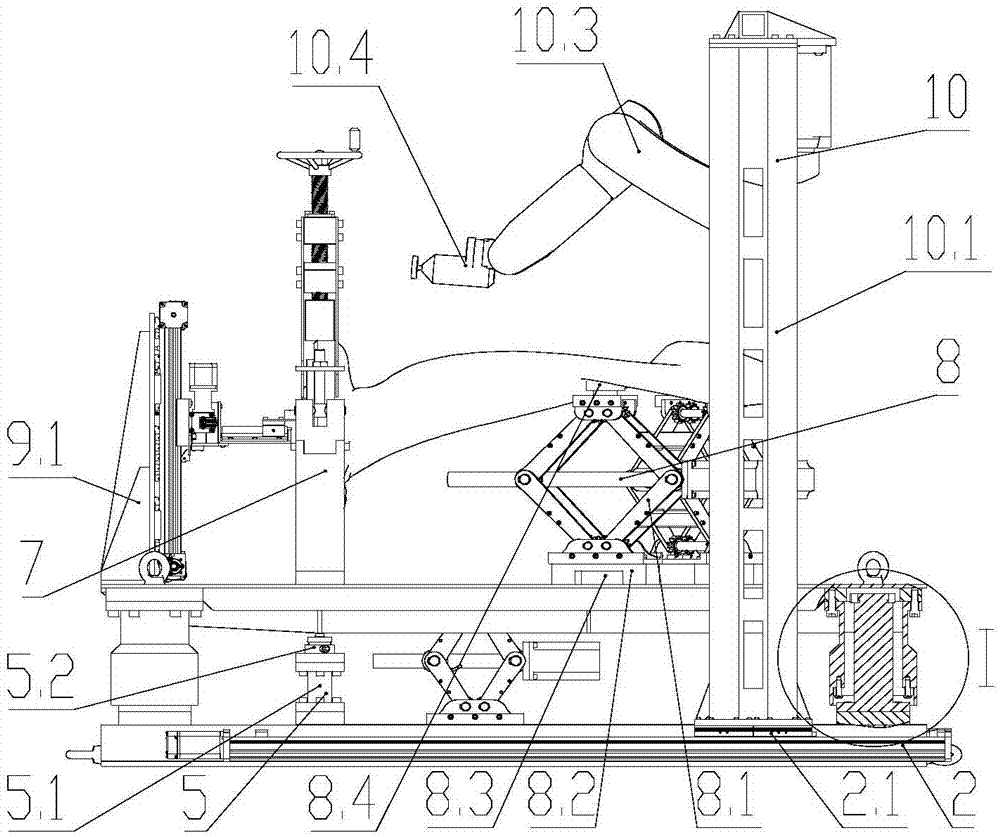

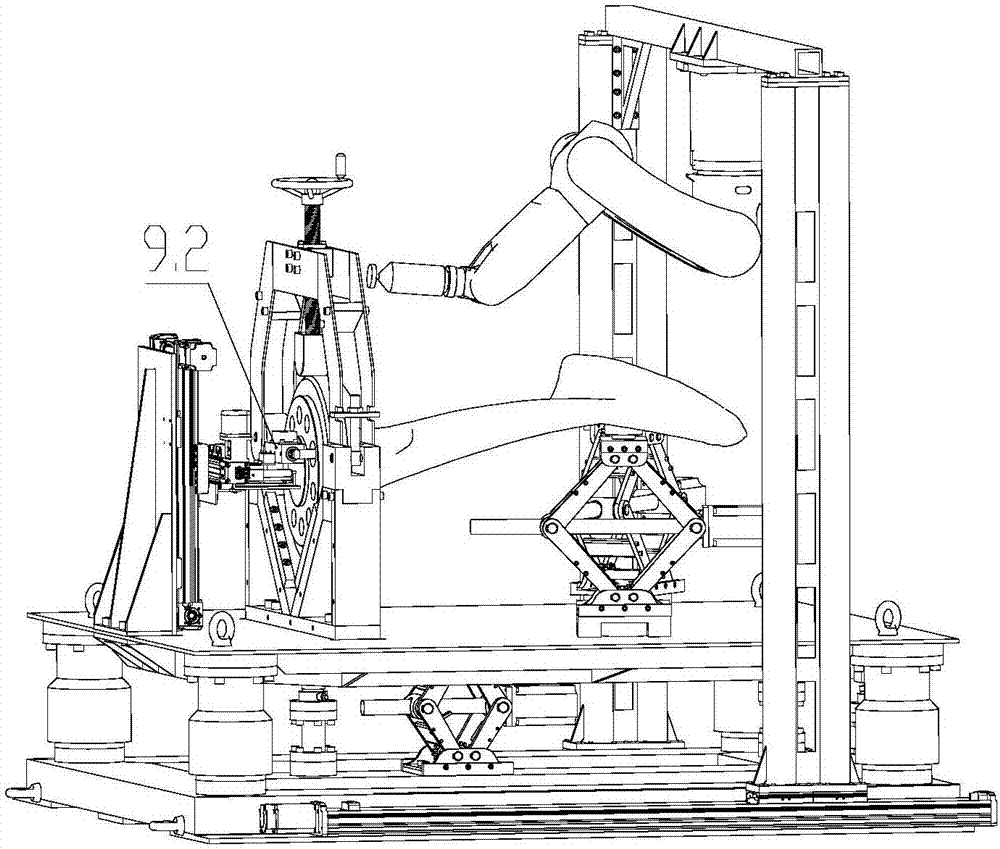

[0069] Such as figure 1 , figure 2 and image 3 As shown, a composite platform for measuring and correcting the center of gravity of the blade of the adjustable pitch propeller, including the machine base 1, the guide assembly 3, the lifting mechanism 4, the weighing assembly 5, the measuring table 6, the clamp assembly 7, the blade A support assembly 8 , a blade space attitude measuring device and a grinding device 10 .

[0070] The measuring workbench is arranged directly above the machine base through the lifting mechanism one, and the height of the measuring workbench can be raised and lowered.

[0071] Lifting mechanism one is preferably an electric jack or an electric screw jack or the like. The measuring table, the lifting mechanism 1 and the machine base are preferably coaxially arranged.

[0072] The setting o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com